Vinegar

Background

Vinegar is an alcoholic liquid that has been allowed to sour. It is primarily used to flavor and preserve foods and as an ingredient in salad dressings and marinades. Vinegar is also used as a cleaning agent. The word is from the French vin (wine) and aigre (sour).

History

The use of vinegar to flavor food is centuries old. It has also been used as a medicine, a corrosive agent, and as a preservative. In the Middle Ages, alchemists poured vinegar onto lead in order to create lead acetate. Called "sugar of lead," it was added to sour cider until it became clear that ingesting the sweetened cider proved deadly.

By the Renaissance era, vinegar-making was a lucrative business in France. Flavored with pepper, clovers, roses, fennel, and raspberries, the country was producing close to 150 scented and flavored vinegars. Production of vinegar was also burgeoning in Great Britain. It became so profitable that a 1673 Act of Parliament established a tax on so-called vinegar-beer. In the early days of the United States, the production of cider vinegar was a cornerstone of farm and domestic economy, bringing three times the price of traditional hard cider.

The transformation of wine or fruit juice to vinegar is a chemical process in which ethyl alcohol undergoes partial oxidation that results in the formation of acetaldehyde. In the third stage, the acetaldehyde is converted into acetic acid. The chemical reaction is as follows: CH 3 CH 2 OH=2HCH 3 CHO=CH 3 COOH.

Historically, several processes have been employed to make vinegar. In the slow, or natural, process, vats of cider are allowed to sit open at room temperature. During a period of several months, the fruit juices ferment into alcohol and then oxidize into acetic acid.

The French Orleans process is also called the continuous method. Fruit juice is periodically added to small batches of vinegar and stored in wooden barrels. As the fresh juice sours, it is skimmed off the top.

Both the slow and continuous methods require several months to produce vinegar. In the modern commercial production of vinegar, the generator method and the submerged fermentation method are employed. These methods are based on the goal of infusing as much oxygen as possible into the alcohol product.

Raw Materials

Vinegar is made from a variety of diluted alcohol products, the most common being wine, beer, and rice. Balsamic vinegar is made from the Trebbiano and Lambrusco grapes of Italy's Emilia-Romagna region. Some distilled vinegars are made from wood products such as beech.

Acetobacters are microscopic bacteria that live on oxygen bubbles. Whereas the fermentation of grapes or hops to make wine or beer occurs in the absence of oxygen, the process of making vinegars relies on its presence. In the natural processes, the acetobacters are allowed to grow over time. In the vinegar factory, this process is induced by feeding acetozym nutrients into the tanks of alcohol.

Mother of vinegar is the gooey film that appears on the surface of the alcohol product as it is converted to vinegar. It is a natural carbohydrate called cellulose. This film holds the highest concentration of acetobacters. It is skimmed off the top and added to subsequent batches of alcohol to speed the formation of vinegar. Acetozym nutrients are manmade mother of vinegar in a powdered form.

Herbs and fruits are often used to flavor vinegar. Commonly used herbs include tarragon, garlic, and basil. Popular fruits include raspberries, cherries, and lemons.

Design

The design step of making vinegar is essentially a recipe. Depending on the type of vinegar to be bottled at the production plant—wine vinegar, cider vinegar, or distilled vinegar—food scientists in the test kitchens and laboratories create recipes for the various vinegars. Specifications include the amount of mother of vinegar and/or acetozym nutrients added per gallon of alcohol product. For flavored vinegars, ingredients such as herbs and fruits are macerated in vinegar for varying periods to determine the best taste results.

The Manufacturing

Process

The Orleans method

- Wooden barrels are laid on their sides. Bungholes are drilled into the top side and plugged with stoppers. Holes are also drilled into the ends of the barrels.

- The alcohol is poured into the barrel via long-necked funnels inserted into the bungholes. Mother of vinegar is added at this point. The barrel is filled to a level just below the holes on the ends. Netting or screens are placed over the holes to prevent insects from getting into the barrels.

- The filled barrels are allowed to sit for several months. The room temperature is kept at approximately 85°F (29°C). Samples are taken periodically by inserting a spigot into the side holes and drawing liquid off. When the alcohol has converted to vinegar, it is drawn off through the spigot. About 15% of the liquid is left in the barrel to blend with the next batch.

The submerged fermentation

method

- The submerged fermentation method is commonly used in the production of wine vinegars. Production plants are filled with large stainless steel tanks called acetators. The acetators are fitted with centrifugal pumps in the bottom that pump air bubbles into the tank in much the same way that an aquarium pump does.

- As the pump stirs the alcohol, acetozym nutrients are piped into the tank. The nutrients spur the growth of acetobacters on the oxygen bubbles. A heater in the tank keeps the temperature between 80 and 100°F (26-38°C).

- Within a matter of hours, the alcohol product has been converted into vinegar. The vinegar is piped from the acetators to a plate-and-frame filtering machine. The stainless steel plates press the alcohol through paper filters to remove any sediment, usually about 3% of the total product. The sediment is flushed into a drain while the filtered vinegar moves to the dilution station.

The generator method

- Distilled and industrial vinegars are often produced via the generator method. Tall oak vats are filled with vinegar-moistened beechwood shavings, charcoal, or grape pulp. The alcohol product is poured into the top of the vat and slowly drips down through the fillings.

- Oxygen is allowed into the vats in two ways. One is through bungholes that have been punched into the sides of the vats. The second is through the perforated bottoms of the vats. An air compressor blows air through the holes.

- When the alcohol product reaches the bottom of the vat, usually within in a span of several days to several weeks, it has converted to vinegar. It is poured off from the bottom of the vat into storage tanks. The vinegar produced in this method has a very high acetic acid content, often as high as 14%, and must be diluted with water to bring its acetic acid content to a range of 5-6%.

-

To produce distilled vinegar, the diluted liquid is poured into a boiler

and

brought to its boiling point. A vapor rises from the liquid and is collected in a condenser. It then cools and becomes liquid again. This liquid is then bottled as distilled vinegar.

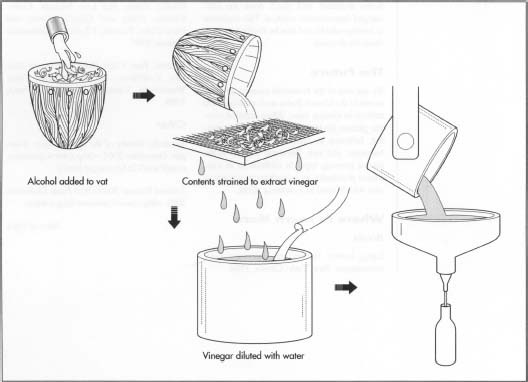

The production of vinegar.

The production of vinegar.

Bascsamic vinegar

- The production of balsamic vinegar most closely resembles the production of fine wine. In order to bear the name balsamic, the vinegar must be made from the juices of the Trebbiano and Lambrusco grapes. The juice is blended and boiled over a fire. It is then poured into barrels of oak, chestnut, cherry, mulberry, and ash.

- The juice is allowed to age, ferment, and condense for five years. At the beginning of each year, the aging liquid is mixed with younger vinegars and placed in a series of smaller barrels. The finished product absorbs aroma from the oak and color from the chestnut.

Quality Control

The growing of acetobacters, the bacteria that creates vinegar, requires vigilance. In the Orleans Method, bungholes must be checked routinely to ensure that insects have not penetrated the netting. In the generator method, great care is taken to keep the temperature inside the tanks in the 80-100°F range (26-38°C). Workers routinely check the thermostats on the tanks. Because a loss of electricity could kill the acetobacters within seconds, many vinegar plants have backup systems to produce electrical power in the event of a blackout.

Byproducts/Waste

Vinegar production results in very little by-products or waste. In fact, the alcohol product is often the by-product of other processes such as winemaking and baker's yeast.

Some sediment will result from the submerged fermentation method. This sediment is biodegradable and can be flushed down a drain for disposal.

The Future

By the end of the twentieth century, grocery stores in the United States were posting $200 million in vinegar sales. White distilled vinegar garners the largest percentage of the market, followed in order by cider, red wine, balsamic, and rice. Balsamic vinegar is the fastest growing type. In addition to its continued popularity as a condiment, vinegar is also widely used as a cleaning agent.

Where to Learn More

Books

Lang, Jenifer Harvey, ed. Larousse Gastronomique. New York: Crown, 1984.

Proulx, Annie, and Lew Nichols. Cider: Making, Using and Enjoying Sweet and Hard Cider. Pownat, VT: Storey Communications, 1997.

Watson, Ben. Cider Hard and Sweet: History, Traditions, and Making Your Own. Woodstock, Vermont: Countryman Press, 1999.

Other

Alcoholic Drinks of the Middle Ages: Vinegar. December 2001. < http://www.geocities.com/Paris/1265/cvinegar.html >.

Sonomna Vinegar Works Web Page. December 2001. < http://www.sonomavinegar.com >.

Mary McNulty

RACK,MUSHROOM UNIT,(THATCHED HOUSE)

PLEASE give me its notes with diagram..upto date.

thank u

Where I worked I made a mash containing between 10-12% whole grain alcohol, nutirents ( a sweet yeasty combo), and filtered water. I was making white vinegar. (The initial inoculation mash was about 4% alcohol, nutrients, and filtered water) maintain the temp and air and add your sleepy acetobacter. When the acetobacter get going consuming the alcohol the alcohol content will drop and athe acidity content will increase. DO NOT LET THEM CONSUME ALL THE ALCOHOL! at about .05% discharge about 2/3 of the beginning amount and SLOWLY replace it with the 10-12% mash. The bacs will be consuming while the tank is charging so just do not let the total alcohol content increase more than 5%. (might kill your bacs)(Some bacs can take higher strengths but I am assuming you want to make 115-135 grain vinegar.) Once charge is complete wait, test and repeat. FYI Cider process times are much faster.Hope that was kinda helpful Joevie