Corn Syrup

Background

Corn syrup is one of several natural sweeteners derived from corn starch. It is used in a wide variety of food products including cookies, crackers, catsups, cereals, flavored yogurts, ice cream, preserved meats, canned fruits and vegetables, soups, beers, and many others. It is also used to provide an acceptable taste to sealable envelopes, stamps, and aspirins. One derivative of corn syrup is high fructose corn syrup, which is as sweet as sugar and is often used in soft drinks. Corn syrup may be shipped and used as a thick liquid or it may be dried to form a crystalline powder.

The use of corn as a food product dates to about 4000 B.C. when it was grown near what is now Oaxaca in Mexico. Because of its natural hardiness, corn was successfully cultivated by people in much of the Western Hemisphere. It was imported to Spain from the West Indies in about 1520 A.D. and soon became a popular food throughout Europe.

As the use of corn as a food product spread, various machines were developed to help process it. Water-powered mills, which had been used to grind wheat and other grains for thousands of years, were adapted to grind dried corn. By the early 1700s, a device to shell corn—remove the dried corn kernels from the cob—had been patented. The refining process used to separate corn starch from corn kernels is called the wet milling process. It was patented by Orlando Jones in 1841, and Thomas Kingsford established the first commercial wet milling plant in the United States in 1842.

The process for converting starches into sugars was first developed in Japan in the 800s using arrowroot. In 1811, the Russian chemist G.S.C. Kirchoff rediscovered this process when he heated potato starch in a weak solution of sulfuric acid to produce several starch-derived sweeteners, including dextrose. In the United States, this acid conversion method was adapted to corn starch in the mid-1800s and the first corn sweeteners were produced in a plant in Buffalo, New York, in 1866. This process remained the principal source of corn syrup until 1967, when the enzyme conversion method for producing high fructose corn syrup was commercialized. At first, this was a batch process requiring several days. In 1972, a continuous enzyme conversion process was developed that reduced the time to several minutes or hours.

Today, corn syrups are an important part of many products. In 1996, there were 28 corn-refining plants in the United States that processed a total of about 72 billion lb (33 billion kg) of corn. Of that amount, about 25 billion lb (11.4 billion kg) were converted into corn syrups and other corn sweeteners. These corn-based products supplied more than 55% of the nutritive sweetener market in the United States.

Raw Materials

There are several thousand varieties of corn, but the variety known as yellow #2 dent corn is the primary source of corn syrup. It is a common variety grown in the Midwestern portion of the United States and elsewhere in the world. It belongs to a family of corn that derive their name from the small dent in the end of every kernel.

Other materials used during the process of converting corn to corn syrup include sulfur

The Manufacturing

Process

Corn syrup is produced in processing plants known as wet corn mills. In addition to corn syrup, these mills produce many other corn products including corn oil, corn starch, dextrose, soap stock, animal feed, and several chemicals used in other industrial processes.

Separating corn starch from corn

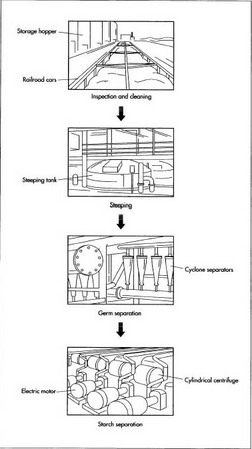

- 1 Dried, shelled corn kernels are transported to the mill in trucks, railcars, or barges. The corn is unloaded into a storage pit where it is weighed and sampled.

- 2 The kernels are taken from the pit on conveyors and are passed over a set of vibrating screens or perforated metal grates to remove any sticks, husks, stones, and pieces of cob. A controlled blast of air blows away any chaff and dust, while electromagnets capture any nails, screws, or bits of metal that may have fallen in among the kernels during harvesting, shelling, or shipping.

- 3 The cleaned kernels are placed in a series of large stainless steel tanks called steep tanks. Each tank holds about 168,000 lb (76,000 kg) of kernels. Warm water with a small amount of sulfur dioxide is circulated through the tanks. The sulfur dioxide reacts with the water to form a weak sulfurous acid solution. This process continues for about 20-40 hours and is used to soften the kernels and make it easier to separate the starch.

- 4 The softened kernels are passed through coarse grinding mills to remove the inner portion of the kernel, called the germ, which contains most of the corn oil. Each mill has one stationary and one rotating disk. The clearance between the two disks is adjusted to tear the kernel apart without crushing the germ.

- 5 The resulting pulp is transferred to a set of cyclone separators called germ separators or hydroclones. The germs, which are less dense than the other parts of the kernel, are spun out of the pulp by centrifugal force. The germs are then pumped onto a series of screens and washed several times to remove any remaining starch. The cleaned germs are heated and pressed to extract the corn oil for further processing into food products and soap stock.

- 6 The remaining material from the germ separators is a slurry composed of starch, protein, and fiber. This slurry passes through another set of mills to tear the starch lose from the fiber. The fiber is then trapped on a set of washing screens and is dried to become animal feed or corn bran fiber for use in cereals.

- 7 The starch and protein mixture, called mill starch, is pumped into a set of centrifugal separators that spin the mixture at high speeds. Because of a difference in specific gravity between the two materials, the heavier starch can be separated from the lighter protein, which is called the gluten. The gluten is dried and sold as animal feed.

- 8 The starch is diluted with water before being washed and filtered 8-14 times to remove any remaining protein. It is then rediluted and run through a second set of centrifugal separators. The resulting starch is more than 99.5% pure. Some of this corn starch is dried and packaged for use in food products, building materials, or to produce various chemicals. The rest of it, usually the majority, is converted into corn sweeteners including corn syrup.

Converting corn starch into corn syrup

- 9 Corn starch is converted into ordinary corn syrup through a process called acid hydrolysis. In this process, the wet starch is mixed with a weak solution of hydrochloric acid and is heated under pressure. The hydrochloric acid and heat break down the starch molecules and convert them into a sugar. The hydrolysis can be interrupted at different key points to produce corn syrups of varying sweetness. The longer the process is allowed to proceed, the sweeter the resulting syrup.

- 10 This syrup is then filtered or otherwise clarified to remove any objectionable flavor or color. It is further refined and evaporated to reduce the amount of water.

- 11 To produce a corn syrup powder, also called corn syrup solids, the liquid corn syrup is passed through a drum or spray dryer to remove 97% of the water. This produces a crystalline corn syrup powder.

Converting corn syrup into high fructose corn syrup

- 12 Ordinary corn syrup contains dextrose sugar which is about three-quarters as sweet as the sucrose sugar in cane or beet sugar. In many sweetener applications this is an advantage because it does not overpower the other flavors in the food. Howev-. er, in some applications, such as soft drinks, a sweeter taste is desired. To improve the sweetness of ordinary corn syrup, it undergoes a further process called enzyme conversion. In this process, the dextrose sugars in the syrup are converted into sweeter fructose sugars by the action of an enzyme in a series of steps under carefully controlled temperatures, pressures, and acidity. This produces a high fructose corn syrup with a 42% fructose content. It is used in canned fruits and condiments.

- 13 To produce corn syrups with a fructose level above 50%, syrupsthe 42% fructose syrup is passed through a series of fractionation columns, which separate and hold the fructose content. The separated portion is about 80-90% fructose and is flushed from the columns with deionized water. A portion of this is retained and sold for use in "light" foods where only a small amount of liquid sweetener is needed. The remainder is blended with other 42% fructose syrup to produce a 55% fructose syrup, which is used in soft drinks, ice cream, and frozen desserts.

- 14 Powdered high fructose corn syrups can be produced by evaporating the water from the syrup and then encapsulating the powder grains to prevent them from reabsorbing moisture. Pure fructose crystals may be obtained by further processing the 80-90% fructose syrup. It is used in cake mixes and other food products where a highly concentrated, dry sweetener is desired.

Quality Control

Corn syrup is primarily used as a food product. In the United States, its production and use falls under the control of the federal Food and Drug Administration (FDA), which sets rigid quality standards. The corn refiners, working through the Corn Refiners Association, have developed comprehensive analytical procedures for testing the properties of corn products, including corn syrup. Some of the important properties of corn syrup are dextrose or fructose content, carbohydrate composition, solids content, sweetness, solubility, viscosity, and acidity. In addition to monitoring the materials and processes used to make corn syrup, manufacturers also take frequent samples of the finished product for analysis.

The Future

Because of the ready supply of corn in the United States, it is expected that corn syrup and other corn sweeteners will continue to be used extensively in food products.

Corn is also expected to be a source of many other products in the future. Ethanol can be derived from corn and offers a cleaner-burning fuel than gasoline for use in motor vehicles. Corn starch can be used as a raw material to replace petroleum in the production of chemicals and plastics. Corn products may also find applications in the production of drugs and antibiotics.

Where to Learn More

Books

Considine, Douglas M., ed. Foods and Food Production Encyclopedia. Van Nostrand Reinhold, 1982.

Hui, Y.H., ed. Encyclopedia of Food Science and Technology. John Wiley and Sons, Inc., 1992.

Matz, Samuel A. The Chemistry and Technology of Cereals as Food and Feed. Pan-Tech International, 1991.

McGraw-Hill Encyclopedia of Science and Technology. McGraw-Hill, 1997.

Other

Corn Refiners Association. http://www.corn.org .

"Corn Refining: The Process, The Products." Corn Refiners Association Inc., 1992.

"Nutritive Sweeteners From Corn." Corn Refiners Association Inc., 1993.

"Tapping the Treasure." Corn Refiners Association Inc., 1997.

— Chris Cavette