Straight Pin

Background

A straight pin is a small length of stiff wire with a head at one end and a point at the other end. It is used to fasten pieces of cloth or paper together.

History

Since their ancient beginnings, human beings have devised methods for securing cloth together. Prehistoric people used thorns as pins. In ancient Egypt, pins were crafted of bronze with decorative heads. The clothes of medieval Europeans were adorned with pins of many materials including bone, ivory, silver, gold, and brass.

The use of iron wire, still applied during modern times, began as early as the fifteenth century in France. The craft of tailoring was also well-established by this time. Descriptions of a tailor's equipment from Spanish books dating back to this period included the mention of pins. A "paper of pins" became a familiar cultural phrase, signifying the possessions of the simplest nature.

At the dawn of the Industrial Revolution in the eighteenth century, noted economist Adam Smith employed the imagery of a pin factory as the perfect example of the intricate division of labor. In his book, Wealth of Nations, published in 1776, Smith described how one worker drew out the wire, another straightened it, a third cut the wire, the fourth sharpened one end, and another worker ground the opposite end for the attachment of the head. At the end of the process, the pins were polished and inserted into paper packets. These early pin factories produced just under 5,000 pins per day.

Attaching the heads presented a particular challenge. In the early to mid-1800s, American inventors Seth Hunt and John Ireland Howe and British inventors Lemuel Wright and Daniel Foote-Taylor patented machines that produced pins with a solid head from a single piece of wire. American Samuel Slocum also invented a similar machine but did not patent it. In spite of not having an official claim to this invention, the pins manufactured in Slocum's Poughkeepsie, New York factory became known as Poughkeepsie pins.

A physician by profession, Howe also liked to tinker with machinery. After watching the inmate/patients at the New York Alms House laboriously make pins by hand, he began to explore ideas for a pin-making machine. Howe enlisted the help of a printer press designer named Robert Hoe. Howe obtained a patent for his machine in June of 1832. After the machine was exhibited at the American Institute Fair in New York City, Howe was awarded a silver medal for his contribution to manufacturing.

In December of 1835, Howe formed the Howe Manufacturing Company, which was soon turning out about 70,000 pins daily. However, the packaging step slowed down the process. Workers had to manually insert the pins into paper or cards. In 1843, with the help of his employees, Howe developed a machine that crimped the paper and then inserted the pins.

Although electroplating was invented in the mid-1800s, the process was not perfect. The nickel coating would flake off and the pins would rust. To combat this flaw, tailors and seamstresses cleaned the rusted pins by pushing them back and forth into a bag of

Raw Materials

Blunt wire with an international steel regulation of ISR 9002 is generally used to make straight pins. To create the wire, a bar of steel is heated to a temperature of 2,200°F (1,200°C), rolled into a long thin rod, coiled, and then allowed to cool. The heating causes an oxide coating to form on the wire. To remove this coating, the wire is immersed in an acid bath, then rinsed in water.

The cleaned wire is inserted into a drawing block that pulls the wire through a die whose opening is smaller in diameter than that of the wire. Thus the wire is reduced in diameter and increased in length. The drawing is undertaken several times until the desired diameter is obtained. As it comes off of the last stage of drawing, the steel is coiled. The dies are coated with grease or soap to protect the wire as it passes through. This lubrication process also removes defects and gives the wire a smooth finish.

Nickel is a silvery chemical element extracted from the earth's crust. It is combined with sulfate to create a solution for coating the pins to keep them from rusting.

Design

The straight pin was designed to provide a simple function, secure two or more objects together. The design is relatively simple and unchanged. The sharp tip allows penetration through materials such as cloth and paper. The head of the pin stops the entire body from slipping through the hole created by the tip, thus creating a temporary bond.

The Manufacturing

Process

In the modern pin manufacturing plant, hundreds of thousands of pins are produced daily. Although several United States companies produce and sell straight pins, virtually all of the manufacturing plants are in Asia.

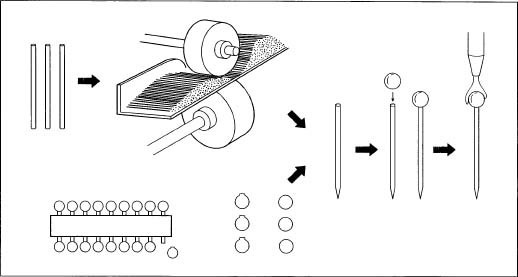

- One-hundred-foot rolls of steel wire are unwound by means of a roll straightener. The end of each roll is threaded into the straightener, which pulls the wire flat. Rotating blades cut the wire into pre-set lengths, usually between 1-1.25 in (2.5-3.2 cm) long.

- The cut wire travels via conveyer belt to the next station where the heads are "stamped" on. One end of the wire is slammed against a block. This sharp blow causes the end to mushroom out from the shank of the wire and create a flattened head.

- The pins are loaded into a circular cavity where they are hung by their heads over large grinding wheels. The grinding wheels spin the pins around to sharpen them.

- To ensure a strong bond between the pins and the plating solution, the pins are cleaned by dipping them in an acid solution. They are then are placed in a rack and lowered into large electroplating tanks filled with a plating solution such as nickel-sulfate. The pin rack is connected to the negative terminal of an external source of electricity. A second conductor is connected to the plating solution. A steady, direct electrical current of a low voltage, between one to six volts, is passed through the tanks. This causes the plating solution to coat the pins and give them a shiny finish.

- The shined pins are mechanically packed in pre-ordered amounts into plastic clamshell boxes or blister packs. Bar codes are mechanically affixed to each box or pack. The individual containers are then hand-packed into cartons for shipping.

Quality Control

When the wire arrives at the straight pin factory, it is inspected for physical properties such as tensile strength and brightness. Machinery is regularly checked while they are running. Samples are drained off from each electroplating bath and sent to on-site labs. A sample of pins is pulled from each batch of 20,000 and checked again for tensile strength and brightness. The count and weight of each batch is checked before and after processing.

Byproducts/Waste

The electroplating bath creates a toxic waste product that has serious implications for the environment. Companies that employ electroplating techniques are strictly regulated by the United States Environmental Protection Agency (EPA). The concentrations of metal in the electroplating bath must be removed or disposed of in a prescribed manner. The used solution or waste water cannot be emptied into a septic system or storm water sewer. Companies must use an authorized waste transporter and the containers must meet federal United States Department of Transportation packaging standards

Chromium, one of nearly 200 toxic chemicals regulated by the federal Clean Air Act, is released into the air during the electroplating process. Plants must apply for and be granted an air pollution control permit. To qualify for the permit, plants must meet standards that regulate the amount of emissions that are allowed per day, work practices, performance testing, monitoring, record keeping, and reporting.

One way in which manufacturers reduce the incidence of these pollutants is to limit the dragout and the use of water. Dragout is any solution that escapes from the electroplating solution. By allowing the pins and pin rack to drain completely over the bath, the dragout can be substantially cut. Drain boards between the process tanks and the rinse tanks catches any solution still remaining on the parts and the product.

Spray rinses installed over the baths wash the dragout directly back into the bath. Employing spray rinses rather than continuously flowing water also reduces the incidence of pollutants.

The Future

The straight pin has gone relatively unchanged for years and few improvements have been made. The head of the pin can now be either solid metal or plastic. Its use to bind paper together has been replaced by the stapler, but despite its simplicity, the straight pin is the first choice for a temporary way to bind cloth.

Where to Learn More

Books

Kane, Joseph Nathan, Steven Anzovin, and Janet Podell. Famous First Facts. New York: H. W. Wilson, 1997.

Petroski, Henry. The Evolution of Useful Things. New York: Alfred A. Knopf, 1992.

Travers, Bridget, ed. World of Invention: History's Most Significant Inventions and the People Behind Them. Detroit: Gale Research Inc., 1998.

Other

"Watch Your Waste." Illinois Environmental Protection Agency. 1 October 2001. < http://www.epa.state.il.us/small-business/electroplating-shops >.

Mary MeNulty

Comment about this article, ask questions, or add new information about this topic: