Tuba

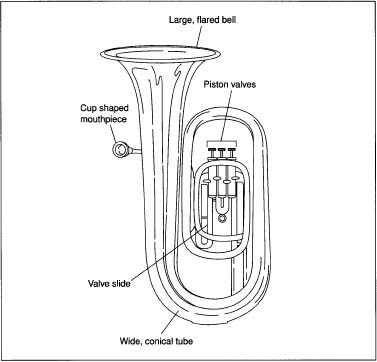

A tuba is a brass instrument characterized by its large size and deep sound. It consists of vertically coiled tubing, three or four valves, a wide conical bore, flared bell, and a cup-shaped mouthpiece. The different segments of the tuba are shaped and bent from machinable brass using standard techniques. The pieces are then soldered together to complete the instrument. First built in the early nineteenth century, the tuba was invented to provide a bass sound in brass ensembles.

Background

Tubas belong to a class of instruments known as brass wind instruments. The sounds that these instruments make are produced by the buzzing of the musicians lips against the mouthpiece. This causes the column of air inside the instrument to vibrate. As it exits the instrument through the bell, audible sound is created. The tone that is heard is directly related to the length of tubing through which the air traveled. By engaging a valve, the tubing is shortened or lengthened and the tone is changed. In an orchestra, the tuba is used to produce the lowest notes. Depending on the type of tuba it can reach notes as low as bottom D of the piano. It is often used to play quick staccato solos but can also play sustained melodies.

History

The development of the tuba began during the early nineteenth century. During the 1820s, various instrument manufacturers produced the ophicleide, a precursor to the tuba. It was a type of keyed-bugle instrument that could reportedly produce a pitch as low as F. However, these instruments were difficult to play and were never truly embraced by the music community. To satisfy the desire of bandleaders for a valved brass instrument that was capable of playing low notes the tuba was invented.

In 1835, the first bass tuba was patented by Johann Gottfried Moritz (an instrument maker) and Wilheim Wieprecht (a bandmaster) It was completely distinct from the keyed ophicleide in that it was equipped with a new type of short piston valve called the Berliner-Pumpe. Their prototype tuba looked different than the modern tuba but it shared some key characteristics. For example, it was pitched in F, the standard pitch of orchestral tubas. It had five valves that could lower the pitch of the instrument. It was also made from brass with silver fittings.

Next, Moritz and Wieprecht designed a wider-bored instrument that they called a bombardon. It had the same general shape as the ophicleide but also had valves. Their design was adopted by other instrument makers who modified them slightly and began producing the bombardon in different sizes and shapes. Within a few years, rotary valves were used instead of the Berliner-Pumpe valves. In 1845, Adolfe Sax patented a family of sax-horns that ranged from sopranino to contrabass. The lowest member of these instruments closely resembled the modern tuba.

In 1849, the hellicon bass was introduced. This was an instrument with a circular coil that was designed to rest on a player's shoulder. It first gained popularity in Great Britain brass bands because of its ease of portability. In the 1860s the famous American bandleader, John Philip Sousa, commissioned C. G. Conn to produce a more audience-friendly version of the hellicon. The instrument was later known as the sousaphone.

When the tuba was first introduced, it rapidly replaced the ophicleide in bands and orchestras in Germany. It was more slowly accepted by other countries, particularly Britain and France. By 1880, the tuba had become the standard brass bass instrument and the ophicleide was obsolete.

Design

The general design of the tuba has changed little since the early days of its development. It is a massive instrument with a large bell of anywhere from 14-30 in (35.56-76.2 cm) in diameter. The main tubing is shaped in an elliptical coil with the bell pointing up. There are numerous variations on this shape however. For example, the sousaphone is a circular shaped instrument with the bell pointing forward. Certain upright tubas have also been made with a forward pointing bell. Other tubas have left or right facing bells. The position of the bell is important because it affects the overall tone quality the instrument produces.

Most tubas have four valves that are of the piston variety. However, certain instruments have anywhere from two to six valves. Rotary valves are also used for certain brands of tubas. These valves are faster than piston valves but less durable. A large, cup-shaped mouthpiece is used. Tubas are available in five different keys including double B flat, double C, E flat, F, and the double G contrabass bugle.

Raw Materials

The primary raw material used for making standard tubas is brass. Brass is an alloy composed of copper and zinc. Other metals that may also be added to modify the characteristics include tin and nickel. The most common type used in the construction of instruments is yellow brass that contains a 70/30 blend of copper and zinc. This material is yellow in color and malleable. Other types of brass are also used when different effects are desired. For example, red-gold brass, which is composed of 80% copper and 20% zinc, provides a more gold color and a slightly different sound. Silver brass that includes copper, zinc, and nickel is also used.

The zinc in brass makes the alloy workable at lower temperatures. Some custom manufacturers use special blends of brass for different parts of the tuba. For example, a material such as Ambronze which is composed of 85% copper, 13% zinc, and 2% tin, may be used to make the bell. This material gives the instrument a unique sound.

Beyond brass, only a few other materials are used to make the tuba. Most of the screws are composed of stainless steel. In some cases, certain surfaces on the instrument such as the valves or the sliding pipes are coated with chromium or a nickel alloy. This reduces friction and helps the pieces move more freely. During production, flux and solder are used to connect the various tubes. To reduce the possibility of damage, valves are lined with felt where the valve button meets the instrument body. For decoration, a material such as mother of pearl is used on the valve button. Cork may also be used to line the water key. To reduce weight, the bulk of the sousaphone is composed of fiberglass.

The Manufacturing

Process

The demand for tubas is much less than for other brass instruments such as trumpets, bugles, or trombones. Therefore, production is not typically done in a highly automated fashion. The three general steps of production include piece forming, assembly and final finishing.

Piece making

-

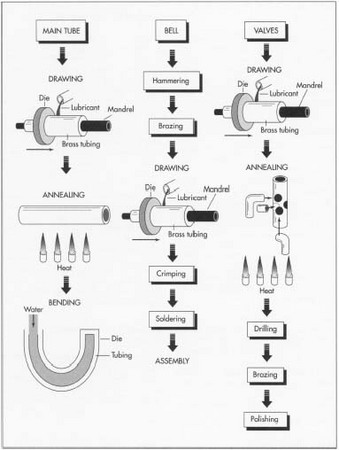

1 The main body, valves, bell, and mouthpiece are produced separately

during manufacture. In some cases, these different parts may be made by

various contractors who ship them to the tuba manufacturer for assembly.

The main body is made by first putting a tube of brass on a pole-shaped

mandrel. Lubrication is applied, and then a doughnut shaped die is drawn

down the mandrel to reshape the brass giving it a consistent shape and

thickness. The tube is then heated to make it more workable. It is then

soaked in sulfuric or nitric acid to remove the oxide that is formed by

the heating process.

A tuba is made up of a main body, valves, bell, and mouthpiece. All parts are manufactured from brass in various drawing, hammering, and bending operations.

A tuba is made up of a main body, valves, bell, and mouthpiece. All parts are manufactured from brass in various drawing, hammering, and bending operations. - 2 The modified tubes are then moved to another area where they are bent to form the appropriate curves and angles necessary for the correct tone. Various bending methods are employed. In one procedure, the tube is first placed in a die that matches the desired curve. This requires a small bit of mechanical bending. Water is then pumped through the tube at high pressures, causing the metal to expand and automatically take on the shape of the die. Another bending technique employs a ball bearing that is sent through the pipe. Here, the ball bearing works much like the water forcing the walls of the tube to conform to the die.

-

3 The valve system is made using many of the same techniques as the main

tube. The casing is first cut from a long piece of tubing. It is

threaded on the ends to allow the valves to be taken apart more easily.

Using computerized systems, holes are drilled into the casing which

match up exactly to the holes in the pistons. The pistons are also

constructed similarly. The knuckles, which are pieces of tubing that

connect the main tube to the valves, are bent into the different angles as required for the instrument. They are then heated, or annealed, and washed in an acid bath to remove oxides. The whole assembly is held together in jigs and the joints are soldered together with a blow torch. It is then sent for another acid wash to remove excess solder and oxide, and then to a polishing machine.

A tuba.

A tuba. - 4 The bell is produced from a large brass sheet that is cut to a flat dress shaped pattern. It is then wrapped around a sufficiently wide pole and pounded into shape. At the narrow end of the bell, the ends are soldered together in a butt joint. Where the bell widens, the ends are designed to overlap. They are connected using a lap joint which is then brazed with high temperatures to ensure the proper seal. The narrow end is then drawn on a mandrel to make it the same size as the end of the main tube. The wider end is then hammered further to give it a more of a bell shape. A small wire is attached to the rim of the bell and the metal is crimped around it.

- 5 While the mouthpiece may be made using various metals, brass is often used. It is made by pouring molten metal into a two-piece die. The die is brought together and held under pressure for a set amount of time. It is then allowed to cool causing the metal to harden. After a short time, the mold halves are opened and the mouthpiece is ejected.

Assembly

- 6 All the parts of the tuba can then be assembled. The valve assembly is joined to the main tube and soldered. The bell is also soldered to the main tube. The pistons are inserted into the valve casings and then screwed onto the main tubing. Other pieces such as the water key or thumb rings are also soldered on at this point.

Final finishing

- 7 The tuba is then cleaned and polished. It may also be electroplated with a gold of silver alloy to change its appearance. The company name is engraved on the metal using automatic or manual techniques. The instrument may then be put in a lightweight, felt-lined case along with the mouthpiece and other accessories. These are further packed in heavy boxes and shipped to customers.

Quality Control

The quality of each tuba part is checked during the various phases of manufacture. The primary test method is visual inspection. Inspectors check for things such as deformed parts, inadequate welds, and other variations. In addition to visual checks, more rigorous measurements can also be performed. Measuring devices such as a vernier caliper or micrometer as used to check the length, width and thickness of each part.

The sound quality of the instrument is also checked prior to shipment. Manufacturers may employ professional musicians who can verify that the tone and pitch are within standards set for the specific model of instrument. Depending on the thoroughness of these tests, the instrument may also be checked under different acoustical settings

Where to Learn More

Books

Whitener, Scott. A Complete Guide to Brass. Schirmer Books, 1990.

Phillips, H and W. Winkle. The Art of Tuba and Euphonium. Summy-Birc, 1992.

Othmer, Kirk. Encyclopedia of Chemical Technology, 1992.

Other

United States Patent 5,644,095. 1997.

United States Patent 5,012,714. 1991.

— Perry Romanowski

1.Mouthpeices are generally made with nickle. but, they can be made with a varitity of metals. (stainless steel, plastic, brass, gold plated nickle)

2. some manufactures have speacialists that stay with one horn till its done. the y dont send it off. but some do (like you said)

3. the sousaphone was commisioned by John Phillip Sousa to J.W. Pepper, who, designed it and named it after

sousa because it was his idea. (sorce: JW pepper.com). The first sousaphone had an upright bell and was actually intended for concert usd because the Helicon was to 'forward' for a concert setting.

These are a few things i thought i might just point out. This is a very informative artical.

Thanks

Andrew the Tuba player