Drain Cleaner

Background

Drain cleaners, sometimes referred to as drain uncloggers, are solutions that are poured into sluggish or clogged drains in order to clear them. These solutions are devised to dissolve human hair, human waste, or food particles that stop up kitchen sinks or tub and shower drains. These drain cleaners may take a variety of forms. Some are powders, but most are liquids that may be poured directly into the drain. There are two types of drain cleaners available today. One is the conventional, chemical drain cleaner, the other is the bio-degradable, environment-friendly, and chemical-free drain cleaner.

The chemical drain cleaner is by far the most popular drain cleaner sold in the United States as it is far more effective than the biodegradable drain cleaner. There are two types of chemical drain cleaners manufactured in the United States. One type is acid-based and includes chemicals such as sulphuric acid. This is the most effective drain cleaner of the two chemical types but is by far the most dangerous. Sulphuric acid immediately eats away at any organic material that it comes in contact with. This means the acid effectively eats away at human waste and hair that may be in a sink, quickly unclogging drains. However, it also means that the acid eats at organic material such as skin. So if the drain cleaner splashes onto the user, the user has little time to wash off the acid before it starts eating and burning at the skin. The other type of chemical drain cleaner is made of caustic sodium hypochloride. The well-known chemical drain cleaners made by large national firms primarily produce the caustic drain cleaners. Caustic drain cleaners are cheaper to make than acidic drain cleaners, not as effective, and a little safer to use as sodium hypochloride does not immediately burn the skin and can be washed off before significant damage is done.

The chemical drain cleaners must be used with extreme caution. The manufacturers recommend that they be used with gloves and goggles because the chemicals have been known to splash into the face and eyes and cause burns to the eyes. More serious concerns revolve around a consumer's inadvertent mixing of drain cleaners with other household chemicals and generating extremely dangerous vapors that can harm the user. Finally, the chemicals should be kept far out of reach of young children.

The bio-degradable drain cleaners simply clean the drains and generally do not unclog them, as they are not particularly effective at eating away the organic material. Some plumbers recommend these safer products as they feel chemicals actually damage pipes and plumbing, as well as possibly wreaking damage to the water supply once dumped down the drains.

History

Drain cleaners do not have an extensive history as indoor drains hooked up to a municipal plumbing system were not common in middle-class homes until the early twentieth century. Prior to that time Americans poured water from pitchers into basins to wash up and then discarded the dirty water. Drains without significant mesh drain covers clog quickly. It seems likely that lye, a caustic substance made from hardwood ashes and water, was poured down the drains when they became sluggish. Less dangerous concoctions of vinegar and baking soda were combined to make minor bubbling in the sink as well and was supposedly another way to clear a drain. Some plumbers physically snake out a drain using a long flexible, metal plumber's snake that physically pushes through the drain obstruction.

The large bleach manufacturers in this country realized by the mid-twentieth century that the sodium hypochloride they produced for bleach could also be used to make a liquid plumbing solution. Produced in somewhat greater strength than bleach, the caustic drain cleaner eats through the organic material that clogs the drains. Acidic drain cleaners, somewhat more expensive to make and hazardous to human contact, is produced by specialty or smaller firms and is often sold to plumbers or for commercial use.

Raw Materials

Drain cleaners require only the acquisition and mixing of a few chemicals. Acidic drain cleaners are made from sulphuric acid and a few additives (generally proprietary information). Sulphuric acid is an indirect byproduct of the purification process related to iron ore. Today, the majority comes from Canada where much of North America's iron ore is produce. Sulphuric acid is the chemical compound H 2 SO 4 , is colorless, odorless, oily, and extremely corrosive. It reacts immediately to organic material and is dangerous to human skin. It reacts with many metals, particularly zinc, and mixing tanks must be made from metals that do not react to it. Drain cleaner manufacturers use steel for mixing and filling tanks as steel does not react with the sulphuric acid.

Caustic drain cleaner is sodium hypochloride, an alkaline substance made from the mixing of chlorine, sodium hydroxide (sometimes called caustic soda), and water. Surfactants are added into the caustic drain cleaners. Surfactants, or surface-active agents, may be added to reduce surface tension, promote mixing of solutions, and reduce foaming.

The Manufacturing

Process

Acid-based drain cleaner and alkaline drain cleaner are manufactured using very similar steps.

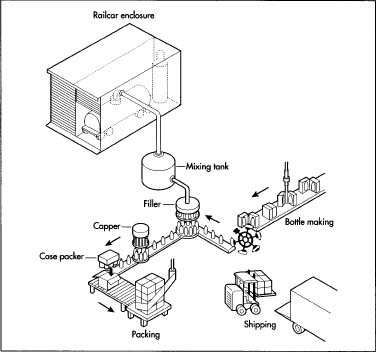

- Huge tanks of sulphuric acid—brought up to the tanks via rail cars or very large tank trunks-is pump the chemical directly into large bulk tanks within the factory. Enclosures are often brought around the tankers to ensure that fumes do not escape from the hoses or tanks and dangerous fumes or chemicals are released into the atmosphere. Hoses connect the distribution tanks with the tanks within the building because the solution is very dangerous to human skin. Human operators never touch any of these materials directly in any part of the manufacture of chemical drain cleaners.

- The sulphuric acid is then transferred into another tank known as a mixing tank. Other additives are added to the sulphuric acid in order to make the acid effective, but slightly more dilute (so that the mixture is not pure sulphuric acid). The combination or choice of additives is considered part of the manufacturers' trade secrets and is generally not revealed. This implies the kinds of additives and their relative strengths varies greatly from manufacturer to manufacturer.

- These ingredients are carefully mixed so they are evenly distributed within the mixing tank.

- When the mixing is complete, the solution (now drain cleaner) is ready for dispersal into containers. The drain cleaner leaves the mixing tank and is fed into a filler tank that is outfitted with a nozzle or nozzles. Empty containers enter a turntable in which a mechanical head lowers a nozzle into the container, fills it with a pre-determined amount of fluid, and the filled bottle is then moved to the side. The bottles are automatically sealed and capped. These individual containers are always heavy-duty and are generally of thick polyethylene plastic. The container must not be easy to shatter, leak, spill, or be etched by the acid as the drain cleaner is extremely dangerous to the touch. The acidic drain cleaner is now ready for distribution.

-

Caustic drain cleaner is manufactured using very similar manufacturing

techniques. The primary difference is that the caustic drain cleaner

must have more additives infused into it to make a viable drain cleaner.

After mixing, just as in the production of acidic drain cleaner, the

solutions are

fed into the filler tank and dispersed into individual heavy-duty containers and sealed and capped.

The production cycle of drain cleaner.

The production cycle of drain cleaner.

Quality Control

Manufacturers heavily rely on suppliers who certify their products to be of the grade and strength of solution needed to produce effective drain cleaner that is still safe for ordinary household use. However, the solutions are periodically tested to ensure they are as presented to the manufacturer. The testing is carefully performed as the solutions are difficult to handle and can be dangerous to the tester. Hoses, fillers, and tanks must be carefully and vigilantly maintained to ensure that no dangerous solutions are leaked at any point during manufacture.

Byproducts/Waste

There is virtually no waste with the manufacture of drain cleaner. The solutions go from one tank directly into another without human intervention. Unless batches are not mixed correctly, which very rarely occurs, all of the solution is placed into containers for sale.

The disposal of chemicals no longer wanted or needed by the consumer is a problem. Many suggest that the unused product must be taken to a hazardous household waste collection center available in larger municipalities. If not available, then it is suggested that the chemicals are poured down the sink with plenty of water. The chemicals must not be poured into a septic system. Similarly, the retail packaging once it is emptied by the consumer is somewhat of a problem. The container is considered contaminated with caustic or acidic chemicals and really should not be recycled despite recycle-compatible materials. They must be disposed of in the garbage, and then sent to landfills.

The Future

There is significant discussion about the continued use of acidic and alkaline drain cleaners. Many environmentalists are ardently opposed to their use as once they are poured down drains the acids (sulphuric acid) and alkalines (chlorine and sodium hydroxide) are released into the water supply. Some areas of the country have drains that have ties to lakes and ponds and these chemicals may be released into the environment. Environmentalists have worked hard to promote plumbing products that are deemed to be environmentally safe. These drain cleaners are varied in ingredients; the most successful of the products are bacteria or enzyme-based. These enzymes eat through sludge and are said to liquefy matter that clogs the drains such as grease, food particles, human waste and human hair. When released into the drain, and then into the water supply, these enzymes do not appear to upset the ecosystem nor harm the water supply for animal consumption.

While these environmentally-friendly products may be less harmful to the environment they are not particularly popular. They are not terribly effective and generally considered more of a cleaner rather than a drain unclogger. Some householders tend to prefer the less effective, environmentally-friendly drain cleaners simply because they are much safer to use. Sometimes the chemical solutions splash up into the eyes when poured into a clogged sink. Plumbers or homeowners may have to stick their hands in the water to check the drain and are then burned by the solutions they have poured into the drains. These chemicals can be difficult to use safely and are considered a hazard to have around children.

Where to Learn More

Books

Ierley, Merritt. Open House: A Guided Tour of the American Home. New York: Henry Holt and Company, 1999.

Ierley, Merritt. The Comforts of Home. New York: Clarkson Potter, 1999.

Rybczynski, Witold. Home: A Short History of an Idea. New York: Penguin Books, 1986.

Other

Clorox Web Page. December 2001. < http:www.clorox.com >.

Oral interview with Dennis West, Plant Manager of Rooto Corporation. Howell, MI. October 2001.

"Surfactants." Encyclopedia Britannica CD Edition. Encyclopedia Britannica Inc., 1994-1998.

Nancy EV Bryk

Comment about this article, ask questions, or add new information about this topic: