Crayon

Background

The earliest form of recorded communication is graphic art, beginning with drawings scratched on the walls of caves by prehistoric peoples. Cave dwellers had limited drawing tools, perhaps only pieces of carbon left over from a cooking fire. Today's graphic communicator can, of course, purchase a variety of far more efficient tools, including the common crayon.

Crayons are made from paraffin, a waxy substance derived from wood, coal, or petroleum. Paraffin was produced commercially by 1867, and crayons appeared around the turn of the century. The early crayons were black and sold mainly to factories and plants, where they were used as waterproof markers. Colored crayons for artistic purposes were introduced in Europe around the same time, but like the black crayons, they contained materials that were toxic (usually charcoal and wax) and thus were not appropriate for children. The Binney & Smith Company, who still make crayons, had a canny grasp of the American educational market, having previously marketed dustless chalk for chalkboards. This company sold its first package of eight colored crayons, suitable for use in schools by children, in 1903.

Raw Materials

Crayons are made of paraffin mixed with various chemical pigments. Paraffin is delivered to the crayon factory in liquid form; delivery trucks must maintain a wann enough temperature to keep the paraffin from hardening (paraffin becomes liquid at about 135°F [57°C]).

Because paraffin will not mix with water or water mixtures, the pigments are in powdered form, although they may have been made from a water mix and then dried. Pigments are made by suppliers following formulas dictated by the crayon manufacturer. Individual pigments are made of chemicals mixed together in wooden tanks and forced through filters to remove excess water, leaving chunks of the individual pigments. The pigments are then kiln-dried for several days. After drying, the chunks of pigment are mixed according to the formula for the desired color, pulverized into a powder, and blended for color consistency. The mixes are sent to the crayon factory.

Over the past 10 years, additional ingredients have been added to crayons. One of the most popular is glitter, small pieces of reflective material that make the crayon-produced work shine as it catches and reflects random beams of light. Perfumes and other scents can also be added to the mix.

The Manufacturing

Process

Crayon manufacturing is a simple process, but one which is still relatively labor intensive. In the American market, the predominant manufacturer is the Binney & Smith Company of Pennsylvania, which manufactures more than two billion crayons a year.

Mixing the batch

-

1 The paraffin is pumped into supply tanks outside the crayon factory.

Each tank holds about 17,000 gallons (65,875 1) of liquid. When the

process begins, the paraffin is piped into small, heated tubs with a

volume of about 6 gallons (23 1) (about the size

of a home washing machine). At the same time, or soon after, a pigment or mixture of pigments is added to give a batch of crayons a particular color.

Paraffin is pumped into supply tanks outside the crayon factory. Each tank holds about 17,000 gallons of liquid. When the process begins, the paraffin is piped into small, heated tubs with a volume of about 6 gallons.

Paraffin is pumped into supply tanks outside the crayon factory. Each tank holds about 17,000 gallons of liquid. When the process begins, the paraffin is piped into small, heated tubs with a volume of about 6 gallons.

Mixing and molding

-

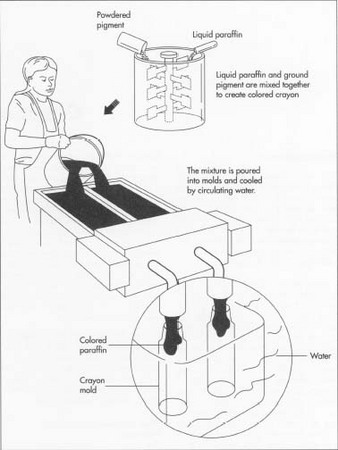

2 The paraffin "wets" the pigments as they are mixed, and

the mixing disperses the pigment uniformly. When the combination of

paraffin and color is fully blended, the batch is automatically pumped

out of the tubs into molds of the desired shape. Rotating blades inside

the mold prevent the formation of bubbles and lumps as the mixture

cools. The molds are cooled as water circulates around them. The color

of the crayon, and thus the type and quantity of pigment used, can

affect the time needed for cooling. Some colors will be ready for the

next step within four minutes, other colors can take as much as seven

minutes. The molds used for the crayons might hold as many as 2,400

forms.

Until recently, the paraffin-pigment mixtures were poured by hand from the tubs into a bucket and then into molds. Newer machinery now automates the process and pumps the mixture directly into the molds. In some large, older factories, both processes might be used.

Inspection and quality control

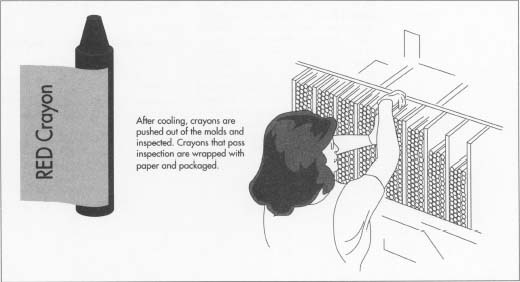

- 3 After cooling, the crayons are automatically pushed out of the molds and inspected. Inspectors examine each crayon for breaks and chips, as well as signs of bubbles in the cooled crayon, a condition that occurs if mixing has not been complete. Rejected crayons are returned to the tubs for remelting and recasting.

Wrapping and boxing

-

4 Crayons that have passed the quality control inspection are

automatically placed into racks where they are wrapped with paper

labels; most manufacturers use a double wrapping of paper to give the

crayons added strength. Crayons are automatically filled into boxes and

sent to wholesalers.

In the early days of crayon manufacture, an entire factory floor might be devoted to the production of a single color for a day or more. Following that color's molding, machines would be cleaned and a new color would be made. In today's factory, the demand for crayons is so huge, and the number of different colors so great (easily more than 100), that individual vats and molds are dedicated to only one or only a few colors, and the production lines run day and night.

Environmental Concerns

In the early 1990s, the Binney & Smith Company found great success marketing crayons with food scents that matched the colors and names of its crayons. Responding to concerns that young children would try to eat the crayons, the company determined to produce only crayons that smelled like non-edible objects such as flowers. All crayons sold in the U.S. are nontoxic. Although the ingestion of a large quantity of paraffin might result in a stomach ache, long-term effects are not likely to occur. U.S. law requires that all art materials sold in the U.S. be nontoxic. Most toxicology evaluations in the U.S. are performed under the auspices of the Arts and Crafts Materials Institute in Boston, Massachusetts. Each formula for any art product is submitted to the Institute and evaluated by a toxicologist. In addition to the out-and-out toxicity of an ingredient, a broad range of possible effects are also investigated. Testing is sometimes required, for example, to evaluate the interactions of individual ingredients within a single product or to determine whether a product will cause skin irritation. All materials must be evaluated at least every five years, and any change in the formula triggers a new evaluation.

Where To Learn More

Book

Pluckrose, Henry. Crayons. Franklin Watts, 1987.

Periodical

Baggerman, Lisa. "Creating Crayons." Art Materials Today, July-August 1994, pp. 54-62.

— Lawrence H. Berlow

Thank you.