Sword

Background

The development of the sword was not possible until ancient civilizations discovered how to mine and work metal. Thus, the first swords were probably made of the oldest worked metal, pure copper. The earliest copper mines were in Egypt around 3700 B.C. , and in Anatolia (in what is now Turkey) around the same time. By about 1900 B.C. , copper working had spread across Europe, and presumably copper swords were made during this era. Copper alloyed with tin produces bronze, and this metal made stronger weapons than pure copper. The earliest bronze swords were made by the Egyptians in about 2500 B.C. They made blades by heating bronze ingots or by casting molten metal in clay molds. Bronze swords were used throughout the ancient world, until bronze was replaced by iron as the metal used to make weapons. The Hittites knew how to smelt iron as early as 3000 B.C. , but an efficient method of forming the iron into blades was not discovered until somewhere around 1400 B.C. The Hittites were the first to harden iron for blades by heating it with carbon, hammering it into shape, and then quenching it in water. They kept their methods secret for as long as they could, but gradually ironworking spread across the ancient world. The Romans used iron swords with double blades, a weapon for hand-to-hand fighting. A bigger sword, which could be used to fight from horseback, came into vogue in Western Europe by the third century. Both the Vikings and Saxons were renowned swordsmiths. They used sophisticated ironworking techniques both in forming and decorating their blades.

During the Middle Ages in Europe, the sword was the preferred weapon of the knight in armor. The medieval sword was made of steel, and so sharp and heavy that it could easily cut a man in half. The quality of the sword depended to a great extent on the quality of the metal. Production of swords was specialized in certain towns or areas where skilled ironworkers had access to good metal and knew how to work it. From the sixth century, the lower Rhine in Germany was a center of sword manufacturing, and later swords were exported from Milan, Brescia, and Passau. Toledo, in Spain, was renowned for its swords. A test of the Toledo sword's sharpness was to throw a silk scarf into the air so that it floated down onto the sword blade. The edge was so sharp that the silk would rend on impact.

Perhaps the strongest swords ever made were the weapons of the samurai in Japan. As far back as the eighth century until the end of the feudal period in the nineteenth century, Japanese smiths made blades of exceptional hardness by welding strips of iron and steel together, then folding the resulting sandwich over on itself and pounding it flat again. This process was repeated from 12-28 times. Old blades were passed down in families, and some were still in use in World War H. These swords were so sharp and strong they could cut through a machine gun barrel.

During the sixteenth century, the sword evolved from a slashing weapon into a more refined thrusting rapier. The rapier had a long, thin blade sometimes reaching 6 ft (1.83 m) in length. When carried at the waist, the longest of rapiers would inconveniently hit the street. By the end of the century, the rapier became more lightweight and its length was shortened to 3 ft (0.91 m). These adjustments gave birth to swordplay and expertise.

With swordplay arose the art of the duel, a privilege primarily reserved for the upper class. From 1600-1789, 40,000 aristocrats lost their lives in duels. Since Germans preferred heavier swords, dueling was often violent and resulted in injury and death. It was tolerated by the ruling monarchs because of its rigid exclusion of the lower classes. In Germany, dueling as an aristocratic sport unified the upper classes and distinguished them from the masses. In France, dueling was more of an art that did not necessarily have to end in injury or death. With the French Revolution and the abolition of aristocracy, dueling was considered a sport for all. The French used lighter weight epees—a sword with no cutting edge that tapers to a point—and duels were usually fought until the first blood was drawn. By the end of the nineteenth century, Frenchmen averaged 400-500 duels per year with a nonexistent death rate. The English banned dueling in 1844.

Swords declined in utility after the introduction of firearms, though they persisted for a surprisingly long time. The British army was still perfecting its sword design in the first decade of the twentieth century, and its last change in design was in 1920. The cutlass, a wide sword used in the British Navy, was not withdrawn from service until 1936. Swords made today are for the most part ceremonial. They are still part of some military dress uniforms. The only place where swords are actually still employed as weapons seems to be Japan, where they are said to be a choice murder weapon of underworld gangsters and far-right political assassins.

Fencing as Sport

With the refinement of sword design and the popularity of dueling came the sport of fencing. During the eighteenth century Domenico Angelo, an Italian that studied swordsmanship in Paris, moved to London and gained a reputation as an expert duelist. Challenged by Ireland's master swordsman Dr. Keys, Angelo quickly out-maneuvered Dr. Keys' slashing techniques with his own fencing moves. His victory made Angelo popular with the upper class as a teacher of dueling. He opened a school and fencing as sport was established.

Modern fencing is done with blunted foils, epees, and sabers. A typical uniform is equipped with a padded jacket, gauntlets, and wire-mesh helmets. It is an official Olympic sport and it's popularity has been sustained by the romantic swashbuckling of early Hollywood films and recent epics like Star Wars and Braveheart.

Raw Materials

The swords commonly in use in Europe in the Middle Ages were made of steel. Steel is an alloy of iron and carbon, and iron heated properly over a charcoal fire becomes steel. But the theory behind the process was not understood until the nineteenth century, and not many communities knew how to make good steel. Iron smelters roasted ore in charcoal fires, and produced wrought iron, cast iron and carbon steel, depending on the heat and makeup of the ore. Cast iron contains more than 2.2% carbon. It is too hard to work, and until the fourteenth century in Europe, it was considered a waste product. Wrought iron contains less than 0.3% carbon. It is a soft, workable metal most used for tools. But wrought iron swords bent in use, and so were inferior to steel ones. Steel suitable for swords contains from 0.3-2.2% carbon, and it is both soft and workable and can be hardened by heating it to red hot and then quenching it in water.

Until the fourteenth century, when the mechanical bellows was invented and iron production became more organized in Europe, production of steel was haphazard, and primitive furnaces produced steel more by luck than design. The invention of the bellows and the blast furnace in the fourteenth century allowed smelters to heat ore to higher temperatures, producing wrought iron that could be converted to steel. A common kind of steel available in Medieval Europe was called blister steel. It was made from thin rods of wrought iron. The iron rods were packed in charcoal dust and set inside a tight iron box or small furnace. The iron was heated in the furnace and blown with the bellows. When the iron reached white hot, it began to absorb carbon from the charcoal, and turn to steel. Rods of small diameter

The finest steel was imported from India, called Wootz steel. Indian metallurgy was renowned from the time of the Roman Empire, and blades made in the Persian Empire and across the east were usually made from imported Wootz. European Crusaders encountered Wootz steel in the superior weapons of their eastern enemies. Crusading knights began bringing Wootz steel back to Europe in the eleventh century, but the secret of making it remained in India until the nineteenth century. Blades made from Wootz showed a grainy pattern in the metal, formed by the fibrous layout of crystals in the steel. The appearance has been compared to watered silk, or damask fabric. The swordsmith usually emphasized the pattern by etching the blade with acid. The most skilled smiths could make the crystalline pattern appear in regular formations along the blade. This ancient art is now lost. Eastern blades with patterned metal are called Damascus swords, named after the city that was a major east-west trading point. To confuse matters, some European swords are also called "Damascus." In this case, European smiths tried to copy the eastern swords by marking blades and inlaying the metal. But in true Damascus blades, the patterning is inherent in the steel itself, and not imposed on it.

Indian metallurgists had several ways of preparing Wootz steel. In one method, wrought iron plates were immersed in a crucible filled with molten cast iron. Cast iron has a high carbon content, and when heated, the carbon leached from the cast iron to the wrought plates. The resulting metal was a mixture of soft iron and hard carbon steel, dispersed in granules throughout the ingot. Another method was to crush iron ore and

The Manufacturing

Process

Different metal workers made swords in many different ways, and most of the techniques of swordmaking were never written down. In general, specialized smiths made swords. The finishing of the blade, which often involved elaborate inlay work, was done separately by a jeweler. Then the blade was sometimes sent to a cutler, who did the final assembling of the blade in the grip. What follows is a general process for a type of sword made with an iron core and steel blades. A Roman sword was presumably made this way, as were the swords of Toledo.

Forming the core

- 1 Some swords were made with a core of wrought iron, and fitted with steel blades. The softer center made the weapon more flexible and resilient. The core is formed from twisted rods of iron. The smith takes two or more thin iron rods and heats them in the forge until they are white-hot. Then, the smith fastens one end of the rods in a vice, and twists them all together using a pair of tongs. One long narrow piece is left to protrude from the center of the bundle. This forms the tang that holds the sword to its hilt.

Drawing out

- 2 The twisted rods are then "drawn out"—a smith's term for making the iron thinner. The metal is heated to an orange-red, then placed on the anvil. The smith strikes the metal with measured blows that stretch the body and make it long and sword-shaped.

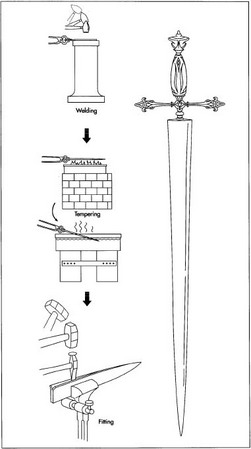

Fitting the blades

- 3 Next, the smith fixes the iron into a vice and opens a seam along the edge with a heated tool. A thin piece of steel that has been roughened or "scarfed" along one edge, is then set into the groove. The smith then heats the metal so that both the iron and steel are molten on the surface. This was evidently quite an art, as the metals had different melting temperatures. The smith closes the seam by hammering it deftly, and the molten metals join. For a two-edged sword, the process is then repeated on the other side.

Packing the edge

- 4 Now, the smith heats the blade so it barely turns red. The smith often held the blade in the shadow of a box or barrel, to see the color in the dark. When the whole length of the blade is the right color, the smith sets it on the anvil and strikes quick blows with a small hammer all along the steel edges. This masses the steel fibers, and makes a stronger weapon that keeps its sharpness longer.

Tempering

- 5 Now the blade is tempered—transformed from soft, workable metal into a hard blade. The smith holds the blade over a fire that may be a long fire built specially to fit swords. The difficulty is in getting an even heat all along the length of the metal. When every part is glowing an even color, the smith quenches the blade in a vat of oil or brine. For this first quenching, the blade is placed in the vat with the blade held flat, parallel to the liquid's surface. After it cools, the smith cleans off the metal scale that collects on the blade's surface. Then, the smith heats the sword again, in a slightly different way. The smith heats a long iron bar to orange-red, and lays the sword on it. When the sword heats to a blue or purple color, the smith lifts it with tongs and quenches it again, this time edge down (perpendicular to the first quenching).

Filing and grinding

- 6 The blade is next polished with a series of fine files. The edges are ground sharp on a grindstone, a rotating wheel of textured stone.

Decorating

- 7 Many blades were elaborately decorated with inlaid patterns. Usually the sword was sent to a jeweler for this step. The jeweler engraved a pattern on the metal, and then often etched it out with acid.

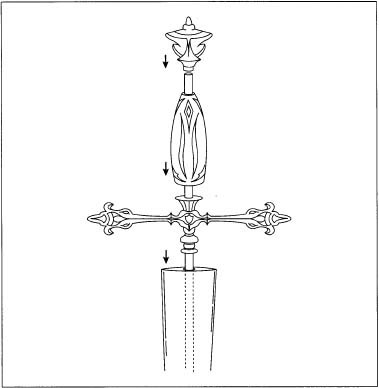

Assembling

- 8 For the final step, the blade is attached to a hilt. The smith had made the blade with a narrow piece called the tang protruding from the end of the sword opposite the tip. The smith prepares a crosspiece with a hole punched through the center. The simplest grip was usually made of wood. It was carved as a solid piece, and then the smith, (or cutler, if a specialist did the finishing) bored a hole through it from end to end. A third piece is called the pommel. It is the rounded end of the grip. It would also be carved in one piece, and drilled end to end. Then, the smith heats the tang, and fits the pieces over it. The hot metal bores out and fills the holes in the pieces, and effectively joins them. The tang is long enough that a bit of it still protrudes through the pommel. This is folded over and tacked down.

Byproducts/Waste

The production of iron and steel for swords required massive amounts of charcoal. Charcoal is made from slowly charred wood. The amount of trees needed to provide charcoal was so enormous that Queen Elizabeth I of England had to put a limit on how much timber could be felled, fearing her country would run out. An ironworks in colonial America that produced 15 tons of iron a week used up about four square miles of forest each year. So iron production on a massive scale ran into the danger of deforestation.

Iron itself was usually assiduously recycled. Old nails and horseshoes made excellent sword cores, and smiths usually kept a scrap heap of broken or useless tools and parts that could be melted down and re-used. An unskilled smith, however, could waste steel if he burnt the narrow edge of a blade. If heated too high, the steel became brittle and useless. And in this condition, it was not recyclable.

Where to Learn More

Books

Bealer, Alex W. The Art of Blacksmithing. New York: Funk & Wagnalls, 1969.

Evangelista, Nick. Encyclopedia of the Sword. Greenwood Publishing Group, 1995.

Figiel, Leo S. On Damascus Steel. New York: Atlantis Arts Press, 1991.

Oakeshott, Ewart. A Knight and His Weapons. Chester Springs, PA: Dufour Editions, 1997.

Wilkinson-Latham, Robert. Swords in Color. New York: Arco Publishing Company, 1978.

Periodicals

"Murder a la Mode." The Economist (April 29, 1995).

— Angela Woodward

Comment about this article, ask questions, or add new information about this topic: