Child Safety Seat

Background

In the United States, more than 2,000 children under 14 years of age die each year in vehicle crashes. Not only are vehicle crashes the leading killers of children, in 1997 they also injured nearly 320,000 youngsters. Most of the fatalities happen because the children aren't secured in specially designed car seats. Instead, they are strapped in the wrong kinds of seats, such as adult seats that neither position the children's bodies properly nor cushion them against impact, or they aren't wearing any restraints at all. Children aged four to 14 are least likely to be restrained properly.

Most of the 50 states require that children under the age of four be secured in child safety seats or seat belts. Many states also mandate booster seats (or seat belts) for kids between four and 14 depending on their age, weight, and height. Up to 95% of the safety seats that are installed in vehicles may not be the right seat for the child, may be hooked so loosely with an incompatible belt in the car that the seat rotates or pitches forward, or may have harnesses incorrectly fastened in some way. Child seats are also often incorrectly placed rear-facing in front of air bags. In 1997, six out of 10 children who were killed in vehicle crashes were unbelted. Enormous energies and talents have produced child safety seats that, when used properly, have vastly improved the likelihood that a child can survive a serious vehicle crash without injury.

History

Car seats for children have been manufactured since 1933. The Bunny Bear Company made several designs of children's car seats, but their purpose was not to protect the child in the event of an accident. Instead, these seats confined the children, raised them above the level of the passenger seat, and made them more visible to adults from the front seat. The true safety seat for children was invented in England by Jean Ames in 1962. The Ames design had straps that held the padded seat against the rear passenger seat. Within the seat, the child was restrained by a Y-shaped harness that slipped over its head and both shoulders and fastened between the legs. Other designs to accommodate growing children followed quickly over the next several years.

From 1956-1970, lap-type seat belts were developed and became standard equipment for adults. Even though crash-test results proved that seat belts saved lives, in the 1960s seat belts were met with resistance. In 1966, Congress passed the Twin Highway Acts that empowered the Department of Transportation (DOT) to set standards for vehicle design; the separate states have the authority to enforce driver laws, which vary among the states. Shoulder harnesses, self-applying belts, and front- and side-impact air bags increased the level of protection for adults; these types of safety equipment became available from 1966-1995. During this period, child safety seats grew to include rear-facing seats for infants under 22 lb (10 kg), convertible seats that start as rear-facing infant seats and convert to face forward for toddlers weighing less than 40 lb (18.2 kgs), and booster seats that elevate a growing child weighing between 30-70 lb (13.6-31.8 kg) so the car's seat belt can be fastened around child and booster seat. Child safety seats are in the news almost daily, yet more than 30 years after their development, many of these news items focus on the inconvenience of the seats rather than the lives they save.

Raw Materials

The child safety seat is made of polypropylene, a tough plastic that flexes under pressure and doesn't crack easily the way some other plastics do. The plastic is transported to the factory in the form of pebble-sized pellets; a major car seat maker receives train cars full of the pellets for its production. Coloring, which varies among the seat models, is added to the plastic.

Several of the smaller components like buckle latch plates, harness adjusters, locking clips, and the buckles themselves are usually made by specialty manufacturers. Indiana Mills makes buckle and adjustment mechanisms for almost all American manufacturers of child safety seats.

Fabrics and vinyls are used to make safety seat covers and harnesses. Both covers and harnesses have to be able to withstand flammability tests, but they also have to be washable. Only mild soap and water can be used because detergents or chemicals break down the flame resistant fabric treatments. The thread that sews these materials together has to meet the same requirements. Color, durability, and fashion are other considerations in selecting the cover fabrics. The harnesses meet the same strength requirements as those for adult seat belts.

The seats are padded with foam. Types of foams are heavily regulated to meet standards for flame resistance and energy absorption. Pads and covers are sewn by the child safety seat manufacturer or by outside suppliers.

Printed paper components are among the most important. Labels are designed by the manufacturer in accordance with Federal standards. Locations of labels on the device, precise wording, and paper that withstands tears (so missing information is evident) are among the specifications. Instructions are also prepared to meet exacting requirements, and the child safety seat must include permanent storage for the instructions. Physical printing of labels and instructions is usually done by printers subcontracted by car seat manufacturers.

Assembly also includes small parts such as rivets and fabric fasteners. These parts are all manufactured and supplied by specialty firms.

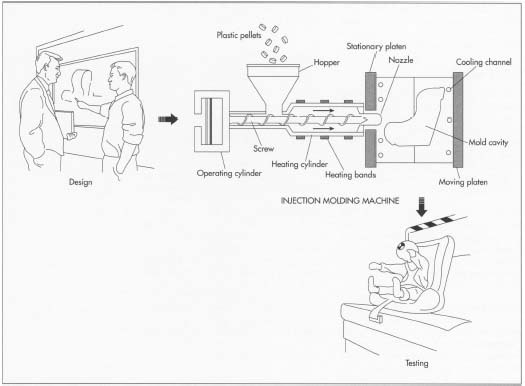

Design

A wide variety of design issues must be considered for each type of child safety seat. The four most important design issues are safety (including meeting government regulations), ease of use (and this includes the child's comfort), style or appearance, and manufacturing feasibility. A strict set of government regulations (Federal Motor Vehicle Safety Standard [FMVSS] 213) establishes the seat back height, buckle release pressure, type of impact-absorbing foam, the wording of some labels, and much more. The seat also must be able to withstand a crash test of either two cars each traveling at 30 mph (48 kph) hitting each other head-on or a car crashing into a parked car at 60 mph (96 kph). After the crash test, the seat must still meet certain performance criteria like buckle release pressure.

Two major changes in regulations are radically altering safety seat design. The distance the child's head is allowed to move forward in a crash (called the "head excursion") has been reduced from 32 in (81 cm) to 28.5 in (72 cm). To meet this requirement, most seats will probably need a tether or strap on the top of the child seat that will be anchored behind the car seat. The shells of many designs of child safety seats will also have to be reinforced to meet this standard (and vehicles will also require anchor points for the tethers).

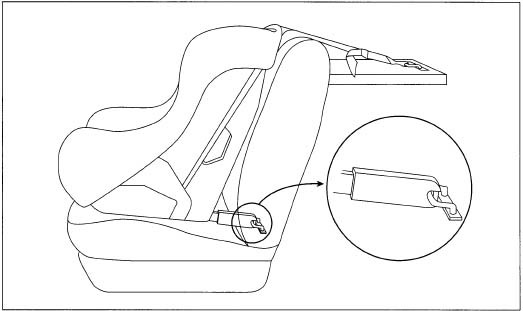

Another new regulation becomes effective in 2002. Special anchor attachments will be added to safety seats that will secure them to new anchors in the vehicles and reduce the problem of using the safety belt to secure the child seat to the car seat. This "universal attachment system" uses attachment belts in different locations on the safety seat than current designs, so the safety seat will require considerable redesigning and strengthening.

The child's comfort and ease of use of the seat are much more subjective. Charts of average child sizes within particular age and weight ranges help designers fit the seat to the child and make it comfortable. To understand the parents' perspective on using the seats, manufacturers consult with focus groups; analyze sales trends as indicators of ease of operations, ease of inserting and removing infants, and popularity of features such as pillows and seat protectors; and listen to consumer feedback through vehicles like consumer e-mail.

Consumer opinion also includes fashion and appearance of the safety seats. Purchasers prefer infant seats with lighter colors of fabrics and child-like patterns. Seats for older children tend to match trends in vehicle design, including darker colors and more sophisticated patterns that are coordinated with vehicle interiors.

Design must also consider constructability. The method of molding the seat, the materials used, the method of assembly, and other characteristics may simply not be compatible with other desirable design features. The process of design conception through production startup takes from one to three years, depending on the complexity of the design. Design time is expected to be slower as the first seats with the new anchorage system are designed, constructed, and tested, although it will quickly resume speed as designers become accustomed to working with the new system.

The Manufacturing

Process

-

Manufacture of the child safety seat begins with molding the shell. The

plastic pellets are melted and injection-molded into forms for the

shell. The molded forms are

trimmed and cleaned. As soon as they are cooled, they are delivered to the assembly line.

Effective in 2002, the "universal attachment system" will secure child safety seats to anchors located in every automobile. The switch from seat belt attachment to an anchoring system will reduce the problems that occur with the use of seat belts.

Effective in 2002, the "universal attachment system" will secure child safety seats to anchors located in every automobile. The switch from seat belt attachment to an anchoring system will reduce the problems that occur with the use of seat belts. - The parts made by outside suppliers are distributed to work stations along the assembly line. These include the foam padding, cover, harness, buckle, labels, and instruction. Usually, the assembly line does not use a conveyor belt; workers simply complete their portion of the work and hand the seat to the next person along the line. This enables personnel to work at their own pace and check their own work on the product.

- The padded cover is placed on the shell and attached. The buckle assembly is secured to the shell, and the harness is threaded through the buckle, adjuster, and harness retainer.

- The labels are secured on the safety seat, and instructions are packed in the storage compartment that is a mandatory part of design of the seat.

- If the product is also to be sold with point-of-purchase pieces (hang tags) related to marketing or advertising, these are added before the seats are packed in cartons. Before packing, some seats may be selected for quality and performance reviews including crash testing.

- In the packing department, the seats are packed in cartons that carry information and designs developed by marketing and advertising. Generally, the cartons are stacked and wrapped in plastic so the cartons are kept clean until they are ordered and shipped. The wrapped batches of cartons are stored on pallets and moved by forklift. Some are loaded directly into trucks for shipment or taken to inventory.

Quality Control

Manufacturers maintain a quality control department and an established inspection system. At one manufacturer, for example, every person on the assembly line is expected and encouraged to report errors, and all seats are inspected on the line for visually detectable problems. Individual parts are typically compared to masters for correctness, and each product has a bill of materials that lists the part numbers of every part in the product. Product managers may also pull products off the line for review.

Crash testing is also done to test child safety seat models. Cosco, Inc., is the only domestic car seat manufacturer with its own dynamic crash test sled for assuring quality and performance. Quality can be aided by the sharing of safety-related information among manufacturers. The Juvenile Products Manufacturers' Association car seat committee assists with distributing information and collaborating on labeling and education programs. Industry representatives participate on committees, such as the Blue Ribbon Panel and the Society of Automotive Engineering (SAE), that develop recommendations for car seat makers, vehicle manufacturers, and government agencies.

Byproducts/Waste

Manufacturers usually produce several lines of child safety seats. For example, Cosco makes a car bed/car seat, three kinds of infant-only seats, four kinds of convertible seats, a line with three car seats in one to adapt to a growing child, a high backed booster seat, a travel vest, and an auto booster.

Shells that are rejected by quality control or that have been used in crash testing are reground and combined with new plastic for remolding. Only a very small percentage of reground plastic is allowed in remoldings. Covers may not fit or may have been sewn incorrectly; if so, they are returned to the supplier and resewn. Metal parts like clips that may not have been plated properly can be replated or recycled. Other parts like incorrectly made buckles are discarded. Very little waste results.

The assembly process is also environmentally and worker friendly. Mold operators wear protective gloves. Power screwdrivers and riveters are the only other equipment used in the assembly.

The Future

Computer systems like Cosco's Tattle Tales system will allow car seats to give verbal warnings to caregivers if the child is climbing out of the car seat or the buckle is unlocked, for example. These systems perform several checks per second, and, when the driver hears the warning, the vehicle can be stopped and the child can be resecured in the seat.

The universal attachment system (mandatory by 2002) will standardize the way in which child safety seats are attached in all vehicles. Air bags remain a concern, but "smart" air bags are in design that will recognize the sizes of vehicle occupants and whether they are correctly seated or are out of position. Ultimately, automated highway systems will reduce opportunities for driver error and other crash-causing circumstances on major highways, but seat belts and child safety seats are likely to be necessary.

Where to Learn More

Periodicals

"Crash-test favorites." Daily Review (Hayward, California), 9 May 1999, p. BAL-2.

Fix, Janet L. "U.S. to promote safe use of child safety seats, seat belts." Knight-Ridder/Tribune News Service, 18 November 1998.

"How to keep traveling children safe." Childhood Education (Spring 1997): 174+.

Shelness, Annemarie and Charles, Seymour. "Children as Passengers in Automobiles: The Neglected Minority on the Nation's Highways." Pediatrics Vol. 56, 1975, pp. 271-284.

Stevens, Liz. "Car seats the bane of every parent's existence." Daily Review (Hayward, California), 9 May 1999, p. BAL-2.

Other

American Academy of Pediatrics (AAP). http://www.aap.org/family/mncrseat.htm/ .

Cosco, Inc. http://www.coscoinc.com/ .

Family Health and Safety. http://www.saferidenews.com/ .

National Highway Traffic Safety Association. http://www.nhtsa.dot.gov/people/injury/childps/ .

National Safe Kids Campaign Online. http://www.safekids.org/ .

Safety Belt Safe U.S.A. http://www.carseat.org/ .

Safe Within. http://safewithin.com/child-safe/child.seat.cgi/ .

Society of Automotive Engineers. http://www.sae.org/ .

— Gillian S. Holmes

Comment about this article, ask questions, or add new information about this topic: