Spam

Background

Spam is a brand name for a canned meat product containing ham, pork, salt, flavorings, and preservatives that are mixed and cooked under vacuum pressure. There are other brands of similar canned pork meat products, but Spam—made by Hormel Foods Corporation—is the original and the best-selling of the brands.

The standard Spam can is brick-shaped and holds 7 oz (198 g) of meat. A 2-oz (57-g) serving contains 170 calories, provides 7 g of protein, 140 calories of fat, and has 0.75 g of sodium. It contains small amounts of cholesterol and iron. Americans eat approximately 3.8 cans per second. Two American plants produce 44,000 cans of Spam every hour. Hawaii consumes the most Spam in the world—about four million cans yearly (it is particularly popular in sushi).

Spam is an important protein source and economical as well. Unopened cans require no refrigeration and Spam has an indefinite shelf life because it is heat-sealed within the tin. It can, therefore, be shipped all over the world without spoiling. Thus, it is an important food source in many places where fresh meat is difficult to obtain or expensive (such as Hawaii and Guam). Spam has become a kitschy favorite with Spam t-shirts and cookbooks selling quite well. Spam has also made it onto the worldwide web with several websites dedicated to the product. The term spam has also come to mean unwanted junk e-mails received on personal computers.

History

Spam was first released onto the American market in 1937. Jay Hormel, the son of a successful Minnesota meat-packing house owner, was an energetic young man with big plans for his father's company. Hormel brought out canned ham in 1926. When his product was imitated, Hormel added spices to make it distinct. In the early 1930s, many companies were producing canned pork in large containers. Hormel's competition included lips, snouts, even ears in their meats but Hormel refused to use these refuse parts. Instead, he used the shoulder of the pig (a cut of meat rarely used because of its time-consuming removal from the bone). Hormel's meat was superior and more expensive than the competition's, but once opened it was indistinguishable. Hormel sought a way to seperate his product from the rest, and he decided to try two things: reduce the size of the can so it was family-sized and design a distinctive label.

Hormel's first experimental 12-oz (340-g) cans of this pork luncheon meat turned out to be 8 oz (227 g) of meat and 4 oz (113 g) of useless juice. As the heat cooked the meat in the sealed can, cells broke down and released an excessive amount of juice. Hormel tried many things to reduce the juice. Ultimately he discovering that it was not enough to put it in a can that was vacuum sealed, but the meat must also be mixed in a vacuum in order to minimize the juice released while cooking.

The new luncheon meat was not available for a while, awaiting a marketable name and an iconic label. After much dispute, the name Spam seemed perfect. Most believe it to be a combination of the words spiced and ham, but the original product contained no ham. (Hormel later added ham to the mixture because so many thought it was already in the product.) Upon release the meat was not an instant seller, but Spam was touted for its value and convenience.

By 1941, 40 million cans of Spam had been sold. During World War II, Spam was sent overseas to feed American G.I.s. Hormel supplied Allied troops with 15 million cans of Spam per week throughout the war. World leaders—including Eisenhower, Margaret Thatcher, and Nikita Khrushchev—credited Spam for its effectiveness. After the war, Hormel actively advertised the product, getting big names to sing its praises. Plants overseas also began producing Spam. By 1959, Hormel had manufactured its billionth can. By 1962, the 12-oz (340-g) can was joined by a 7-oz (198-g) can for single people and small families. Other innovations included Spam with cheese chunks and smoke-flavored product (1972) and Spam-Lite (1992). A major re-design of the label occurred in 1997, and both the old and new version entered the Smithsonian.

Raw Materials

The primary ingredient in Spam is chopped pork shoulder meat mixed with ham. About 90% of Spam is pork from a pig's shoulders. The remaining 10% (or so) comes from the pig's buttock and thigh, better known as ham. This ratio varies according to ham and pork prices. The U.S. Department of Agriculture does not permit any nonmeat fillers in lunchmeat, nor does it allow pig snouts, lips, or ears. The second ingredient is salt, added for flavor and for use as a preservative. Also, a small amount of water is used to bind all ingredients together. Sugar is also included for flavor. Finally, sodium nitrate is added to prevent botulism and acts as a preservative as well. It is the sodium nitrite that gives Spam its bright pink color—without it, Spam would discolor and become brown.

The Manufacturing Process

- Pigs are no longer butchered by the Hormel Company, so meat is purchased from dealers and brought into the plant. Pork shoulders and ham are brought into the plant and cut apart. The pork shoulders are put into a powerful hydraulic press that literally squeezes the meat off the bone. The deboned meat is put into a large gondola or basket. Ham, however, must be cut away from the bone by hand. The meat-cutters remove and sort the meat from the shanks in the ham trim lines. The whitest, fattiest pieces are put into a large gondola marked "white," while meatier pieces are hand-sorted into one marked "red." The gondolas remain in a refrigerated area until they are needed.

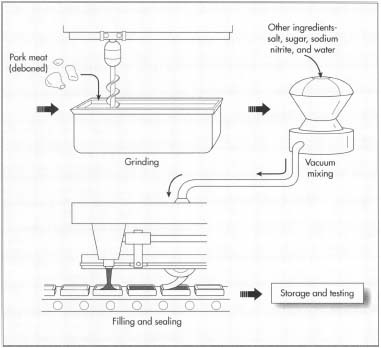

- Next, the gondolas are wheeled from the cold storage area and onto the main floor. The meat is transferred to a crane-like machine and then dumped into a large metal trough equipped with a drill bit. There, the drill bit thoroughly grinds the red and white pieces dumped in the trough. The batch is weighed (usually about 8,000 lb [3,628 kg] at this point) and passed under a metal detector (to catch a stray knife or mixing component). A small sample of Spam is analyzed to ensure it has the right combination of pork to ham and white to red pieces.

- The ground meat is then distributed by the gondolas into several vacuum mixers. When these mixers are in the open position, they look like giant gas grills, but they are equipped with a refrigerated ammonia outer core that brings the meat temperature down to below freezing (32°F [0°C]). Then, the other ingredients in Spam—salt, sugar, water, and sodium nitrite—are added. The mixer lid is closed, creating an airtight seal, and the batch is mixed. The reason the vacuum is induced, the meat chilled, and the salt added is to reduce the amount of juice released by the meat when it is cooked. If too much liquid is released during cooking, the can would contain a large amount of gelatin.

- While the Spam is being mixed, machines elsewhere are pushing empty, upside-down Spam cans off storage pallets one layer at a time. The plain silver cans are pushed onto a conveyor belt and sent toward the filler.

-

Nearly 1,000 lb (454 kg) of Spam is manually unloaded from the first

mixer, dumped into receivers, and fed through pipes. The mixture moves

through the pipes until it reaches the cone-shaped can fillers. As the

cans travel undeneath the fillers, a device picks each one up and

deposits the raw, ground Spam into the can (from the

bottom) in one motion. The can is filled as the machine lifts it.

Spam is a mixture of ground pork meats, seasonings, and other ingredients that have been cooked under vacuum pressure.

Spam is a mixture of ground pork meats, seasonings, and other ingredients that have been cooked under vacuum pressure. - The can is sealed at a closing machine. They are then stamped with an identifying code so that the product can be traced back to the manufacturer.

- Now, the closed cans head to the six-story-tall hydrostatic cooker. Spam is cooked in the can by very hot water within the cooker. The cans approach to cooker in a line, an arm swings out and pushes 24 cans onto a shelf. The shelf moves upward, and an arm swings out an pushes another group of cans onto a shelf. In two hours, 66,000 thousand cans will travel up and down 11 chambers in this huge cooker as they are heated, sterilized, washed, and cooled.

- As the cans leave the hydrostatic cooker, they are now cool and ready for labeling. The labels sit at the end of the cooker in long rolls. An automatic labeler attaches a polypropelene film label on each can, and the labeler cuts the label to the correct length.

- The cans are now ready for boxing. Twenty-four cans are fed onto flat pieces of cardboard, and a box is formed around the cans using the cardboard. The boxes are moved, and when a palette is filled with boxes, the entire pallet is shrink-wrapped. The cans are stamped with a date and other identifying numbers. A huge robot crane, driven by computer, transfers the pallet to a rack of shelving in the building. When the pallets get to the loading dock, then they are hoisted into the shelves by machines.

- The Spam cans cannot be shipped out for 10 days. One of every 1,000 cans produced must undergo extensive testing to make certain the meat was properly cooked. If there are no problems, the cans may be sold.

Quality Control

Hormel would likely agree that Spam begins with quality pork and ham. Hornel no longer supplies its own meat for Spam, but the company chooses the meat carefully. Meat-cutters who cut the meat from the ham carefully perform their tasks and throw the pieces into the appropriate gondola. Also, the huge hydrostatic cooker has an alarm that trips if the computer detects there is any problem with the batch. The workers must fix that problem within three minutes. If they don't, the entire batch's viability is in question.

Portions of each batch are examined to make sure the batch has the right amount of pork shoulder to ham. The U.S. Department of Agriculture does not permit any Spam cans to leave the processing plant for 10 days. One out of every 1,000 cans be subjected to a 100°F (38°C) test to see if the can bulges or shows any other signs of improper cooking. The bacteria content is also tested. Finally, taste tests are routine at Hormel Foods Corporation. Every Friday all executives involved in Spam production meet to visually inspect (and sometimes taste) several different batches of Spam produced during the week.

The Future

Since Spam was first released it has undergone many transformations. From plain Spam to Turkey Spam to Spam-Lite. People are coming up with endless recipes that call for Spam, and Hormel is trying to incorporate every consumer's need into their product development. Spam with less sodium is now available. The launch of Hormel's website dedicated to Spain now provides consumers with a catalog devoted to Spam and Spam labeled products.

Where to Learn More

Books

Wyman, Carol. Spam: A Biography. San Diego: Harcourt, Brace & Co., 1999.

Other

"Spam: An Authorized Biography." A Manual for Public Relations. Hormel Foods, 2000.

— Nancy E.V. Bryk

Many Thanks