Orange Juice

Background

Orange juice is defined in the United States Code of Federal Regulations as the "unfermented juice obtained from mature oranges of the species Citrus sinensis or of the citrus hybrid commonly called Ambersweet." True fresh squeezed juice is difficult to market commercially because it requires special processing to preserve it. Orange juice is commonly marketed in three forms: as a frozen concentrate, which is diluted with water after purchase; as a reconstituted liquid, which has been concentrated and then diluted prior to sale; or as a single strength, unconcentrated beverage called NFC or Not From Concentrate. The latter two types are also known as Ready To Drink (RTD) juices.

Citrus fruits, like oranges, have been cultivated for the last 4,000 years in southern China and Southeast Asia. One variety, the citron, was carried to the Middle East some-time between 400 and 600 B.C. Arab traders transported oranges to eastern Africa and the Middle East sometime between 100 and 700 A.D. , and during the Arab occupation of Spain, citrus fruits first arrived in southern Europe. From there, they were carried to the New World by explorers where they spread to Florida and Brazil by the sixteenth century. By the 1800s, citrus fruits achieved worldwide distribution. In the 1890s, the demand for them greatly increased because physicians discovered that drinking the juice of oranges or other citrus fruits could prevent scurvy, a vitamin deficiency disease.

The popularity of orange juice dramatically increased again with the development of the commercial orange juice industry in the late 1920s. In its early days, the juice industry primarily relied on salvaged fruit, which was unsuitable for regular consumption because it was misshapen, badly colored or blemished. In the 1930s, development of porcelain-lined cans and advances in pasteurization techniques led to improved juice quality and the industry expanded significantly. Then, in 1944, scientists found a way to concentrate fruit juice in a vacuum and freeze it without destroying the flavor or vitamin content. Frozen concentrated juices were first sold in the United States during 1945-46, and they became widely available and popular. After World War II, most Americans stopped squeezing their own juice and concentrated juice became the predominant form. With the increase in home refrigerators, frozen concentrate became even more popular. The demand for frozen juices had a profound impact on the citrus industry and spurred the growth of the Florida citrus groves. Frozen concentrates remained the most popular form until 1985 when reconstituted and NFC juices first out-sold the frozen type. In 1995, NFC juices were responsible for 37% of the North American market. This is in comparison to reconstituted juice, which held about 39% of the market. Today, commercial aseptic packaging allows RTD juices to be marketed without refrigerated storage. The current worldwide market for orange juice is more than $2.3 billion with the biggest area being the United States followed by Canada, Western Europe, and Japan.

Raw Materials

Fruit

The primary ingredient in orange juice is, of course, oranges. Oranges are members of the rue family (Rutaceae), and citrus trees belong to the genus Citrus. Oranges, along with all citrus fruits, are a special type of berry botanists refer to as a hesperidium. Popular types of oranges include navel, Mandarin, and Valencia. A blend of different types of oranges is generally used to provide a specific flavor and to ensure freedom from bitterness. Selection of oranges for juice is made on the basis of a number of factors such as variety and maturity of the fruit. The fruit contains a number of natural materials that contribute to the overall flavor and consistency of the juice including water, sugars (primarily sucrose, fructose, and glucose), organic acids (primarily citric, malic, and tartaric), and flavor compounds (including various esters, alcohols, ketones, lactones, and hydrocarbons.)

Other additives

Preservatives such as sulfur dioxide or sodium benzoate are allowed by federal regulation in orange juice although the amounts are strictly controlled. Similarly, ascorbic acid, alpha tocopherol, EDTA, BHA, or BHT are used as antioxidants. Sweeteners may be added in the form of corn syrup, dextrose, honey, or even artificial sweeteners. More often, though, citric acid is added to provide tartness.

Manufacturers may also fortify juices with extra vitamins or supplemental nutrients such as vitamin C, and less commonly, vitamins A and E, and beta carotene. (Beta carotene is naturally present in oranges, but only to a small degree.) There is some concern about the stability of these added vitamins because they do not survive the heating process very well. Calcium in the form of tricalcium phosphate, is also frequently added to orange juice.

The Manufacturing

Process

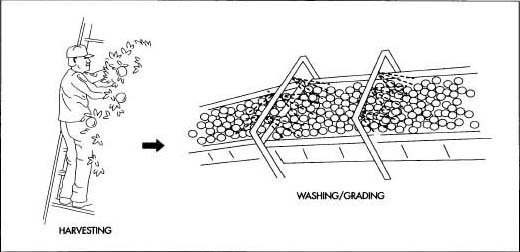

Harvesting/collection

- 1 Oranges are harvested from large groves. Some citrus growers are members of cooperative packing and marketing associations, while others are independent growers. When the mature fruit is ready to pick, a crew of pickers is sent in to pull the fruit off the trees. The collected fruit is sent to packing centers where it is boxed for sale as whole fruit, or sent to plants for juice processing. The oranges are generally shipped via truck to juice extraction facilities, where they are unloaded by a gravity feed onto a conveyor belt that transports the fruit to a storage bin.

Cleaning/Grading

- 2 The fruit must be inspected and graded before it can be used. An inspector takes a 39.7 lb (18 kg) sample to analyze in order to make sure the fruit meets maturity requirements for processing. The certified fruit is then transported along a conveyor belt where it is washed with a detergent as it passes over roller brushes. This process removes debris and dirt and reduces the number of microbes. The fruit is rinsed and dried. Graders remove bad fruit as it passes over the rollers and the remaining quality pieces are automatically segregated by size prior to extraction. Proper size is critical for the extraction process.

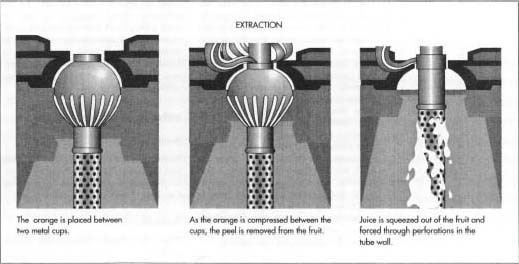

Extraction

-

3 Proper juice extraction is important to optimize the efficiency of the

juice production process as well as the quality of the finished drink.

The latter is true because oranges have thick peels, which contain

bitter resins that must be carefully separated to avoid tainting the

sweeter juice. There are two automated extraction methods commonly used

by the industry. The first places the fruit between two metal cups with

sharpened metal tubes at their base. The upper cup descends and the

fingers on each cup mesh to express the juice as the tubes cut holes in

the top and bottom of the fruit. The fruit solids are compressed into

the bottom tube between the two plugs of peel while the juice is forced

out through perforations in the tube wall. At the same time, a water

spray washes away the oil from the peel. This oil is reclaimed for later

use.

The second type of extraction has the oranges cut in half before the juice is removed. The fruits are sliced as they pass by a stationary knife and the halves are then picked up by rubber suction cups and moved against plastic serrated reamers. The rotating reamers express the juice as the orange halves travel around the conveyor line.

Some of the peel oil may be removed prior to extraction by needles which prick the skin, thereby releasing the oil which is washed away. Modern extraction equipment of this type can slice, ream, and eject a peel in about 3 seconds. When the mature fruit is ready to pick, a crew of pickers pull the fruit off the trees. Once collected, the fruit is sent to plants for juice processing. Before extraction, the fruit is cleaned and graded.

When the mature fruit is ready to pick, a crew of pickers pull the fruit off the trees. Once collected, the fruit is sent to plants for juice processing. Before extraction, the fruit is cleaned and graded. - 4 The extracted juice is filtered through a stainless steel screen before it is ready for the next stage. At this point, the juice can be chilled or concentrated if it is intended for a reconstituted beverage. If a NFC type, it may be pasteurized.

Concentration

- 5 Concentrated juice extract is approximately five times more concentrated than squeezed juice. Diluted with water, it is used to make frozen juice and many RTD beverages. Concentration is useful because it extends the shelf life of the juice and makes storage and shipping more economical. Juice is commonly concentrated with a piece of equipment known as a Thermally Accelerated Short-Time Evaporator, or TASTE for short. TASTE uses steam to heat the juice under vacuum and force water to be evaporated. Concentrated juice is discharged to a vacuum flash cooler, which reduces the product temperature to about 55.4° F (13° C). A newer concentration process requires minimal heat treatment and is used commercially in Japan. The pulp is separated from the juice by ultra-filtration and pasteurized. The clarified juice containing the volatile flavorings is concentrated at 50° F (10° C) by reverse osmosis and the concentrate and the pulp are recombined to produce the appropriate juice concentration. The flavor of this concentrate has been judged to be superior to what is commercially available in the United States and is close to fresh juice. Juice concentrate is then stored in refrigerated stainless steel bulk tanks until is ready to be packaged or reconstituted.

Reconstitution

- 6 When the juice processor is ready to prepare a commercial package for retail sale, concentrate is pulled from several storage batches and blended with water to achieve the desired sugar to acid ratio, color, and flavor. This step must be carefully controlled because during the concentration process much of the juice's flavor may be lost. Proper blending of juice concentrate and other flavor fractions is necessary to ensure the final juice product achieves a high quality flavor.

Pasteurization

-

7 Thanks to its low pH (about 4), orange juice has some natural

protection from

bacteria, yeast, and mold growth. However, pasteurization is still required to further retard spoilage. Pasteurization also inactivates certain enzymes which cause the pulp to separate from the juice, resulting in an aesthetically undesirably beverage. This enzyme related clarification is one of the reasons why fresh squeezed juice has a shelf life of only a few hours. Flash pasteurization minimizes flavor changes from heat treatment and is recommended for premium quality products. Several pasteurization methods are commercially used. One common method passes juice through a tube next to a plate heat exchanger, so the juice is heated without direct contact with the heating surface. Another method uses hot, pasteurized juice to preheat incoming unpasteurized juice. The preheated juice is further heated with steam or hot water to the pasteurization temperature. Typically, reaching a temperature of 185-201.2° F (85-94° C) for about 30 seconds is adequate to reduce the microbe count and prepare the juice for filling.

In an automated process, the juice is extracted from the orange while the peel is removed in one step.

In an automated process, the juice is extracted from the orange while the peel is removed in one step.

Packaging/filling

- 8 To ensure sterility, the pasteurized juice should be filled while still hot. Where possible, metal or glass bottles and cans can be preheated. Packaging which can not withstand high temperatures (e.g., aseptic, multilayer plastic juice boxes which don't require refrigeration) must be filled in a sterile environment. Instead of heat, hydrogen peroxide or another approved sterilizing agent may be used prior to filling. In any case, the empty packages are fed down a conveyor belt to liquid filling machinery, which is fed juice from bulk storage tanks. The filling head meters the precise amount of product into the container, and depending on the design of the package, it may immediately invert to sterilize the lid. After filling, the containers are cooled as fast as possible. Orange juice packaged in this manner has a shelf life of 6-8 months at room temperature.

Byproducts/Waste

Byproducts from orange juice production come from the rind and pulp that is created as waste. Products made with these materials include dehydrated feed for livestock, pectin for use in making jellies, citric acid, essential oils, molasses, and candied peel. Certain fractions of orange oil (known as d-limonene), have excellent solvent properties and are sold for use in industrial cleaners.

Quality Control

Quality is checked throughout the production process. Inspectors grade the fruit before the juice is extracted. After extraction and concentration, the product is checked to ensure it meets a number of USDA quality control standards. The most important measurement in orange juice production is the sugar level, which is measured in degrees Brix (percentages by weight of sugar in a solution). The types of oranges used and the climate in which they were grown effect the sugar level. Manufacturers blend juices with different sugar levels together to achieve a desired sugar balance. The final juice product is evaluated for a number of key parameters include acidity, citrus oil level, pulp level, pulp cell integrity, color, viscosity, microbiological contamination, mouth feel, and taste. A sensory panel is used to evaluate subjective qualities like flavor and texture. Lastly during the filling process, units are inspected to make sure they are filled and sealed appropriately.

The Future

Future processing improvements are likely to come from the use of computer controlled sizing and grading of fruit. Orange juice formulations will see changes as the trend toward adding more nutrition-oriented ingredients, such as antioxidants, continues. In addition, future formulas are likely to be blends of orange juice with other, more exotic, fruit flavors, like kiwi, or even vegetable juices, like carrot.

Where to Learn More

Books

Nelson, P.E. and D.K. Tressler, ed. Fruit and Vegetable Juice Processing Technology. Westport, Connecticut: AVI Publishing Co., 1980.

Periodicals

"Juice Up." Food Product Design (July 1997).

"Unconcentrated Effort." Food Processing (November 1996).

— Randy Schueller