Popsicle

Background

The sound of an ice cream truck is a delight to the ears of children and adults alike on a hot summer day. That truck carries delicious concoctions that the industry calls collectively "frozen novelties." And it is guaranteed to carry a variety of frozen pops—ices, sherbets, pops in push tubes, and pops on sticks—in fruit flavors and colorful shapes and sizes. These are often called popsicles after the brand-named frozen pop.

History

The frozen pop has its origins in frozen desserts that are as old as civilization. The ancient Romans had blocks of ice carried down from the mountains in the summer. The blocks were ground into crushed ice that was flavored with fruit and syrup. The Chinese are credited with the same practice, and these sherbets, sorbets, and frozen ices were served in the thirteenth century court of Kublai Khan (1215-1294) when the Italian adventurer Marco Polo (1254-1324) visited. Other ancient cultures including those of Turkey, Persia (now Iran), the Arabian Peninsula, and India also knew of frozen, flavored ices. They were usually a privilege of the wealthy and were made of ice, fruit pulp, fruit syrup, and flowers for flavor, fragrance, and color. Frozen treats were served to honor guests at banquets or to cleanse the palate between courses, as sorbets are still used today.

In the sixteenth century, Catherine de Medicis (1519-1589), the Italian-born wife of French King Henry 11 (1519-1559), brought recipes for frozen ices from Italy and introduced the concept of freezing the ices artificially by plunging their containers into icy brine. The next major landmark in the development of frozen novelties occurred in three capital cities—Paris, London, and New York—in the 1820s. Street vendors sold ice cream and penny ices (frozen ice dollops, rather like small snow cones) that were held on tiny glass goblets. The customer bought an ice for a penny and ate it directly from the goblet (without any spoon or stick), and the vendor recycled the goblet for the next customer.

The little scoops of frozen ice or ice cream were called "hokeypokey" (probably derived from an Italian catchphrase), and the pennyice men were also called hokeypokey men. The hokeypokey men were the original Good Humor men, named for the brand of ice cream on a stick that was introduced in 1922. Good Humor grew out of two popular inventions. The automobile (and the truck) helped vendors cover a larger area and carry more novelties than the street vendors with their push carts. And, in 1910, lollipops had become a popular candy for children in America and England. Ice cream on a stick and the Good Humor bar followed. Meanwhile, another icy revolution was underway.

The discovery of the frozen pop is attributed to an 11-year-old boy. In 1905, Frank Epperson mixed powdered soda pop and water but forgot about his preparation and left it outside on the porch of his home in Oakland, California. The concoction froze overnight, and the stick he had used to stir the powder in the water stuck in the frozen liquid. Frank pulled out the whole frozen mass and found that he had invented a new treat. He named it the "Epperson icicle." The following summer, he made his frozen treats in his family's icebox and sold them around his neighborhood under the shortened name of "Epsicle." Frank again rechristened his discovery the "popsicle" to show that they were made from soda pop. The selling price for the original Epsicles was five cents a piece. Epperson patented his treat in 1924 when he was 30 years old as the Popsicle.

From 1920 through the mid-1970s, Good Humor trucks sold all varieties of frozen treats until the cost of gasoline and insurance overwhelmed profits. Independent vendors still sell frozen treats in many neighborhoods, but the large variety of popsicles in grocery stores makes the household refrigerator the most familiar pop "vendor" today.

Raw Materials

The two principal kinds of non-dairy frozen treats manufactured are the popsicle and the juice bar. The popsicle is 90% water. Its other ingredients are sugar, corn syrup, gum, and stabilizers. These ingredients give the popsicle a texture called "mouth feel" that makes it pleasant to eaten. The sugars and stabilizers cause the pop to soften in the air so it is edible, instead of melting and dripping like an ice cube. Flavoring is highly concentrated and is usually some traditional fruit flavor and color. Specialty firms manufacture the flavorings and apply the chemistry needed for true flavor and color when the flavoring is reconstituted. Some flavors, particularly citrus, also have additives like citric acid that gives the flavor its citrus "bite." Juice bars have the same ingredients except that concentrated fruit juice provides the color and flavor. All other frozen treats (like fudge bars) are dairy products.

Popsicle makers also need sticks for the handles and printed wrappers. These are supplied by outside sources. The popsicle manufacturer will commission a design for the printing on the wrapper, which is etched on a plate and used to print the wrappers. Wrappers are purchased by the truckload, so a new product is a major cost commitment. Sticks are made of basswood by specialized subcontractors. Sometimes the sticks are also printed with jokes, funny sayings, or designs; they are bought by the pallet-load in quantities sufficient to last the manufacturing season.

Design

Design of a popsicle consists of a combination of color, flavor, and shape of the pop. Flavors and colors tend to stay in a range of traditionally accepted fruit flavors. Molds can be made in almost any shape and can also be filled in stages to create layered colors or be coated with outer colors and flavors for contrast. The molds are made in a precision design process, however, and are very expensive—about $60,000 for each design. The decision to make a new mold is a major one for all popsicle makers. When the costs of modifying nutritional information, printing new wrappers, and advertising are added in, each new product may mean an investment of $100,000. Large manufacturers may produce up to 30 new items per year.

The Manufacturing Process

-

The popsicle begins with making water ice in sets of sterilized vats.

The vats are refrigerated to 35-37°F (1.7-2.8°C). The base

material, consisting of sugar, corn syrup, stabilizers, and gum, is

mixed with water and then subdivided into several separate vats where

the flavoring and coloring are added. The formulas for the mixes are

constant, but trained inspectors flavor-test the batches and adjust

flavorings and other ingredients to taste. In the refrigerated vats, the

fluid becomes water ice—it does not quite reach the point of

freezing and still can be pumped easily.

The water ice is pumped to a million-dollar machine called a Vita-Line. The machine is circular and about 15 ft (4.6 m) in diameter and transports sets of molds through several processes to form the pops. The machine is made of stainless steel and supports 200 to 300 strips of molds. Each strip may be 6, 8, or 12 molds wide, 4-8 ft (1.2-2.4 m) wide, and 30-40 ft (9-12 m) long. A typical popsicle machine will generate 4,320 pops per hour; larger machines produce twice as many, and a production line may include five machines.

A continuous chain across the top of the machine and around the wheel moves the molds through the process. All fluids are pumped by electrically powered pumps. Pneumatics (air pressure) control the movements of slave cylinders and the opening and closing of valves in a simple sequence of motions. In the first set of steps, the molds are pre-rinsed, washed, rinsed again,

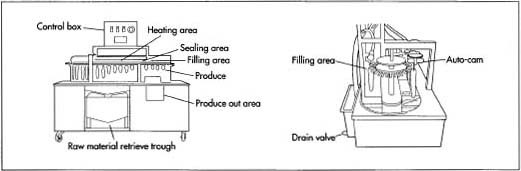

and sanitized (heated) in a minute-long process. The machine inverts the molds so that a spray bar can pre-rinse any materials out of the molds. Two wash bars, above and below the molds, wash and rinse the molds in a fresh water rinse. Another bar sanitizes the molds. Two types of popsicle filling and sealing machines.

Two types of popsicle filling and sealing machines. - After washing, the molds are reinverted so they can be filled. The flavored water ice is pumped through sets of nipples into the molds, and the molds are pulled into a tank filled with water containing calcium chloride (salt brine) that is ammonia-cooled to-25--30°F (-32--34°C). As the molds are drawn along the 20-ft (6-m) length of the tank, their contents pass from the liquid to frozen state. If several different layers of flavors make up the particular pop, hoppers with different fluids are attached to the same machine that makes single-flavor pops. The first fill is injected, the mold is partially submerged in salt brine to freeze it, and a vacuum pump sucks out any remaining liquid on the frozen surface. During the second fill, the second flavor is added, flash-frozen, and sucked dry of standing water; finally, the third fill is added. Midway through the process, the water ice is partially frozen. At this stage, pops designed to have a twisted appearance are given that twist, and an injector pushes the sticks into the pops, which freeze from the outside toward the center so the frozen outside supports the stick. In the last 3 or 4 ft (0.9 or 1.2 m) of the machine, the centers of the pops freeze.

-

The molds then pass briefly through a tank containing 180°F (68°C) water that slightly heats the molds. An overhead extractor pulls the pops out of their molds by their sticks. If the pops are to be dipped to make an outside coating on them, the extractor lowers them into a dip tank, and the coating is flash frozen. The extractor bar then carries the popsicles to the bagging area where the bags are blown open by bursts of air as the pops are dropped by the extractor. They fall by gravity into the waiting bags.

The bagged pops ride on a conveyor along an assembly line where workers snap open boxes, fill the boxes with bagged pops, tape the boxes closed, and pack sets of boxes into a larger set called a master pack. The master packs are taken to the freezer where they are stored until shipment. In an alternative wrapping process, popsicles are dropped by the extractor bar on sheets of mylar or glassine paper that has been preprinted. The wrapping machine shapes the wrapper around each bar, seals the top and bottom, and cuts off the excess paper at both ends.

Quality Control

Quality control includes taste and visual tests. The water ice is "taste-tested" even though the mixture has been made precisely. The tester is usually an expert who knows when the flavor is not quite up to company standards despite the perfect measurements of the ingredients. The tester has the authority to adjust the mixture to the right taste.

The processes of the Vita-Line that are watched especially closely are the fill process, the extraction of the pops from the molds, and the dropping of the pops into the bags. As the pops are boxed, the assembly workers can reject any pops that look suspicious, so quality control in the popsicle factory is a "hands-on" activity. Smaller companies benefit from this approach because they share a family atmosphere and pride in their product.

Byproducts/Waste

There are no byproducts or waste from the process of making water ice. Some waste water containing sugar may result from the steps in rinsing the molds, but the water is simply transported as waste water through the city's water treatment system—that is, no special treatment is required.

Major safety issues in the factory include the refrigeration process in which liquid ammonia must be handled. Low-pressure steam is used in cleaning and sanitizing the molds and machinery, and, of course, electricity supplies the power. Workers are trained in the operation of machines, so safe practices are ingrained and safety becomes a minimal concern.

The Future

The future of the popsicle will follow the demands of the public. Tastes lean toward traditional flavors and colors, so the refining and improving of traditional products is a primary interest among popsicle makers. Experts calculate that 100 ice pop flavors have been produced in the 75 years since the creation of the Epsicle, but cherry, orange, and grape are still the favorite flavors among the estimated 3 million popsicles sold every year. "Boutique" flavors such as daiquiri or huckleberry are made to catch the fancy of adventurous tastes, and combinations of types of pops like ice cream bars with an ice coating or popsicles with a small quantity of ice cream in the mixture are ways of producing new products that do not stray too far from tradition but appeal to consumers undecided between dairy and non-dairy novelties.

Manufacturers also watch their competitors, but small companies cannot match the investment needed for new sets of molds (for example) that may not be big sellers. Each new item also requires new labels with correct nutritional information that conforms to government labeling requirements and other details, and that can be very expensive. Cost does not seem to impede the popsicle's future, however; 98 new novelties were introduced in 1998, not counting the pop called "Frosty Paws," which was made for dogs. The future of popsicles relies on tradition rather than rapidly changing fads. A long, hot summer is the popsicle's best marketing tool.

Where to Learn More

Books

Dickson, Paul. The Great American Ice Cream Book. New York: Atheneum, 1972.

Liddell, Caroline, and Robin Weir. Frozen Desserts. New York: St. Martin's Press, 1995.

Wardlaw, Lee. We All Scream for Ice Cream. New York: Harper Trophy, Harper-Collins Publishers, Inc., 2000.

Wulffson, Don L. The Kid Who Invented the Popsicle: And Other Surprising Stories About Inventions. New York: Penguin Putnam Books for Young Readers, 1997.

Periodicals

Belleranti, Shirley W. "A treat from Marco Polo." Hopscotch 8, no. 2 (August-September 1996): 9.

Onoe, Phil. "At Large and At Small." American Scholar 67, no. 4 (1998).

Ward, Carol J. G. "Try frozen Popsicle treats to cool down this summer." Knight-Ridder Newspapers (August 10, 1999).

Other

Ching Tan Machinery Works, Taiwan. http://www.foodmachine.com.tw/e/d.htm (June 29, 2000).

Good Humor-Breyers Ice Cream. http://www.icecreamusa.com (June 29, 2000).

The Ice Screamer. P.O. Box 465, Warrington, PA 18976. http://www.icescreamers.com (June 29, 2000).

Perry's Ice Cream. http://perrysicecream.com . (June 29, 2000).

Popsicle Zone. http://www.popsicle.com (June 29, 2000).

Waukesha Cherry-Burrell Ice Cream. http://www.gowcb.com/products/IceCream/freezeindex.htm (June 29, 2000).

— Gillian S. Holmes

Ive also always had a question:

How did Epperson get the stick to stay in the middle and freeze? I mean, I know it was an accedent, but I would think it would have fell to the side when he set it in there if he was not holding it up.

That never made sense to me.

Anyway, good info and very informative! Really helped me with my science project!