Eyeglass Lens

Background

Eyeglass lenses are glass or plastic optical items that fit inside eyewear frames to enhance and/or correct the wearer's vision. The magnifying glass, invented in the early 1200s, was the first optical lens used for enhancing vision. Made from a transparent quartz and beryl lens, the invention revealed the critical discovery that reflective surfaces ground to certain angles could enhance vision. Following this invention, Alessando di Spina introduced eyewear to the general populace. Due to the increasing demand for eyewear, quartz and beryl lenses were virtually replaced by glass lenses. The convex lens was the first optical lens used in glasses to aid the correction of farsightedness, but other corrective lenses followed, including the concave lens for the correction of near-sightedness, and more complex lenses for the correction of astigmatism, as well as the invention of bifocals by Benjamin Franklin in 1784.

More than 80 percent of all eyeglasses worn today have plastic lenses, but plastic lenses have not always been the lens of choice. The glass lens remained dominant until 1952, when plastic lenses were introduced. The plastic lens rapidly grew in popularity because the lens was lighter and less prone to breakage. Today, the manufacture of plastic eyeglass lenses far exceeds the manufacture of glass lenses, but the process has remained much the same for both types. Plastic as well as glass lenses are produced by successive stages of fine grinding, polishing, and shaping. While the same process is used to produce lenses for telescopes, microscopes, binoculars, cameras, and various projectors, such lenses are usually larger and thicker and require greater precision and power. This article will focus on plastic eyeglass lenses.

In the past, opticians relied on separate optical laboratories to produce eyeglass lenses. Today, there are a number of full-service optical outlets that produce lenses for customers on-site. However, optical outlets do receive lens "blanks"—plastic pieces already formed to close-to-exact size with different curves ground into the front of the lens—from optical laboratories. Blanks with different curves are used for specific optical prescriptions.

Raw Materials

The plastic blanks received from optical laboratories are round pieces of plastic such as polycarbonate approximately. 75 inch (1.9 centimeters) thick or thicker and similar in size to eyeglass frames, though slightly larger. Most finished eyeglass lenses are ground to at least. 25 inch (.63 centimeter), but this thickness may vary depending upon the particular optical prescription or "power" required. Other materials used to produce eyeglass lenses are:

- Adhesive tape

- A liquid with a lead alloy base

- Metal

- Dyes and tints

Design

Eyeglass lenses are designed in a variety of shapes to match eyeglass frames. The thickness and contour of each lens will vary

Convex and concave lenses, known as spherical lenses, require one ground curve per lens, while more curves are required to correct astigmatism. The degree and angle of the curve or curves in a lens determines its optical strength.

Various lens treatments and tints are added after the lenses are shaped but before they are inserted in frames. The coatings are added by dipping the lenses into heated metal bins filled with the treatment or tint. The treatments and tints available include various sunglass tints and colors, ultraviolet light tints, durability and impact-resistant treatments, and scratch-resistant treatments. Among the latest advances in tints is the light-sensitive tint, which combines the advantages of regular clear lenses with the protection of sunglasses. These lenses adjust to the amount of sunlight being radiated, thus providing sun protection when needed.

Various grades of plastic are used for eye wear, but the most popular is the "Feather-weight," an impact-resistant polycarbonate plastic. This type of plastic lens is more durable and 30 percent thinner and lighter than regular plastic lenses. It is also the more expensive lens. Other lens types include the standard "CR 39" trade name plastic lens—CR 39 is a monomer plastic—and the "High Index" plastic lens, which is 20 percent thinner and lighter than ordinary plastic lenses.

The Manufacturing

Process

The following procedure assumes the plastic lenses are being made at an optical laboratory.

- 1 The optical laboratory technician inputs the optical prescription for a pair of plastic lenses in the laboratory's computer. The computer then provides a printout specifying more information necessary for producing the required prescription.

-

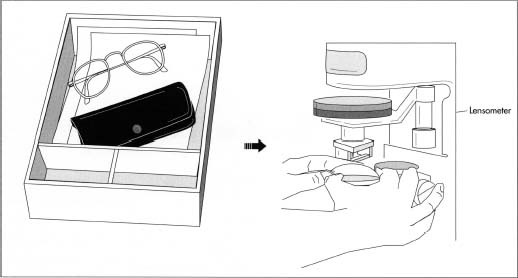

2 Based on this information, the technician selects the appropriate

plastic lens blanks. Each blank is placed in a prescription tray along

with the customer's eyeglass frames and the original work order.

The prescription tray will remain with the technician throughout the

production process.

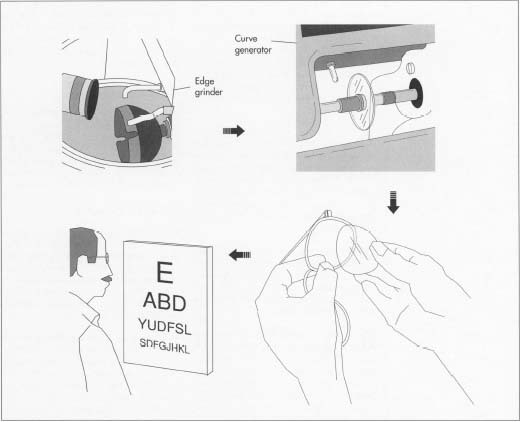

Although the appropriate curves have already been ground into the front of the lens, the technician must still grind curves into the back of the lens. This is done in a curve generator. After polishing the lenses, they are put in an edge grinder, which grinds each lens to its proper shape and places a bevel around the edge so that the lens will fit the eyeglass frames. Following any necessary tint applications, the lens are put into the frames.

Although the appropriate curves have already been ground into the front of the lens, the technician must still grind curves into the back of the lens. This is done in a curve generator. After polishing the lenses, they are put in an edge grinder, which grinds each lens to its proper shape and places a bevel around the edge so that the lens will fit the eyeglass frames. Following any necessary tint applications, the lens are put into the frames.The plastic blanks have different curves already ground into the front of them; therefore, the technician must select the blank that corresponds to the optical prescription required for each lens. The rest of the optical prescription, or power, must be ground into the back of the lens.

Blocking

- 3 The technician places the lenses in a lensometer, an instrument used to locate and mark the "optical center"—the point that should be centered over the customer's pupil—of the lens blanks. Next, adhesive tape is affixed to the front of each blank to keep the front from being scratched during the "blocking" process. The technician then places one lens blank at a time in a "blocker" machine, which contains a heated lead alloy that fuses the block to the front of the blank. The blocks are used to hold each lens in place during the grinding and polishing processes.

- 4 Next, the technician places each blank into a generator, a grinding machine that is set for the optical prescription. The generator grinds the appropriate optical curves into the back of each lens. After this step, the lenses must be "fined," or polished.

Polishing

- 5 The technician selects a metal lens lap —a mold corresponding to the required optical prescription of the lens, and both lenses are placed in the fining machine with the back of each lens in the appropriate lap. The front of each lens is then polished in a series of fining operations. First, each lens is rubbed against an abrasive fining pad made of soft sandpaper. After a second fining pad made of a smooth plastic is placed over the original sandpaper pad, the lens is polished again, as the fining machine rotates the pads in a circular motion while water flows over the lenses. After the initial fining process is completed, the two pads are peeled off and thrown away.

- 6 Next, the laps are removed from each lens and soaked in hot water for a few moments. The laps are then attached back on the lenses and placed in the fining machine, where the third and final fining pad is attached. The fining machine rotates the pads in a circular motion while a polishing compound consisting of aluminum oxide, water, and polymers flows over the lenses.

- 7 The lenses are removed from the fining machine, and the block attached to each lens is gently detached with a small hammer. Then, the tape is removed from each lens by hand. The laps are sterilized before they are used to hold other lenses.

- 8 Each lens is marked "L" or "R" with a red grease pencil, indicating which is the left and right lens. After the lenses are again placed in the lensometer to check and mark the optical center and inspect the other curves necessary for the proper optical prescription, a leap pad —a small, round metal holder—is then affixed to the back of each lens.

Beveling

- 9 Next, the technician selects the lens pattern that matches the shape of the eyeglass frames and inserts the pattern and the lenses into an edging machine. The machine grinds each lens to its proper shape and places a bevel around the edge of the lens so that the lens will fit the eyeglass frames. Water flows over the lens throughout this process.

- 10 If the lenses require additional grinding, the process is done by hand using a mounted power grinder. This step is necessary for lenses to be inserted in metal or rimless frames, which require more precise bevels.

- 11 Finally, the lenses are dipped into the I desired treatment or tint container. After drying, the eyeglass lenses are ready for insertion in the desired frames. The optical laboratory may send the lenses back to the optical outlet without the frames, in which case the optical outlet will insert the lenses in the frames.

Byproducts

Byproducts or waste from the manufacturing process include plastic dust or fine shavings and a liquid polishing compound consisting of aluminum oxide, water, and polymers. The waste material is placed in metal bins for 48 hours along with sanitation compounds (vermiculite of cat litter) before disposal.

Quality Control

Plastic eyeglass lenses must meet rigid standards set by the American National Standards Institute and the Food and Drug Administration (FDA). In addition, all licensed optical laboratories belong to the National Optical Association, which requires strict adherence to prescribed guidelines regarding quality and safety.

Throughout the normal production process, plastic lenses undergo four basic inspections. Three of these inspections occur in the laboratory and the fourth occurs at the optical outlet before the eyeglasses are given to a customer. Other periodic inspections may also be advised. The four inspections involve checking the optical prescription prior to the production process and verifying the optical center placement; visually checking lenses for scratches, chips, rough edges, or other blemishes; visually checking the optical prescription before the lenses are viewed in the lensometer, and verifying optics while the lenses are in the lensometer; and measuring and verifying frame alignment with a ruler.

Where To Learn More

Books

Impact Resistant Lenses: Questions and Answers. U.S. Department of Health and Human Services, 1987.

Periodicals and Pamphlets

"High-Speed Spindles Aid in Fabricating Plastic Eyeglass Frames with Special Finishes." Plastics Design & Processing. December 1983/January 1984, p. 21.

How Your Eyeglasses Are Made. Optical Laboratories Association.

Krasnow, Stefanie. "Athletic Specs: The Eyes Have It." Sport. August, 1987, p. 97.

More Than Meets the Eye. Optical Laboratories Association.

"Plastic Beats Acrylic for Lenses." Design News. August 18, 1986, p. 29.

— Greg Ling

thank you

Im not sure I have a good idea of exactly what your asking, but hopefully this will clear up your question. If you wear bifocal lenses currently, you shouldn't need to remove them in order to read things in you near vision. If you are wearing bifocals and your near vision is a bit fuzzy or unclear, perhaps it's time to update your prescription? If you can read a book up-close, generally about 14 - 17inches from your face, without squinting and without extending your arms in order to focus in better then you should have no need for the bifocals in the first place.

Finally, if you are not wearing bifocals and only wear glasses to correct your distance vision, and you are finding it difficult to see things clearly up-close, your Optometrist should be able to adjust you prescription, i.e. bifocals etc., and correct this issue.

To answer your question technically, it really all depends on your distance vision prescription. The lenses in your glasses have curves cut into them. Think of a perfectly round basketball. If it is perfectly round, drawing a straight line from one point to another anywhere on the ball will have the same arc, or curve measurement. If we apply this thinking to the back of the lenses in your glasses we can follow the same logic. If your prescription reads:

-2.00 -1.00 X 050

-1.00 $

then the top set of numbers is for your right eye and the bottom is for your left. The first number for the right eye (-2.00) is called the Sphere power. This number is a measurement of the arc or the curve that has been cut into every axis on the back side of your lens. This number generally is adjusted to correct the shape of your eye ball. I know that sounds a bit weird, but you can understand that when light enters the eyeball of a person who's eyeball may not be as round as it should be and instead might be bit more oblong like a football, this light hits the retina at a different angle than it should and results in unclear vision.

The second number for the right eye (-1.00) is called the cylinder power. This corrects any astigmatism you might have. Having an astigmatism just means that your cornea(the very front part of your eye) maybe isn't as round as it should be, and this is what is causing the light to fall on the retina differently than it should. This type of correction has to be more precise. This is the reason for the third number in the prescription for the right eye (050). This tells us that at every axis on the back of your right lens, a -2.00 curve has been cut. But on the 050 or 50th axis, a -1.00 curve cut into the lens. If made properly, and if you are fitted properly when you select your glasses, these two curves should cross directly over your pupil and correct your vision.

Having a bifocal with this prescription just means adding the necessary magnification to the overall prescription. Adding a +1.00 add power or bifocal to this prescription only changes the sphere power and does so algebraically. So if your right eye is -2.00 -1.00 X 050 with a bifocal add power of +1.00, then in the bifocal portion of your lens, the actual prescription would be -1.00 -1.00 X 050.

The bottom number I gave assumes no astigmatism and only gives a Sphere power. A bifocal with a +1.00 add power essentially removes the prescription from the lower portion of the left lens, removing any correction. So yes, there are ways to remove, or a better word would be balance, the prescription by using an add power that brings your lenses back to zero in the reading portion. This cannot be done with every prescription, but it will for some.

Hope I didn't confuse you. Have a good day.