Felt

Background

Most fabrics are woven, meaning they are constructed on a loom and have interlocking warp (the thread or fiber that is strung lengthwise on the loom) and weft (the thread that cuts across the warp fiber and interlocks with it) fibers that create a flat piece of fabric. Felt is a dense, non-woven fabric and without any warp or weft. Instead, felted fabric is made from matted and compressed fibers or fur with no apparent system of threads. Felt is produced as these fibers and/or fur are pressed together using heat, moisture, and pressure. Felt is generally composed of wool that is mixed with a synthetic in order to create sturdy, resilient felt for craft or industrial use. However, some felt is made wholly from synthetic fibers.

Felt may vary in width, length, color, or thickness depending on its intended application. This matted material is particularly useful for padding and lining as it is dense and can be very thick. Furthermore, since the fabric is not woven the edges may be cut without fear of threads becoming loose and the fiber unraveling. Felted fibers generally take dye well and craft felt is available in a multitude of colors while industrial-grade felt is generally left in its natural state. In fact, felt is used in a wide variety of applications both within the residential and industrial contexts. Felt is used in air fresheners, children's bulletin boards, craft kits, holiday costumes and decorations, stamp pads, within appliances, gaskets, as a clothing stiffener or liner, and it can be used as a cushion, to provide pads for polishing apparatus, or as a sealant in industrial machinery.

History

Felt may be the oldest fabric known to man, and there are many references to felt in ancient writings. Since felt is not woven and does not require a loom for its production, ancient man made it rather easily. Some of the earliest felt remains were found in the frozen tombs of nomadic horsemen in the Siberian Tlai mountains and date to around 700 B.C. These tribes made clothing, saddles, and tents from felt because it was strong and resistant to wet and snowy weather. Legend has it that during the Middle Ages St. Clement, who was to become the fourth bishop of Rome, was a wandering monk who happened upon the process of making felt by accident. It is said he stuffed his sandals with tow (short flax or linen fibers) in order to make them more comfortable. St. Clement discovered that the combination of moisture from perspiration and ground dampness coupled with pressure from his feet matted these tow fibers together and produced a cloth. After becoming bishop he set up groups of workers to develop felting operations. St. Clement became the patron saint for hatmakers, who extensively utilize felt to this day.

Today, hats are associated with felt, but it is generally presumed that all felt is made of wool. Originally, early hat-making felt was produced using animal fur (generally beaver fur). The fur was matted with other fibers—including wool—using heat, pressure, and moisture. The finest hats were of beaver, and men's fine hats were often referred to as beavers. Beaver felt hats were made in the late Middle Ages and were much coveted. However, by the end of the fourteenth century many hatmakers produced them in the Low Countries thus driving down the price.

The North American continent was home to many of the beaver skins used in European hatmakers' creations in the eighteenth and nineteenth centuries. North American Indians' second-hand skins, replete with perspiration, felted most successfully and were in extraordinary demand for hatmaking in both the New and Old Worlds. The beaver hat was surpassed in popularity in the second half of the nineteenth century by the black silk hat, sometimes finished to resemble beaver and referred to as beaver-finished silk.

The steps included in making felt have changed little over time. Felted fabric is produced using heat, moisture, and pressure to mat and interlock the fibers. In the Middle Ages the hatmaker separated the fur from the hide by hand and applied pressure and warm water to the fabric to shrink it manually. While machinery is used today to accomplish many of these tasks, the processing requirements remain unchanged. One exception is that until the late nineteenth century mercury was used in the processing of felt for hatmaking. Mercury was discovered to have debilitating effects on the hatter causing a type of poisoning that led to tremors, hallucinations, and other psychotic symptoms. The term mad hatter is associated with the hatmaker because of the psychosis that stemmed from the mercury poisoning. Hats of wool felt remain quite popular and are primarily worn in the winter months.

The use of felt has enlarged over the past century. Crafts enthusiasts use it for all types of projects. Many teachers find it to be an easy fabric for children to handle because once it is cut the edges do not unravel as do woven fabrics. Industrial applications for felt have burgeoned, and felt is found in cars as well as production machinery.

Raw Materials

Felt is produced from wool, which grips and mats easily, and a synthetic fiber that gives the felt some resilience and longevity. Typical fiber combinations for felt include wool and polyester or wool and nylon. Synthetics cannot be turned into felt by themselves but can be felted if they combine with wool.

Other raw materials used in the production of wool include steam, utilized during the stage in which the material is reduced in width and length and made thicker. Also, a weak sulfuric acid mixture is used in the thickening process. Soda ash (sodium chloride) is utilized to neutralize the sulfuric acid.

The Manufacturing

Process

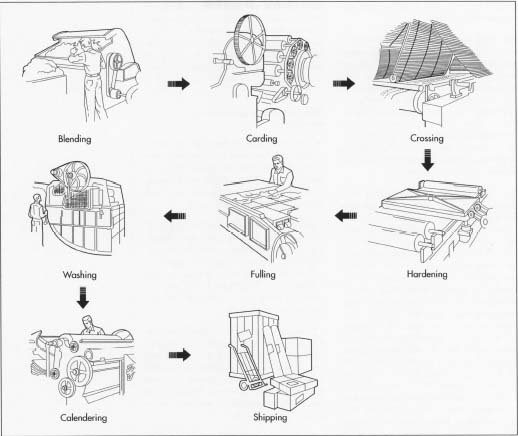

- Since some felts use more than one type of fiber, the fibers must be mixed and blended together before any processing begins. To do this, the raw fibers are put into an opener with a big cylinder studded with steel nails that combine the fibers into a mass.

- Next, these blended fibers must be carded. Carding machines are huge cylinders that mat the fibers into a web. Hopper-feeders allow a specific weight of fiber to pass into the cylinder in order to create a standardized web. The fibers in the web are pulled by the wires, or carded, so that they are parallel to one another.

- Generally, at least two carding machines are used in the manufacturing process, each refining the web as it creates a new one. A transporter moves one web from the first carding machine to a second. The web is then fed into the second machine. This second carder generates a new web that is thicker and fully carded.

- At the end of the second carding, a comb removes the carded web from the machine and rolls it up. There are two ways to remove the web from the machine: a cross-lapper may be used in which the web is perpendicularly rolled up, or across the direction of the fibers; or a vlamir may be utilized, in which the web is rolled parallel to the direction of the fibers.

-

Next, several different webs are combined to create one thick web. Four

rolls of web are rolled up but are layered so that their fibers

alternate in direction based on the way the webs were rolled, either

cross-lapped or rolled using a vlamir. These four rolls are considered a

standard single roll, sometimes referred to as a batt. This batt is

considered a standard roll of material. Batts are layered in order to

create different thicknesses of felt.

The manufacturing process of felt.

The manufacturing process of felt. - The batts of felted material must be hardened or matted together in order to create thick, densely-felted material. The first step in this process is subjecting the batts to heat and moisture. In order to do so, the batts are passed through a steam table.

- Now, the separate batts must be matted together and shrunk in length and width in order to create a dense felt. These batts must be subjected to heat, moisture, and pressure in order to be matted densely. First, the wetted batts are fed into a plate-hardener that shrinks the width of the fabric. The plate-hardener consists of a large, square flat bed with a large plate that drops down over the batts of wet, hot batts, exerting pressure on the material and compressing it. At the same time, the plate-hardener oscillates from edge to edge, further matting the fiber to a specific width.

- Next, the batts are fed into a fuller or fulling machine, which shrinks the length to a specific measurement. As it shrinks, the felt becomes more dense. The batts are fed through a set of upper and lower steel rollers that are covered with hard rubber or plastic and are molded with treads much like a car tire, enabling them to move across the batts. The felt is continuously wetted with a hot water and sulfuric-acid solution. The upper rollers remain stationary as the lower rollers are moved upwards to put pressure on the fabric and push it against the upper rollers. All of the rollers, both upper and lower, move together forward and backward. The pressure, the acid, the hot water, and the movement causes the batts to shrink in length, making the felt even more dense. For example, a single piece of felt that is 38 yd (34.7 m) long may come out of the fuller at only 30 yd (27.4 m) in length.

- The wet felt has sulfuric acid residue and must be neutralized. To do so, the felt is run through neutralizing tanks filled with a soda ash and warm water solution. This process is carefully timed so that specific yard lengths and widths are in for an exact amount of time.

- The neutralized felt is then run through a refulling machine in which heavy rollers run over the surface of the fabric one last time to smooth out any irregularities.

- If felts are to be dyed, the wet pieces are taken to a dye vat. Some industrial grades are not dyed but go directly to drying.

- Some companies simply roll up the wet felt and send it to a centrifugal dryer that spins out the water. Others have huge dryers in which the felt is pinned in place on a dryer bed. Felt can also be open-air dried by either being hung or stretched out on a floor in a drying room.

- Once dry, some companies press or iron the felt to ensure consistent thickness. Some manufacturers use this ironing to make dense felts even more dense as ironing can shrink it slightly.

- The finishing step includes placing the felt on a gaging table in which the edges of the felt are neatly trimmed. The piece is now ready for packing, labeling, and shipping.

Quality Control

Quality control begins with the arrival of the materials. Materials are checked for quality and weight. Some companies purchase wool that has been scoured and baled; the purity of the bales is examined upon entry. Other important quality control checks include continuous monitoring of the carded webs, since the web sizes are important first steps in producing the desired length and width of the felt. Once the batts are shrunk in width and length, the company checks the weight, density, width, length, and evenness of the batts. When production is complete, visual checks may reveal that the surface of a batt is slightly uneven and additional pressing may occur to even out the surface. The acid baths are also very carefully monitored. The amount of time the fabric is in the acid bath is precisely calculated by weight and length of yard good, lest the piece is ruined. Finally, the company producing industrial felt has to check its goods against a governmental standard for the product. The government has determined that 16 lb (7.3 kg) density felt must be 1 in (2.5 cm) thick, 36 in (91.4 cm) wide, 36 in (91.4 cm) long, and weigh 16 lb (7.3 kg). If the felt weighs less than this, the fabric is not dense enough and does not meet government expectations for that grade of felt.

Byproducts/Waste

There is some waste generated in felt production. When the edges are trimmed, small pieces are cut off. These small pieces are often impregnated with oil and grease from the machinery and are unusable for other purposes. These materials are then sent to a landfill.

The Future

Due to its extreme versatility, the demand for felt is consistent. It is used in military applications for helmets, boots, small ammunitions, and rockets. The civilian uses of felt are too numerous to count. A unique use has been found for the excess white felt ground that is relatively clean and clear of oil and grease. It is ground up, colored, and put into an aerosol can. It is then sold as a spray to cover bald spots and has been somewhat successful in recent years.

Where to Learn More

Books

Gioello, Debbie Ann. Profiling Fabrics. New York: Fairchild Publications, 1981.

McDowell, Colin. Hats: Status, Style and Glamour. New York: Rizzoli, 1993.

Other

Design Arcade Web Page. November 2001. < http://www.designarcade.com/history/historyfelt.htm >.

Interview with Dick Pursell. Director of Sales, U. S. Felt. Sanford, ME. August 2001.

Sutherland Felt Company. Manufacturing of Wool Felts Wet Process. Troy, MI.

Nancy EV Bryk