Epilation Device

Background

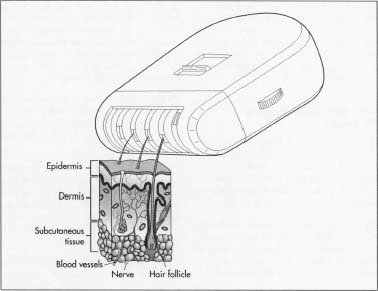

Epilation refers to removal of hairs from below the skin's surface. Examples of epilation devices include tweezers, waxes, electrolysis, and laser hair removal. These types of hair removal devices and methods are continually improved to diminish skin irritation, increase ease of use, increase the time between hair removal methods, and decrease pain. Epilation devices currently strive to remove the entire hair from the root using mechanical extraction or laser removal.

The original and most popular epilation device is the Epilady. Through tremendous and innovative marketing, Epilady quickly became a success in the hair removal arena. Despite legal issues surrounding the patent for this product, Epilady has remained a leader in the development and consumer satisfaction for electronic epilation devices. As a result of the consumer's familiarity with the product through advertising, the Epilady brand name has become generic, much like Kleenex, and may be used to refer to all electric epilation devices.

There are two commonly used designs for electronic epilation devices. One epilating head consists of a series of small tweezing mechanisms that grasp individual hairs and pluck them out. The second type of epilating head has a disc system. Several metal discs rotate in opposing directions to grip and pluck out the hair and its root. These methods do not destroy the actual follicle nor prevent regrowth permanently, but results may last several weeks.

History

Throughout history man has experimented with various means of removing hair. The reasons for hair removal range from social status to function to hygiene, and have resulted in diverse methods for performing this task. Many of the hair removal techniques used today are derived from these original methods, such as waxing, shaving, and using depilatory creams. The more advanced methods like electronic epilators, electrolysis, and laser hair removal, were developed only recently because the technology to create such devices was previously unavailable.

The late 1700s saw the first manufactured razor, but it lacked safety capabilities and the search to develop a safety razor ensued. It wasn't until the eighteenth century that the first instrument specifically designed as a safety razor appeared. Invented in 1762 by a French barber, Jean Jacques Perret, the safety razor had a metal guard placed along an edge of the blade to prevent the blade from accidentally cutting into the shaver's skin.

A traveling salesman-inventor named King Gillette launched the first shaving revolution almost single-handedly. In 1895, he conceptualized a razor with disposable blades. However, collaboration with William Nickerson, a professor at the Massachusetts Institute of Technology, was necessary before the product could successfully be brought to market in 1903. In 1915, Gillette introduced Milady Décolletée, a razor created especially for women.

In 1931, the year Gillette retired, Jacob Schick challenged the razor blade with the invention of the electric shaver. Schick's shaver was in turn challenged by Remington, who introduced the dual-headed shaver and the first electric shaver designed especially for women in 1940.

In 1986, an Israeli-based company began marketing Epilady, the first electronic hair removal device. This form of epilation used a tweezing method to extract hairs by the roots, which resulted in longer periods between hair removal. Despite its reputation for causing pain, it became an international success and revolutionized hair removal.

A newly designed Epilady arrived on the market in 1996 called "Discrette." This was the first epilator with a disc-operated head. It boasted a virtually pain-free experience because of the high velocity movement of the rotating discs.

Since then, several other versions of Epilady have been developed. Most of these specialize in specific areas like the face, underarms, and bikini area. In addition, other companies such as Phillips, Braun, and Emjoi have developed similar electronic epilators based on the original Epilady design. Due to enhancements that decrease pain, increase the area to be depilated, and provide longer lasting results, electronic epilation devices are reemerging as a popular means for hair removal.

Raw Materials

The housing for the epilation device can be made of a variety of insulative materials such as plastic, nylon, or any other nonconductive material. There is also a rubber-like gripping surface included on the housing to prevent slippage during use. Metal and electrical mechanisms such as wires and insulative components are manufactured for inclusion in electrical epilation devices.

Design

The two primary designs of an electric epilating device are a rotating disc epilator and a rotating tweezing barrel.

The original electronic epilators were designed using rotary cylinders with pivotal axes, which can adjust the zone of the closing action allowing the device to adapt to changing contour surfaces of the skin. Attached to the rotary cylinders are several small plucking components.

Disc-operated epilators are a newer design and usually cause less pain than the rotary tweezer head. These epilators use high velocity rotating discs that quickly grasp hairs and pluck them out at the root. Because the discs move so rapidly, they are able to catch shorter hairs and cover larger areas in less time.

In both cases, the hairs to be plucked-out are trapped between the projecting portions of the epilation blades or discs. These hairs are then gripped or pinched between the projecting zones of two successive tweezing parts. Finally, these hairs are ejected by centrifugal force during the stage of opening of the gripping zones as the rotating barrel or disc completes its cycle.

The Manufacturing

Process

- Motor-powered epilating devices are manufactured from a hollow cylinder enclosed by the housing that is used as a handgrip. A molding press is used to create the plastic housing. A pellet of encapsulating material, such as plastic, is placed in a die.

- The encapsulating material is heated until it melts and fills the molding press. After allowing the encapsulating material to cool and solidify, the molding press is opened and the molded parts are separated.

- The exterior of the housing is sprayed with a heat shrunk rubberized coating to provide a comfortable grip.

- An epilator head and frame comprise the top of the device. The head frame is molded in a similar manner as the housing. It is usually formed by a molding press using a plastic-like material. The head frame has an opening through the top allowing exposure of the epilating head, and attaches to the main housing unit either by interlocking components or screws.

- The epilator head is a roller-type component made of metal. Alternating arrangements of fixed and movable blades are mounted on the roller head. The moveable blades, which are the tweezing elements, and fixed blades are formed from a non-corrosive metal, which both heated and poured into a mold. Once the molded metal cools, the blades are sharpened with a filing saw. The various blades each have a polygonal shaped central opening to permit the insertion both of the rotary shaft and of the different bars and strips. Each piece is individually cut by a metal die cutter. The fixed and movable blades are held together with a series of small screws or by inserting a thin metal pin through holes at the base of each part. The pin itself is mounted into each end of the housing unit.

- The rotary shaft of the epilation head is placed between two end plates that are soldered to the cover and carry the bearings in which the shaft-ends are mounted. A thin metal bar is positioned as an axis between the rotating head and the small electric motor that powers the device.

- The axis is driven in rotation by the small electric motor, which is also housed within the casing. Power for the motor is derived from a dry cell battery positioned near the motor.

- Against two opposite faces of the shaft, two flat metal strips are mounted that hold the epilation blades in position. Against each of the two other faces of the shaft are mounted two additional thin metal bars capable of sliding in a direction parallel to the axis of the shaft.

- The sliding bars of each pair are machined with a series of transverse grooves. The teeth of the blades are engaged in the grooves of the two bars. Therefore, the epilation blades are coupled with each of the two sliding bars of one and the same pair in alternate sequence.

- Once all of the metal components are fastened together and mounted to the motor, the remaining plastic housing is attached. This ensures that the unit is fully enclosed and interior components will be protected.

- The completed unit moves on for final inspection and packaging prior to arriving in stores.

Quality Control

The major risk of motor driven devices is electrical shock, which can occur if the electrical components are not properly insulated. Therefore, manufacturers evaluate the insulating materials throughout the design process. Devices are left switched on in a protective container and effects of the accumulated heat are evaluated on the durability of the device and its safety.

Health risks associated with the hair removal appliances are typically infections resulting from unsanitary conditions. It is the consumer's responsibility to ensure that home devices are properly sanitized. The United States Food and Drug Administration can take action against products that are found to cause damage. Laser hair removal devices are prescription devices and should only be used under a licensed practitioner's guidance. These devices have been approved by the USFDA for hair removal.

The company who manufactures the Epilady devices, Mepro, complies with IS09002 regulations. These international standards help ensure quality control at all levels of the manufacturing process in order to reproduce parts and assemble them with efficient and repetitive methods.

Byproducts/Waste

The waste from the plastics and moldable parts that are incorporated for the housing are melted and reused. Electrical components are tested and either passed on for further inspection or dismantled and reassembled depending on the severity of the design.

The Future

Manufacturers of epilation devices have been making great strides to improve the effectiveness of their products, reduce the pain and irritation associated with use of epilators, and increase the amount of time between hair removal. Some of these enhancements include plating the tweezing components with 24-karat gold for better sanitation and hypo-allergenic qualities. The speed and number of tweezing components has also been increased so that a greater area can be covered in a faster amount of time. Quicker rotation of the plucking elements will also reduce pain.

Permanent depilatory devices are becoming more popular. They use high frequency electricity to destroy hair-producing papilla at the base of the hair shaft. Unfortunately, many of these devices involve large and expensive equipment requiring a visit to a salon. An improved tweezer mechanism using a compressible coil spring attached to a first and a second arm, where the hair is grasped between the coils of the spring and pulled from the body may be more cost effective and functional. The primary advantage is that the coil spring can grasp multiple hairs simultaneously.

Lasers have been used for many years for medical cosmetic procedures. Laser hair removal is non-invasive and can remove unwanted body hair without damaging the surrounding pores or structures of the skin. Optical energy is used that is of a wavelength sufficient to cause epilation in the cavity, therefore limiting damage to tissue outside of the hair root structure. A laser that may be operated in a pulse mode and contained in a hand piece having the optical system at the end generates the beam. During application of the laser energy, the root structure and the hair, if present, is progressively ablated and vaporized until the bottom of the hair bulb is reached at which time the beam is turned off.

Where to Learn More

Periodicals

Segal, Marian. "Hair Today, Gone Tomorrow." FDA Consumer Magazine (September 1996).

Other

"Electrolysis Manufacturers." Hairfacts.com Web Page. December 2001. < http://www.hairfacts.com/makers/epltrmfr.html >.

"Epilady Story." Epilady Web Page. December 2001. < http://www.epilady.com/profile.html >.

"The Shaving Historical Timeline." The Quik Shave Body Razor Web Page. December 2001. < http://www.quikshave.com/timeline.htm >.

United States Patent and Trade Office. December 2001. < http://patft.uspto.gov >.

Stacey L. Blachford

Bonny P. McClain

Comment about this article, ask questions, or add new information about this topic: