Hourglass

Background

Before the invention of mechanical clocks, timepieces used the sun's motion or simple measurement devices to track time. The sundial may be the best known ancient keeper of time, and it is still manufactured as a popular garden accessory—but for its visual interest, not for practical time measurement. Stonehenge, the giant monument built of upright stones on the Salisbury Plain of Wiltshire, England, may have been used as a sundial and for other time and calendar purposes. Sundials have obvious disadvantages; they can't be used indoors, at night, or on cloudy days.

Other simple measurement devices were used to mark the duration of time. Four basic types could be used indoors and regardless of the weather or time of day. The candle clock is a candle with lines drawn around it to mark units of time, usually hours. By observing how much of the length of a candle burned in one hour, a candle made of the same material was marked with lines showing one-hour intervals. An eight-hour candle showed that four hours had passed when it had burned down beyond four marks. The clock candle had the disadvantages that any changes in the wick or wax would alter burning properties, and it was highly subject to drafts. The Chinese also used a kind of candle clock with threads used to mark the time intervals. As the candle burned, the threads with metal balls on their ends fell so those in the room could hear the passage of the hours as the balls pinged on the tray holding the candle.

The oil lamp clock that was used through the eighteenth century was a variation and improvement on the candle clock. The oil lamp clock had divisions marked on a metal mount that encircled the glass reservoir containing the oil. As the level of oil fell in the reservoir, the passage of time was read from the markings on the mount. Like the candle clock, the oil lamp clock also provided light, but it was less prone to inaccuracies in materials or those caused by drafty rooms.

Water clocks were also used to mark the passage of time by allowing water to drip from one container into another. The marks of the sun's motion were made on the first container, and, as water dripped out of it and into another basin, the drop in water level showed the passage of the hours. The second container was not always used to collect and recycle the water; some water clocks simply allowed the water to drip on the ground. When the eight-hour water clock was empty, eight hours had passed. The water clock is also known as the clepsydra.

History

Hourglasses (also called sand glasses and sand clocks) may have been used by the ancient Greeks and Romans, but history can only document the fact that both cultures had the technology to make the glass. The first claims to sand glasses are credited to the Greeks in the third century B.C. History also suggests sand clocks were used in the Senate of ancient Rome to time speeches, and the hourglasses got smaller and smaller, possibly as an indication of the quality of the political speeches.

The hourglass first appeared in Europe in the eighth century, and may have been made by Luitprand, a monk at the cathedral in Chartres, France. By the early fourteenth century, the sand glass was used commonly in Italy. It appears to have been widely used throughout Western Europe from that time through 1500. The hourglass or sand clock follows exactly the same principle as the clepsydra. Two globes (also called phials or ampules) of glass are connected by a narrow throat so that sand (with relatively uniform grain size) flows from the upper globe to the lower. Hourglasses were made in different sizes based on pre-tested measurements of sand flow in different sizes of globes. A housing or frame that enclosed the globes could be fitted to the two globes to form a top and bottom for the hourglass and was used to invert the hourglass and start the flow of sand again. Some hourglasses or sets of hourglasses were set in a pivoted mount so they could be turned easily.

The earliest writings referring to sand glasses are from 1345 when Thomas de Stetsham, a clerk on a ship called La George in the service of King Edward III (1312-1377) of England, ordered 16 hourglasses. In 1380, following the death of King Charles V (1337-1380) of France, an inventory of his possessions included a "large sea clock … in a large wooden brass-bound case."

John Harrison and his brother James were introduced to clock repair by their father, Henry. At the time, clock making, or horology, was undergoing a developmental revolution. Mechanical clocks had existed since the fourteenth century, but had remained rather primitive in their operation until Christiaan Huygens invented the weight-and-pendulum clock in 1656. One limitation was that they were totally dependent upon the earth's gravity for their operation. This meant that they could not keep accurate time at sea, and could not be adapted for portability. Even moving them across a room would require adjustment.

The Harrison brothers set to work on developing a marine chronometer in 1728. The motivating factor was money. In 1714, the English Admiralty set up an award of £20,000 for anyone who could provide mariners with a reliable clock that, when used with celestial sightings, could keep them informed of their longitude at sea. Mariners had to rely heavily on dead reckoning to find their way, often leading to tragic results.

The Harrison strategy was to design an instrument that was not only internally accurate but also externally stable. The Harrisons made several models of marine chronometers. The fourth model proved to be the most successful. On a nine-week voyage from England to Jamaica in 1761, the device had only a five-second error.

The Board of Longitude, apparently miffed that a common artisan had achieved the coveted goal, reluctantly gave up only half of the prize. John, minus his brother, refused to accept only half of the reward and persisted until the other half was relinquished.

The Board subjected his invention to undue scrutiny and required him to design a fifth model. This time, Harrison outdid himself by designing a compact timepiece that resembled a modern day pocket watch. It was far more convenient than the previous models, which were heavy and bulky. The Board still refused to capitulate. Finally, only a personal appeal to King George III and the King's intervention could set things right, and Harrison received the full reward in 1773 at age seventy-nine. Harrison lived only three more years.

These two early associations of sand clocks with the sea show how navigation had become a time-dependent science. Compasses and charts, developed in the eleventh and twelfth centuries, helped navigators determine bearings and direction, but time measurement was essential to estimating distance traveled. The sand glass may have been invented —or perfected—for use at sea where equal units of time were measured to estimate distance; by contrast, on land, unequal time measurements were more important because activities depended on the length of day.

The great advances in maritime science occurred in the twelfth century with the development of the magnetic compass in Amalfi, Italy. Other Italian port cities like Genoa and Venice contributed to the astronomical advances in navigation, and, by coincidence, Venice was the world's greatest glass-blowing center. Furthermore, the fine marble dust from the quarries at Carrara was perfect for use as sand in navigational sand clocks. As well as measuring time as distance at sea, hourglasses were used by the navies of several nations to "keep the watch" or measure the time the crew worked. The ship's boy was in charge of turning the hourglass; to get off work early, he would "swallow the sand" or turn the glass before it was empty.

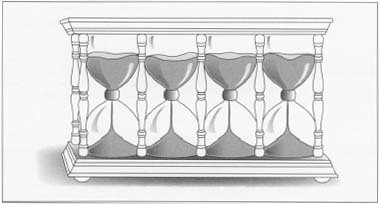

The most extraordinary hourglasses were made as gifts for royalty. Charlemagne (742-814) of France possessed a 12-hour hourglass. In the sixteenth century, Holbein (1497-1543) the artist made spectacular hourglasses for Henry VIII (1491-1547) of England. Other sand glasses contained multiple instruments. For example, a sand glass made in Italy in the seventeenth century contained four glasses. One had one-quarter hour of sand; the second, a half-hour of sand; the third, three-quarters of an hour of sand; and the fourth contained the full hour's measure of sand. Some glasses also had dials with pointers, so, with each turning of the glass, the number of turns could be shown with the pointer to mark the cumulative passage of time.

The upper and lower globes of each glass were blown separately with open apertures or throats. To join them so that sand could flow from the upper globe to the lower, the two halves of the glass were bound together with cord that was then coated with wax. The two-coned glass phial could not be blown as one piece until about 1800.

In about 1500, the first clocks began to appear with the invention of the coiled spring or mainspring. Some weight-powered clocks had been made before 1500, but their size limited their practicality. As the mainspring was improved, smaller, tabletop clocks were manufactured and the first watches were made. Mainspring-driven clocks made curiosities out of clepsydras and sand glasses, but, interestingly, the most beautiful hourglasses were made after 1500 as decorative pieces. These are the hourglasses that are displayed in museums.

By the 1400s, many private homes had sand clocks for household and kitchen use. Sermonglasses were used in churches to track the length of the minister's sermon. Hourglasses were also routinely used in the lecture halls of Oxford University, craftsmen's shops (to regulate working hours), and in England's House of Commons where bells to signal voting and lengths of speeches were timed based on sand clocks. During the height of the sand glass, doctors, apothecaries, and other medical practitioners carried miniature or pocket sand glasses with durations of one-half or one minute to use when timing pulses; the practice of carrying these continued until the nineteenth century. Today, miniature versions containing three minutes worth of sand are sold as egg timers and as travel souvenirs. Larger sand clocks are still made today of ornamental materials and in interesting styles for use as decoration. All of these measuring devices (clock candles, water clocks, and sand clocks) have the disadvantage that they must be watched carefully.

Raw Materials

Glass for hourglasses is the same material as that used for other blown glass. It is manufactured in tubes of varying lengths by specialized suppliers for firing and shaping by machine or by mouth-blowing. Pre-formed light-bulb blanks can also be transformed into hourglasses by joining them together at the bases of the bulbs. Similarly, jars can be hooked together at their necks to make hourglasses; these can range in appearance from rustic to modern depending on the "character" of the jars.

The frames or housings for hourglasses are open to the designer's whims. Raw materials most often consist of pieces of fine wood that can be crafted or carved to suit a particular style, decor, design, or theme. Bamboo, resin, and various metals like brass, bronze, and pewter are also beautiful framing materials. Specialized hourglasses are made in such small numbers that raw materials are purchased from outside sources for limited

Sand is the most complex of the components of hourglasses. Not all types of sand can be used because the grains may be too angular and may not flow properly through the neck of the hourglass. White quartz sand, the sand found on sparkling white beaches, is attractive but not the best for hourglass-making because it is too angular and does not flow smoothly. Marble dust, other rock dust and rock flour—powder from glass cutting—and round sand grains, like those of river sand, are best for sand clocks. During the Middle Ages, books for homemakers included recipes not only for cooking but for making glue, ink, soap, and also sand for hourglasses. Perhaps the best sand isn't sand at all; ballotini, tiny glass beads or shot (like miniature marbles about 40-160 microns [0.00016-0.0063-in or 0.0004-0.0016-cm] in diameter) are used in hourglasses because their round edges flow smoothly through the glass. In addition, ballotini can be made in different colors so the sand in the hourglass can be chosen to match room decor or some other color preference.

Design

Design and conceptualization are usually the most complicated part of hourglass making. The hourglass maker must be craftsman, artist, and public relations expert in advising clients of the practicalities in hourglass design and construction. Businesses are commissioning hourglasses as gifts related to the year 2000, but they also want to reflect the character of their business or incorporate materials associated with their products. After the design is finalized, actual construction of the hourglass is relatively straightforward.

Sand-clock designs can also vary considerably in size. The smallest known hourglasses are the size of a cufflink, and the largest are up to 3 ft (1 m) tall. The glasses can have various shapes from round to oblong and can be engraved. Multiple (more than two) glass gloves can be linked together, and several hourglasses can be mounted in the same frame and turned on a turnstile.

According to one craftsman, hourglass design has no limits. He develops his own designs, makes hourglasses based on designs or requests provided by his customers, or creates designs to suit a particular market interest. He has sculpted pairs of his own hands as frames to hold the glasses, used unusual materials like bamboo or marble to craft the frames, and called on other hourglasses, such as the gargoyle-framed hourglass in the movie version of The Wizard of Oz, for his inspirations. He has made hourglasses containing coal sand, mining slag, sand from the Great Wall of China, and polyethylene resin sand. Shopping networks on television are currently selling hourglasses that are futuristic in design in keeping with interest in the new millennium.

The Manufacturing

Process

- After the design and materials are selected, the body of the hourglass is blown on a glass lathe to a size appropriate for the size (time interval) of the hourglass.

- The frame is made; depending on its design, it may be a single piece or multiple pieces including a bottom, top, and three or four posts. This manufacture depends on the material. If the frame is made of resin, molds may be constructed, the resin is poured in and allowed to cure, the pieces are sanded or otherwise smoothed and polished, and they are fitted together. Frame pieces may be fitted to interlock; or they may be glued, bonded, or welded, again depending on the materials involved.

- One of the most common misconceptions about hourglasses is that there is a formula for the quantity of sand contained in the glass. The sand quantity in a given hourglass design or shape is not based on science or a measurement formula. The types of grains, the curves of the glass, and the shape and size of the opening impose too many variables on the rate of flow of the sand through the glass, so the amount of sand can not be mathematically calculated. Before the top of the frame is sealed, sand is added and allowed to flow through the glass for its prescribed time interval. At the end of that time period, sand remaining in the top of the glass is poured off and the glass is sealed.

Quality Control

Quality control is inherent in the manufacture of hourglasses because the designer or manufacturer does all aspects of the work. The customer is also involved in conceptualizing the design and choosing materials and colors. The end result is that customers receive handmade products that suit their requirements and evoke historic and artistic associations; hourglasses are aesthetically pleasing ornaments, rather than accurate timepieces.

Byproducts/Waste

Minor quantities of waste result from hourglass construction, depending on the types of materials used. Wood that is carved to make the hourglass frame will create some waste, for example. Glass that is too thin or flawed can be melted and blown again. Excess quantities of sand can be saved for future use.

The Future

The hourglass would seem to have no future. In fact, the beautiful shape of the glass itself and its custom-made frame and colored sand can be selected to suit decor, atmosphere, or occasion. While future production may be limited, the hourglass as an object with ancient associations as well as built-in elegance will always appeal to collectors and those who appreciate the mysteries of art and time.

Where to Learn More

Books

Branley, Franklyn M. Keeping Time: From the Beginning and into the Twenty-first Century. Boston: Houghton Mifflin Company, 1993.

Cowan, Harrison J. Time and Its Measurement: From the Stone Age to the Nuclear Age. New York: The World Publishing Company, 1958.

Guye, Samuel and Henri Michel. Time & Space: Measuring Instruments from the Fifteenth to the Nineteenth Century. New York: Praeger Publishers, 1970.

Smith, Alan. Clocks and Watches: American, European and Japanese Timepieces. New York: Crescent Books, 1975.

Periodicals

Morris, Scot. "The floating hourglass." Omni (September 1992): 86.

Peterson, Ivars. "Trickling sand: how an hourglass ticks." Science News (September 11, 1993): 167.

Other

The Hourglass Connection. http://www.hourglass.com/ (June 29, 1999).

— Gillian S. Holmes

I'm interested in the value and any other info you might be able to give me judging by the pic.

What I know, it's brass.. solid, magnet does not stick to it.

It's about 10.5" tall and is accurate to the last grain of sand. Trust me I checked it along time ago. A OCD person's delight, checking the accuracy of a Hourglass.

Thank you for whatever help you can give me.

img.photobucket.com/albums/v204/zbestwun2001/hourglass.jpg