Globe

Background

Globes fall into two broad categories: terrestrial and celestial. Terrestrial globes are spherical maps of the world, and celestial globes use the earth as an imaginary center of the universe to map the stars in spherical form. A globe is the only "true" map of the world because there is no distortion in relationships of areas, directions, or distances. The actual flattening of the true earth at its poles and "fattening" around the equator are such small, real distortions that they don't appear at the scale of most globes. The sphere constituting the globe is mounted on an axle and stand so it can be rotated like the earth. The axle's tilt (23.5°) is the same as Earth's rotation on its axis (relative to the plane in which it orbits the Sun).

There are many types of globes within the classification of terrestrial globes. A physical globe depicts Earth as the astronauts see it (except that they also see the intervening clouds and the shadows cast by the sun). Although physical globes emphasize natural land features (sometimes showing them in relief), the features of the bottom of the sea can also be shown. A political globe shows the nations of the world in a variety of colors as well as other features of civilization like locations of cities. Varieties of celestial globes extend to globes of the planets and the moon. Thanks to satellite imagery and other technological advances, the physical features of the world are now available in globe form on CD-ROM as the digital globe.

History

The ancient Greeks never gave credence to "flat earth" theories. They knew the world was spherical and made the first globes to depict their understanding of it. A Greek named Crates is credited with making the first globe in about 150 B.C. Our ancient ancestors were quick to adapt the principle of the globe to mapping the skies. The Romans made a celestial globe called the Farnese globe in 25 A.D. Because they used local marble for this feat, the globe survives today.

German geographer Martin Behaim made the earliest terrestrial globe that has survived. Behaim's accomplishment was timely; he made his globe in 1492, and Christopher Columbus was almost certainly aware of it and strengthened by it in his conviction to sail West to find the Orient. Today's globes would not be the same without the Flemish geographer Gerhard Kremer who is better known by the Latin form of his name, Gerardus Mercator. Mercator lived from 1512-1594 and was also a cartographer, mathematician, astronomer, and engraver. He is best known for having developed the type of map, now called a Mercator projection, in which all the meridians and longitudinal lines are parallel and the lines of latitude intersect these at right angles and are also parallel to each other. The Mercator projection simplified map reading; for instance, a navigator can plot a ship's course between any two points in a straight line and follow that course without changing compass direction. Mercator also widely influenced all other aspects of mapmaking; the world atlas is also his invention. He made Louvain, Belgium, the center of the world of cartography and scientific instruments; and, there, he and Myrica Frisius constructed terrestrial and celestial globes in 1535-1537.

Raw Materials

In the past, globes were generally solid and made of a variety of materials including glass, marble, wood, and metal. Hollow globes, including those made in Mercator's day, were produced from thin metal sheets including copper. Today, globes are almost always hollow and can be made of any material that is both strong and lightweight. Cardboard, plastic, or metal can be used. A three-dimensional jigsaw puzzle with paper pieces backed with foam rubber is manufactured for puzzle fanatics, plastic globes with snap-on continents and other features are learning tools for children, decorative globes of Waterford crystal can ornament desk tops, and inflatable globes (both terrestrial and celestial) are useful tools and toys.

The George F. Cram Company and Replogle Globes Inc. are the only two manufacturers of traditional globes in the United States. The George F. Cram Company has made maps since 1867 and globes since 1929. The company's manufacturing processes for producing the two basic types of globe remain largely unchanged in 70 years. One type is made of fiberboard or cardboard, and the illuminated globe is made of plastic that will withstand the heat from a light bulb that is placed inside the sphere to light it from the inside out. Recycled cardboard is used for the cardboard globes. Injection molding plastic is also used to partially fill the plastic globe. Specialty manufacturers produce all other parts for the globe. These include tape required to join the two globe hemispheres ("Equator tape"); the axis, stand, base, or other mounting; and electrical wiring and the bulb socket for the illuminated version.

Design

Globes are made in two standard sizes. The 12in (30.5 cm) diameter globe (roughly the size of a basketball) is the most popular globe sold to schools and retailers, and the second most popular size is 16 in (40.6 cm) in diameter. Of all the globes sold, 80% of them are 12 in (30.5 cm) globes. Apart from distinctions like terrestrial, political, relief, celestial, etc., globes are made in a variety of color schemes because they are made as ornamental as well as informative objects to decorate homes and offices. Interestingly, children prefer globes with blue oceans, while adults like non-blue globes, of which the antique or off-white color is favored.

Globe manufacturers decide on new product lines based on constant input from the marketplace. Teachers may be the most important source of new globe concepts because they request changes in globes as the curriculum is modified. Globe makers also watch design and fashion trends because many globes are spontaneous purchases made because of appearance, and purchasers expect ornamental globes to be available in designs to match their decors. The globes themselves don't necessarily change for reasons of fashion, but stands and display pedestals do. Obvious choices include selections in dark and light wood; current trends toward Southwestern-style decor and wrought iron work have made globes mounted in these styles popular.

Manufacturers also produce new globes as changes in our world occur. Each manufacturer's research staff monitors changes in data that may require artwork adjustments. Physical globes tend to change little simply because geologic processes are slow and small and don't appear at the scale of most globes (660 miles to the inch on a 12-inch globe). Political changes occur more rapidly but are still not frequent. In the past five years, only three political changes have affected world globes, with two in Africa and one in Europe. By making computerized changes to the artwork printed on the globe, corrections can be made almost instantaneously. Sources for political changes in the world include the Office of Geographic Names (part of the U.S. Department of the Interior), the State Department, and the embassies of various governments. Globe-makers in the United States do not change political names until the State Department has officially recognized that a name change has occurred. For physical changes, the embassies are again sources, as is the Library of Congress. In the United States, the respective states are sources for information about changes within their boundaries. For example, the State of Louisiana provides data about the changing configuration of the Mississippi River Delta.

The Manufacturing

Process

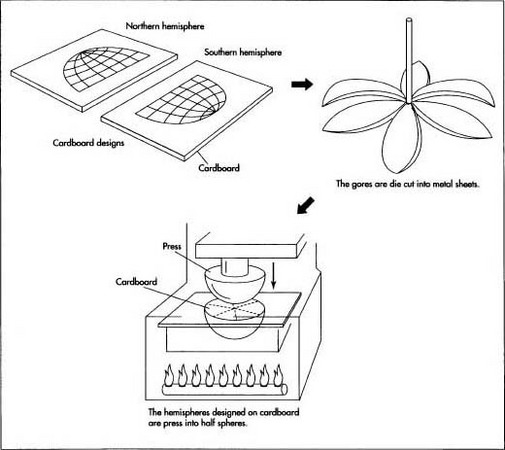

- The world is flat when the process of making a globe begins. Highly detailed and informative artwork prepared by a staff of researchers and cartographers is printed on sheets of cardboard. The Southern Hemisphere is printed on one sheet, and the Northern Hemisphere is reproduced on a second sheet of cardboard.

- Gores, or tapering triangles, are then diecut into the printed sheets by a specialized machine; the half globe with cut gores looks like a pinwheel or a banana peel with a pole at the center and the parts of the peel forming segments of the world.

- The artwork is designed and the gores are located in such a way that adjacent segments will match correctly when joined.

-

The cardboard hemispheres are then subjected to heat and pressure in a

forming press to shape them into half spheres. The forming press works

much like a curling iron and heats each hemisphere to about 300° F

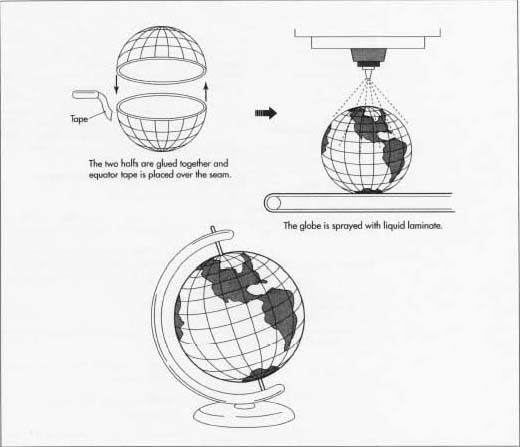

(148.9° C) for 90 seconds. In the joining process, the two halves

are glued together to produce the round ball, and Equator tape is placed

to cover the seam.

The two halves are glued together to form a globe, which is then laminated for durability.

The two halves are glued together to form a globe, which is then laminated for durability. - The completed ball is then sprayed with a liquid laminate to make it durable, fingerprint-proof, and glossily attractive.

- After manufacture of the spheres is completed, they are fitted to any of the wide variety of mountings from inexpensive plastic to brass. The illuminated globes are equipped with light bulbs and electrical sockets, switches, and cords. The completed globes are packaged for sale or shipment.

Illuminated globes

Illuminated globes are made in a very similar manner except that the basic material is different. Artwork is printed on flat sheets of plastic substrate, this time with both hemispheres on the same sheet. The substrate is vacuum-formed into hemispheres by a one-of-a-kind machine that heats the plastic to thousands of degrees and sucks it into shape by applying a vacuum to the pliable plastic. The formed hemispheres are shipped offsite to an injection-molding factory where plastic is injected into them to harden the product. Space remains inside for the illumination source, and a hole is cut in Antarctica so the light bulb and socket can be inserted later. The two hemispheres are glued and taped together. The finished globe is so tough that it can actually be dribbled like a basketball on a concrete floor for five or six dribbles before it will break. The main advantages of owning an illuminated globe are that it is easier to read and it is more durable. The disadvantage is that cardboard used to make globes can be formed into a greater variety of products, including globes with topographic relief, and the vacuum-forming process for making the illuminated globes can only produce a smooth surface.

Quality Control

Technicians who manufacture globes are ISO 9000 certified and trained to ensure that each production step is consistent with established standards. Each production step is also a quality station. The technicians are responsible for rejecting products for any flaws, not just those occurring during their particular step of the process.

Byproducts/Waste

There are no byproducts from globe manufacture, although globe-makers often produce maps and related items. Waste is very limited. When the fiberboard is die-cut, the triangles that are removed are scrap; however, the cardboard is again recycled.

The Future

The globe's future is assured as a method of better understanding the changing face of the world we live in. Like manufacturers of many products, globe-makers face the challenge of identifying new ways of catching the public's fancy. Globes are often given as gifts to be used in specific settings (that is, by a student of a particular age or for business reference when the globe's mounting should match the office decor), and they must also be easy to use. Globes illustrate a tremendous amount of information, and manuals that are purchased with them need to be useful tools. The newest types of globes are becoming interactive and speak the names of countries, as they are touched. They are also designed to present certain information for users in the "global village"; time zone information, for example, can help corporate leaders communicate with their international counterparts in a timely manner. One of the latest and most significant advances in globe making has already occurred, thanks to digital technology. The development and manufacture of the digital globe is described in a companion article.

Where to Learn More

Periodicals

Mickle, Linda, ed. Map Report. Kankakee, IL: International Map Trade Association.

Sell, Colleen T., ed. Mercator's World: The Magazine of Maps, Exploration & Discovery. Eugene, OR: Aster Publishing Company.

Other

Captain's Globes. http://www.finestl.com/globes/ .

George F. Cram Company. http://www.georgefcram.com .

International Map Trade Association. http://www.maptrade.com .

Mercator's World. http://www.mercatormag.com .

Motion Globes. http://www.motionglobes.com .

National Geographic Society. http://www.nationalgeographic.com .

— Gillian S. Holmes

Comment about this article, ask questions, or add new information about this topic: