Kayak

Background

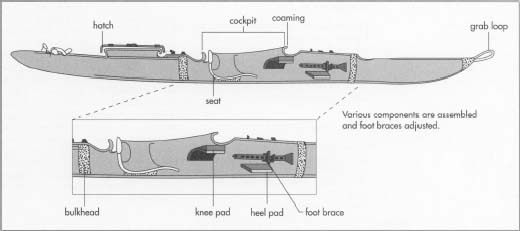

Kayaks have become an increasingly popular means of enjoying sporting and leisure boating activities. Kayaks resemble canoes in that both are long, narrow, lightweight paddle boats which are pointed at both ends. Like canoes, kayaks have a hull, which is the hollow bottom shell of the boat. However, several features distinguish kayaks from canoes. Kayaks are water displacement vessels, which means they float just below the surface, forcing the water to be pushed aside as they move. Canoes, on the other hand, float on the water's surface. Because the kayak sits lower in the water, it requires a deck. The deck is the semienclosed covering on the kayak's top. The purpose of the deck is to keep waves from washing over the edges of the boat and filling the hull with water. The cockpit is the opening placed in the center of the deck where the kayaker sits. The cockpit is surrounded by a raised lip called the coaming. Other kayak features include interior braces and bulkheads, interior flotation devices, and a cord called the grab loop attached to each end for towing and mooring. Some kayaks include elastic strapping or bungee cord s across the deck for carrying lightweight equipment. Other kayaks have waterproof hatches that give access to the forward and aft compartments for additional storage. Some sea kayaks have a rudder controlled by foot pedals to assist steering.

Kayaking is an excellent way to exercise and relax at the same time. A person sits upright in a kayak with legs extended to the front into the hollow hull. A double-bladed paddle is used for propulsion. Kayakers pull their crafts through the water by paddling with left and right strokes. A kayaker wears a life vest and, sometimes, a protective helmet. Waterproof spray skirts may also be worn. Spray skirts fit around the upper torso of the kayaker and attach to the deck around the cockpit opening to prevent water from splashing into the cockpit when navigating rough water.

The two most common uses of kayaks are racing and recreational boating. Racing kayaks are built for speed and maneuvering on river rapids, while recreational kayaks are built for comfort and longer distance paddling on oceans and lakes. Other design features distinguish racing from recreational kayaks. For example, racing hulls are narrow and v-shaped, whereas recreational hulls are more rounded. The number of seating areas for racing would typically be not more than two, while up to four seats might be provided for recreational purposes. The length, width, and weight would vary as well. Racing models tend to be shorter in length, 11-13 feet (3-4 m) long, and much lighter than recreational models. Some highly specialized racing kayaks weigh less than 25 pounds (11 kg). A typical recreational model will be 13-20 feet (4-6 m) long and may weigh as much as 75 pounds (34 kg). Most designs are no wider than 35 inches (89 cm) across.

History

The design and manufacture of kayaks have gone through many stages over the centuries, from primitive, handmade crafts used for survival to mass-produced sporting boats. Archeological evidence shows that kayaks were used at least 2,000 years ago by Eskimos for transportation, hunting, and

By A.D. 900, kayaks were being used in Europe. New designs in frames and coverings addressed the need to easily transport the kayak over land. One of these designs was a revolutionary collapsible kayak model called a foldboat which was invented in Germany in the 1800s. The foldboat used a rubberized canvas outer layer stretched over a folding tubular frame. The foldboat could be disassembled and carried in just two suitcases.

More recently, the primary use of kayaks has shifted from hunting and transportation to recreation and competitive sport. Kayaking for recreation began on rivers and lakes in the late 1800s. Sea kayaking was widely popularized when Percy Blanfold designed and built thousands of canvas-covered plywood and lumber kayaks in the 1950s and 1960s. Kayaking as a competitive sport began during the Summer Olympic Games in Germany in 1936 and has since gained international appeal.

Modern kayaks are built from covered wooden frames or from shells of fiberglass or plastic. Wooden kayaks most closely resemble the ancient Eskimo rib and cross frame construction. They are considered the classic design, and can be built from scratch in a very short time or assembled from kits. Durable marine or exterior-grade plywood is used for the frame. Waterproof glue and mechanical fasteners join the wooden pieces. Copper tacks or stainless steel staples are used for attaching the cotton canvas or cotton duck fabric to the frame. These coverings are treated and finished with airplane dope or exterior paint to waterproof and strengthen the fabric.

In the 1950s, fiberglass-reinforced resins

Polyethylene and the use of recycled plastics revolutionized kayak construction again in the early 1980s. The raw materials and manufacturing process for this latest advancement are described next.

Raw Materials

The idea that a kayak shell can be made from recycled plastics is very appealing to many environmentally-minded boaters. The primary ingredient of a plastic kayak is polyethylene. Polyethylene is a tough, waxy-textured material that is unaffected by water and many chemicals. It can be repeatedly softened by heating and hardened by cooling. These characteristics make it excellent for the manufacture of kayaks. Adequate supplies of polyethylene recycled from plastic beverage bottles are now available with sufficient durability and strength for use in making kayaks.

Polyethylene is also used to make the seats in a kayak. The flotation devices, bulk-heads, and padding for the kayaker's hips, knees, and heels are often made of a closedcell foam like Ethafoam. The rudder pedals or foot braces are usually made from a lightweight, corrosion-resistant metal like aluminum, as is the rudder itself. The grab loop may be nylon rope with a plastic or wooden toggle, or handle.

The Manufacturing

Process

The body of a polyethylene kayak is a long, hollow shell of uniform thickness made by a process called rotational molding. After the shell is made, the seat and other components are added in a manual assembly process. The shell may be molded in one piece, or it may be made from two separate pieces which are joined later. Rotational molding requires fairly rounded contours, so one-piece shells cannot have sharp intersections between surfaces. If the design requires a sharper intersection—such as between the hull and the deck, for example—then a two-piece shell is used. The process for making the two-piece shell is described here.

Loading the mold

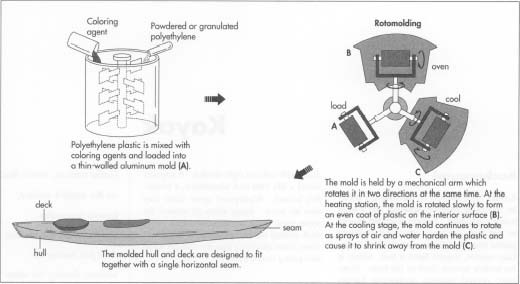

- 1 Measured amounts of powdered or granulated polyethylene plastic are mixed with coloring agents, and an exact amount is loaded into the bottom of a two-piece, thin-walled aluminum mold for either the hull or the deck. The mold is then closed and the two halves secured tightly.

Molding the hull or deck

- 2 The mold is held by a mechanical arm which can rotate the mold in two directions at the same time. The arm can also move, or index, the mold from one process station to another. After the mold is loaded, it is moved to the heating station where an oven heats it to 480-840°F (250-450°C). As the heat from the mold melts the plastic, the mold is slowly rotated in two directions. Gravitational force causes the melted plastic to flow to the front and rear and up the sides of the rotating mold, eventually covering the entire surface with a uniformly thick skin of plastic. Continued heating then fuses the plastic into a solid layer that attaches itself to the mold.

- 3 Next the mold is indexed to the cooling chamber. By continuing to rotate the mold and gradually cooling it with carefully directed sprays of air and then water, the kayak hull or deck further hardens and shrinks away from the mold. Repeated cycles of heating and cooling may be required to form the kayak properly. After the final cooling, the hull or deck is removed from the mold.

Assembling the shell

- 4 The hull and deck are designed so that they fit together at a single seam running horizontally along the length of the boat. Careful sealing ensures that the shell acts as a single structural unit. After sealing, a decorative strip can be added to conceal the seam. On some designs, a keel stiffener is bonded along the length of the shell to give it added strength.

Final assembly

- 5 Closed-cell foam flotation aids are inserted into each end of the kayak and held in place with adhesive. Some kayaks use inflatable flotation bags instead. These flotation aids keep the kayak level and floating on the surface should the craft capsize. If the kayak design uses bulkheads, then those pieces are bonded in place and sealed with a polyurethane sealant. The seat is either suspended from straps attached to the sides or supported by a piece of foam bonded to the inside of the bottom of the hull. Adjustable foot braces or rudder pedals are attached to the inside of the shell, forward of the cockpit, using non-corrosive metal fasteners. The hatch covers have waterproof gaskets installed before they are put in place and the grab loops are installed. Finally, a drain plug is inserted in a molded hole in the shell.

Shipping

- 6 Kayaks are relatively large, but light-weight. Packaging to protect the shell from abrasion is more important than providing a strong support. Traditional methods of preparing a kayak for shipping include shrink-wrapping in plastic or placing the kayak in a cardboard box. One environmentally sensitive approach uses heavy, tarp-like cloth bags.

Quality Control

Most of the quality control checks for a rotationally molded kayak are in the molding process. Maintaining the proper rotation speed and oven temperature are critical to producing shells with uniform thickness. Care is required during cooling to avoid warping the shell. The duration of the heating and cooling cycles, and the intervals between those stages, must also be controlled precisely.

The Future

Kayaking continues to grow as a recreational and competitive sport. Improved performance in competitive kayaking will depend on modern technology for new design and construction methods, and may result in the use of new materials. At the same time, many kayak enthusiasts will demand that these materials be environmentally benign, such as recycled plastics.

Where To Learn More

Books

Kulczycki, Chris. The Kayak Shop. McGraw Hill, 1993.

Freeman, Zu. Building a Jawbone Kayak. Tamal Vista Publications, 1989.

Periodicals

Noble, Peter, Michael Wadden, Timothy Bourke, David Williams, and Knut Nordbo. "An Introduction to Ethnotechnology for Naval Architects: Sea Kayak Design of Yesterday and Tomorrow." Marine Technology, October 1994, pp. 305-14.

Stark, Peter. "From Icy Northern Waters Came the Ancient Sea Kayak." Smithsonian, November 1992, pp. 150-62.

Wells, Edward 0. "Virtual Realities." Inc., August 1993, pp. 51-58.

Other

American Boat and Yacht Council, Inc. Publication H.29 (2). July 1, 1986.

— David N. Ford