Wooden Clog

Background

Wooden clogs are heavy work shoes that were typically worn by French and Dutch peasants up through the beginning of the twentieth century. Known in French as sabots, and in Dutch as klompen, these sturdy shoes protected the feet of agricultural workers from mud and wet and from injury by the sharp tools used in the field. French clogs were often made from a combination of wood and leather. However, the classic Dutch clog is entirely wooden. Wooden clogs are naturally highly water resistant, and therefore they were especially useful in the marshy fields of the Netherlands. Farm workers also wore specially decorated wooden clogs to church and on holidays. In World War I, entrenched soldiers wore wood and leather clogs called sabotines. Up through this time, clogs were typically made by hand.

Later, industrialization made leather and rubber shoes more readily available, and wooden clogs became less wide-spread. However wooden clogs are still worn by Dutch farm workers, and also by Dutch fishermen and steel factory workers. Clogs made a resurgence in the 1960s across Europe and North America, not as a work shoe but as fashion. They are still popular in the 1990s. These modern clogs are usually a leather shoe attached to a wood sole. Clogs made entirely from rubber are also popular as gardening shoes.

Raw Materials

Wooden clogs are usually made from one of three kinds of wood: European willow, yellow poplar, or tulip poplar. These woods are all hard and water resistant. After the lumber is cut, it is not treated in any way, but made into shoes as soon after felling as is practical. No other material is necessary to make wooden clogs, though some shoes are varnished or decorated with paint.

The Manufacturing

Process

Wooden clogs were traditionally made entirely by hand, either by their wearers or by specialized artisans. The shoes were roughly carved on the outside, then clamped into a bench that held them vertically, toe down. Then the artisan scooped them out with a long-handled tool. Less than a hundred years ago, a wooden clog factory might consist of dozens of workers making shoes in this same manner, by hand. The introduction of automated machines sped up the process, though machines still required attentive operators.

Making the blanks

- 1 The willow or poplar trees are felled and sawn into logs. The logs are debarked, then fed into a saw, which cuts them into rough rectangular blocks. Each block, called a blank, will be formed into one shoe. The size of the block varies depending on what size shoe is to be made out of it. For a men's size 8 shoe, the block might be 14.5 x 5.25 x 5.25 in (37 x 13.3 x 13.3 cm).

Shaping

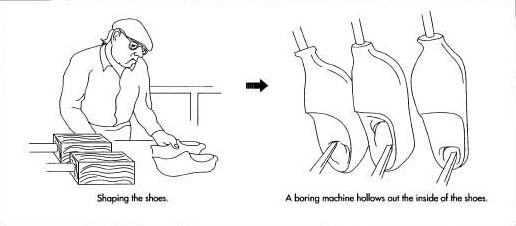

-

2 Two blanks are placed into a machine called a shaper (also known as a

copier or duplicator). This shapes the outside of the shoes. Next to the

blanks is a vinyl shoe, which is used as a pattern. Each shoe size has

its own vinyl pattern, and the machine operator locks the appropriate

pattern into

the shaper. A pointer is set to ride along the pattern shoe. Attached to the pointer are two electrically powered cutting tools. These are set to the right and left shoe blanks. The machine operator turns the power on, and carefully traces the outline of the pattern shoe with the tracer. The cutting tools follow the motion of the tracer, and carve out the out-line of the shoe. The two blanks rotate in opposite directions, allowing a left and a right shoe to be carved simultaneously.

Carving the interior

- 3 Next, the carved blanks are placed in another machine called a dual action borer. This machine has a three-pronged cutting implement. The center prong is a tracer, and this goes inside another vinyl pattern shoe. The right and left prongs are set to the right and left shoe blanks. Their cutting ends are sharp-edged scoops similar to ice cream scoops or melon ballers. The operator holds a long metal rod attached to the tracer prong, and pushes this along the inside of the pattern shoe. The cutters follow the tracer's movement, and scoop out the wood blocks. This machine carves out the interior of the shoes to its approximate finished dimensions, leaving an extra 0.25 in (0.64 cm) of material all around.

Refining

- 4 The shoes are placed in a similar machine called a refiner, which is in this case entirely automatic. Two cutters follow a pointer on a vinyl pattern and scoop out the inside of the shoes, trimming away the excess 0.25 in (0.64 cm) of material left by the previous step. The fine action of this machine leaves the interior of the shoes extremely smooth, and they need very little finishing after this point.

Drying

- 5 The shoes are left to air-dry for four to six weeks. They may be simply placed in a dry storeroom, or they may set in a low temperature furnace, which circulates warm dry air around them. As they cure, moisture is drawn out of the wood, and the shoes harden.

Finishing

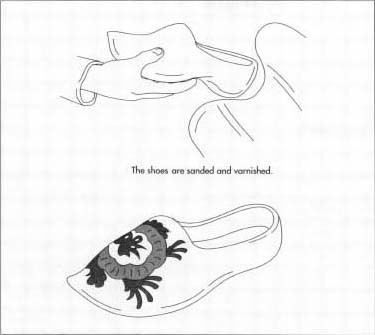

- 6 After the shoes are completely dry, workers sand them lightly inside and out. At this point the shoes are completely finished and ready to wear. If the shoes are to be decorated, they are painted or varnished after sanding.

Where to Learn More

Books

Rowland, Della. A World of Shoes. Chicago: Contemporary Books, 1989.

Yue, Charlotte. Shoes: Their History in Words and Pictures. New York: Houghton-Mifflin, 1997.

Periodicals

Chargot, Patricia. "Clompin' Around." Detroit Free Press (March 23, 1998).

Kuniholm, Erin. "Going Dutch: Wearing Clogs Is the Next Best Thing to Going Barefoot." Women's Sports and Fitness (October 1997): 82-84.

— Angela Woodward