Screw

Background

Screws are part of a family of threaded fasteners that includes bolts and studs as well as specialized screws like carpenter's wood screws and the automotive cap screw. The threads (or grooves) can run right handed or left, tapered, straight, or parallel. There are two types of screws, machine and wood screws. Both are made of metal, however the machine screw has a constant diameter and joins with nuts while the wood screw is tapered and grips to the actual wood surface.

History

Even though the concept of the screw dates back to around 200 B.C. , the actual metal screw that is known today was not developed until the Renaissance. Early screws had to be handmade, so no two screws were ever alike. The time consuming process of hand filing the threads into the screw form made mass production and use virtually impossible. In 1586, the introduction of the first screw-cutting machine by Jacques Besson, court engineer for Charles IX of France, paved the way for more innovations.

Inspired by earlier designers and makers of scientific instruments like microscopes, clockmakers and gunsmiths led the way in screw-cutting machine design. In 1760, Job and William Wyatt, two English brothers, filed a patent for the first automatic screw-cutting device. Their machine could cut 10 screws per minute and was considered one of the precursors to mass production machinery.

During the early nineteenth century, Englishman Henry Maudslay produced the method of screw manufacture still in use today. His machine was the first power-driven, screw-cutting lathe. In the United States, at the same time, David Wilkinson also built a screw-cutting lathe and was awarded the first American screw patent. New innovations followed soon after. In 1845, Stephen Finch developed a turret lathe, and soon after the Civil War, Christopher Walker invented a fully automatic lathe.

The first screw factory, Abom and Jackson, was opened in Rhode Island in 1810. By 1895 screw makers in America were forming unions and demanding a minimum wage of $1.75 per ten-hour day for a member and $1.25 for an apprentice. Smaller scale innovations continued to be made to improve efficiency. John E. Sweet devised the angular thread-cutting method to cut an entire thread from one side.

Today, machining of screws has been superseded by thread rolling. In 1836, American William Keane developed the thread rolling process, but at the time it had little success. The iron metal that was used to create the thread-rolled screws was too low grade and had the tendency to split during the die-cutting process. The eventual need to mass produce screws at a fraction of the cost of machining led to the reevaluation and establishment of the thread-rolling manufacture of screws.

Raw Materials

Screws are generally made from low to medium carbon steel wire, but other tough and inexpensive metals may be substituted, such as stainless steel, brass, nickel alloys, or aluminum alloy. Quality of the metal used is of utmost importance in order to avoid

Design

On a single thread screw, the lead and pitch are identical, lead is twice the pitch on a double thread model, and three times as much on a triple thread. The pitch of a screw is the distance between two threads (or grooves) from the same point on each thread. It is also more commonly known as the number of threads per inch or centimeter. The lead of the screw measures how far it is driven in for each revolution.

The Manufacturing

Process

Machining is only used on unique designs or with screws too small to be made any other way. The machining process is exact, but too time consuming, wasteful, and expensive. The bulk of all screws are mass manufactured using the thread rolling method, and that is the procedure described in further detail.

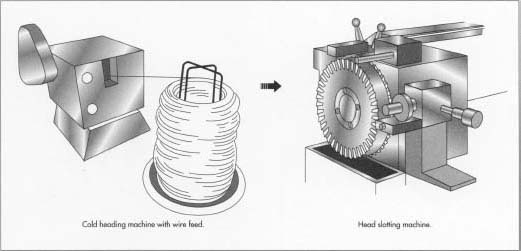

Cold heading

- 1 Wire is fed from a mechanical coil through a prestraightening machine. The straightened wire flows directly into a machine that automatically cuts the wire at a designated length and die cuts the head of the screw blank into a preprogrammed shape. The heading machine utilizes either an open or closed die that either requires one punch or two punches to create the screw head. The closed (or solid) die creates a more accurate screw blank. On average, the cold heading machine produces 100 to 550 screw blanks per minute.

Thread rolling

- 2 Once cold headed, the screw blanks are automatically fed to the thread-cutting dies from a vibrating hopper. The hopper guides the screw blanks down a chute to the dies, while making sure they are in the correct feed position.

-

3 The blank is then cut using one of three techniques. In the

reciprocating die, two flat dies are used to cut the screw thread. One

die is stationary, while the other moves in a reciprocating manner, and

the screw blank is rolled between the two. When a centerless cylindrical

die is used, the screw blank is rolled between two to three round dies

in order to create the finished thread. The final method of thread

rolling is the planetary rotary die process. It holds the screw blank

stationary, while several die-cutting machines roll around the blank.

Threads can be cut into the blank by several methods. In the reciprocal method, the screw blank is rolled between two dies. In the cylindrical method, it is turned in the center of several rollers.

Threads can be cut into the blank by several methods. In the reciprocal method, the screw blank is rolled between two dies. In the cylindrical method, it is turned in the center of several rollers. - All three methods create higher quality screws than the machine-cut variety. This is because the thread is not literally cut into the blank during the thread-rolling process, rather it is impressed into the blank. Thus, no metal material is lost, and weakness in the metal is avoided. The threads are also more precisely positioned. The more productive of the thread-rolling techniques is by far the planetary rotary die, which creates screws at a speed of 60 to 2,000 parts per minute.

Quality Control

The National Screw Thread Commission established a standard for screw threads in 1928 for interchangeability. This was followed by an international Declaration of Accord in 1948, adopting a Unified Screw Thread system. The standards focus on three main elements: the number of threads per inch, the designated pitch and shape of the thread, and designated diameter sizes. In 1966, the International Standards Organization (ISO) suggested a universal restriction on threads to ISO metric and inch size ranges with coarse and fine pitches. Compliance with the ISO suggested standards has been global.

Where to Learn More

Books

Brittania Company. Screws and Screw-Making. James H. Wood, 1892.

Camm, F. J. Screw Cutting. Cassell and Company Ltd., 1920.

Glover, David. Screws. Rigby Education, 1997.

Periodicals

Koepfer, Chris. "Technology Gamble Pays Off." Modern Machine Shop, February 1995, pp. 94-104.

— Jennifer Swift Kramer

Thank You,

Gene B. Mayfield

Lucerne Valley, Ca