License Plate

Background

Metal plates attached to motor vehicles are commonly called license plates, but this is a misnomer. The driver of the vehicle must be licensed, and the vehicle is registered; therefore, these plates are really registration plates. In some states, especially in the South, the plates are also called license tags. The information printed on the plate, either in the metal itself or on one or two attached stickers tells authorities about the registration of the vehicle and about the owner.

The American states and Canadian provinces have separate departments or administrations for motor vehicles and their own systems for coloring, issuing, and numbering the plates. For law enforcement, distinctions are made in color combinations, captions or words embossed on the plates, and combinations of alpha and numeric characters that provide identification to those trained in decoding them. Various classes of vehicles, weight and use restrictions, validity of registration, and information about the owner and the vehicle are communicated on the license plate.

Currently, all the states and provinces issue license plates that are permanent or semipermanent; they are intended to last throughout the ownership of the vehicle or for some period longer than one year. To revalidate the plate when registration fees are paid annually, decals are issued for the vehicle operator to stick on the plate. Out of the 51 U.S. jurisdictions (the 50 states and Puerto Rico), 31 require two plates for each vehicle, one for the front and one for the back. The remaining jurisdictions only require a rear plate. The trend, however, may move to one plate only because of the cost of manufacture.

License plates on passenger cars may include information about the county of the owner's residence, the owner's occupation, expiration codes related to vehicle registration, government department codes, and special codes for officials and certain groups like disabled drivers. Commercial vehicles like buses and trucks usually have plates of a different color and with different codes than those for passenger vehicles; their license plates are also changed more frequently.

The reasons for these differences are taxes. Owners of commercial vehicles pay several different taxes, over and above the registration fees, depending on miles driven, fuel use, and vehicle weight. Taxes are computed based on formulas for these factors. Interstate traffic is also complicated because the taxes from vehicle registration and taxes are essential for highway maintenance and new construction. States apportion fees among themselves based on the vehicle's portion of highway use in each state; the displays of license plates and decals on some vehicles hint at these complexities.

History

Before license plates came vehicle registration bureaus. States realized as early as 1892 that some form of regulation was becoming necessary with the increase in the number of motorized vehicles. Automobiles, horses, and pedestrians were causing roads to deteriorate rapidly, and regulations—and funds—were needed to correct the problem. Public safety was also a grave issue, and law enforcement officials needed a device to help them keep records regarding vehicle owners and their actions. License plates came into existence in 1903 when it became apparent that motor vehicles were sure to replace horse-drawn carriages and that a system of registering and taxing them and their drivers was needed. Massachusetts was one of the first states to issue licenses for drivers and registration plates for vehicles.

Funnily, many license plate terms refer back to the early history of the automobile or even to the days of horses and carriages. Vintage vehicles bear Horseless Carriage license plates in many states, and historical vehicle plates are issued to owners whose vehicles were manufactured after 1922 (varies by state) and are at least 25 years old. In Alabama, some trucks are licensed to operate in an area with a 15-mile radius. This is an outdated form of measurement based on the distance a mule can travel in one day, so plates on these trucks are termed mule tags. In the early dates of motorcycle registration, small plates were mounted on the motorcycles and the drivers were required to carry brass watch fobs bearing the registration information.

Vehicle operators were concerned that front-mounted plates would block the flow of air to the radiator, so some states made slotted plates to reduce this hazard; this practice was discontinued in about 1918. The first plates were made of sheet iron, but tin became the standard by about 1920. The State of Arizona made its tags from sheet copper in 1932-1934. Porcelain plates were also quite common in the early days of vehicle plates, and Delaware was the last state to make porcelain plates in 1942. During World War II, soybean-based fiberboard was used for license plates because of the need to devote all available metal to the war effort; goats were particularly pleased with this development because the license plates made tasty snacks.

Also in about 1920, the states began using the labor of inmates in their correctional institutions to manufacture registration plates to provide useful work for the prisoners and also to keep plate production costs down. The states began to require that automobile builders provide lights for illuminating license plates in about 1923. The first reflectorized plate was issued in the State of Georgia in 1941, and Georgia was also the pioneer in the use of decals to update registration information, rather than issuing new plates every year. Plate sizes were not standardized until 1957 when the dimensions of 6 x 12 in (15.24 x 30.48 cm) were selected.

From the early days of license plates to about 1965, many states also showed police troop codes, county designations, or congressional districts on their vehicle plates. By 1991, only 10 states continued any of these practices, although county name decals are affixed to the plates from some other states. Computer technology is largely responsible for this change because fewer codes are needed for quick identification of vehicles.

Raw Materials

The raw materials used to make license plates include sheets of aluminum, preprinted and colored reflective and adhesive sheeting, and paint. The aluminum blanks are usually precut to size by metal manufacturers and supplied in this form to correctional institutions or other plate makers.

Decals for annual registration renewals, county designations, or other uses are made by specialty printers on reflective sheeting much like that used to cover the license plates themselves.

Design

Design of license plates is limited to a standard size and thickness that will fit license-plate mounts on most vehicles. Other properties like colors and reflective coatings are continuously improved for visibility, primarily to aid in law enforcement.

Beyond these restrictions, license plate designs can be quite creative. Personalized plates, also called vanity, custom, or prestige plates, have become popular in the last three decades when states recognized the cash benefits of appealing to the public's individuality. Canada calls these personalized number plates (PNPs). In California, the revenue from vanity plates is dedicated to environmental projects, so such plates are called environmental license plates (ELPs).

Other special plates are made to survivors of the attack on Pearl Harbor and recipients of

Special category plates are another variety of license plate that is becoming increasingly popular. These include plates recognizing graduates of colleges and universities and veterans of military service and plates dedicated to a number of causes such as the Astronauts' Memorial commemorating the Challenger Space Shuttle disaster; Florida uses sales of this plate to raise funds for the memorial. Florida has also used other special category plates to raise funds to protect the manatee and the Florida panther and to commemorate the twentieth anniversary of Disney World and the five hundredth anniversary of Columbus's discovery of the New World; in fact, Florida has produced over 50 specialty tags. Again, computers have made these plates possible because it is no longer essential for a plate from California, for example, to be blue and gold for law enforcement professionals to recognize the home state of the vehicle.

The Manufacturing

Process

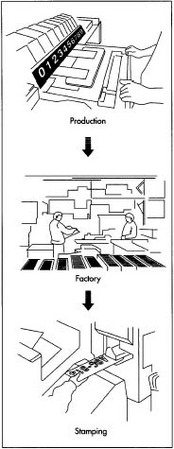

O/d method

Most license plates are still made in correctional institutions, although some states contract out plate manufacture to private companies.

- Metal blanks are inserted into presses and stamped with rounded edging and a series of characters, usually including both numbers and letters.

- The whole plate is painted in its main color, and the raised characters (and sometimes decorations) are painted in a contrasting color with an automated roller that is set to the correct height to only paint the raised elements.

- The two-color plate is then treated with reflective coating. This is a paint-like substance made of extremely fine glass beads that refract (bend) light and bounce it back at many times the brightness of the paint alone. Plates made by this method are usually considered partially reflective because the application of the reflective coating over the dual levels of the plate is not uniform.

New method

- Modern license plate manufacture applies a preprinted sheet to the unstamped metal blank. This preprinted sheeting has the main color of the plate as well as multicolored decorations. It also has reflective material in the coating on the sheet. The sheet is affixed to the blank, the sheet-covered blank is stamped to create the raised characters, and the characters are colored with ink.

- The ink allows the reflective material to shine through completely and uniformly, so these plates are described as fully reflectorized. The ink is less durable than the paint, however, so these plates are also given a clear, protective coating. The reflective sheeting makes license plates easier for law enforcement officials to read by the light of headlights or flashlights, and it is more effective as a safety device on the highway. It does make license plates more expensive to manufacture.

Quality Control

State motor vehicle departments establish the rules for license plate manufacture under the direction of the State legislature. The Interstate Commerce Commission also has requirements for plate manufacture particularly with respect to interstate traffic, licensing, and taxes. Number designations, the numbers and letters appearing on vanity plates, and special interest plates are all approved well in advance of production by the state motor vehicle authority, which also oversees manufacture in correctional institutions and private companies. Quality control during actual manufacture is by observation; the stamped metal plate is inspected, as is the coated and painted plate before packaging and distribution.

Byproducts/Waste

No byproducts are made from license plate manufacture, although a considerable industry has arisen for making collectible plates for sports teams, those bearing first names and nicknames, and humorous plates with puns and jokes in the number and letter combinations.

Little waste results from plate making. The metal blanks are sized to limit metal Other Minor amounts of trimmings from the sheets of reflective coating material are simply disposed.

The Future

License plates are here to stay at least for the foreseeable future. This tried-and-true method of tracking vehicle ownership and operation is useful for law enforcement, a variety of taxes, registration, and other data. The future may see devices like bar codes or scanner codes incorporated into license plates or directly into vehicles. When the code is read by a scanner (a handheld model for police officers and fixed models for other applications), the complete history of the vehicle and information about its operation and ownership would be available by computer almost instantly. The bar codes might also include other fees like bridge tolls that would be billed to the vehicle owner.

License plates as we know them are also experiencing second lives, thanks to collectors. The Automobile License Plate Collectors Association (ALPCA) is one of several organizations for hobbyists who collect historical plates and those from different locations. ALPCA awards one state per year with a coveted "Best Plate Award" based on a competition among the discerning members of ALPCA. To encourage collectors and tourism, many states and provinces also sell sample plates. Their variety, colorful designs, and historic associations make license plates attractive both on the road and in the enthusiast's collection.

Where to Learn More

Books

Murray, Thomson C. License Plate Book. Jericho, New York: Interstate Directory Publishing Company Inc., 1992.

Periodicals

Tooley, Jo Ann. "GR8 PL8S." U.S. News & World Report (August 12, 1991): 9.

Other

American License Plate Collectors' Association. http://www.alpca.org/

State of Massachusetts Registry of Motor Vehicles. http://www.state.ma.us/rmv/

— Gillian S. Holmes

Comment about this article, ask questions, or add new information about this topic: