Pacifier

Background

A pacifier is a form of an artificial nipple on which the baby or child sucks. Fluids do no pass through the pacifier, rather, the action of sucking on the nipple is thought to soothe or calm the baby, quieting the baby, and even alleviating the burning and itching of the gums during teething.

Pacifiers generally have three parts: the nipple; the guard, which rests on the baby's lips; and the ring attached at the center of the guard. Artificial nipples are always made of a material that closely simulates a mother's nipple. It is usually of latex or silicone and is occasionally of hard plastic. The guard is firmly attached to the nipple and prevents ingestion of the nipple by the child. Increasingly, pacifier manufacturers believe that the nipple and mouth guard should be of one material and molded together so that the two do not have to be fused during the manufacturing process. There is evidence that when the pacifier is made of two pieces it is at greater risk for failing at that juncture and creating a potential choking hazard. This guard must have holes in it to ensure that in the event of ingesting the guard the holes permit air to pass through to the windpipe. Finally, the ring at the center of the guard must be present in order to pull the pacifier forcibly from the mouth in the event of ingestion.

Manufacturers of pacifiers must comply with extensive government regulations developed to prevent pacifier failures from choking infants and young children. Pacifiers made in the United States must undergo testing to ensure that they comply with these regulations. Even with these regulations pacifiers are occasionally recalled because of product failure. Manufacturers must test each new pacifier design extensively before production, and then keep compliance reports on hand in the event that the information is requested at any time.

History

The early history of pacifiers is inextricably bound to the development and use of the baby rattle. The two were often attached to both amuse and assuage a crying baby. Rattles were used for centuries by primitive adults for ceremonial and musical or dance use and could be of sticks, teeth, shells or pods. In addition, primitive man used rattles with bells to ward off evil spirits and even children wore bells. Romans gave children peony wood bead necklaces that were pulled into the baby's mouth for teething and to ward off illness. Such soothing bead necklaces were used for many centuries. Some rattles were constructed with a handle that had inserted into it a smooth piece of stone or bone that was used for the baby to suck upon and teethe. This end of the rattle was known as the gum stick and could be made of rock crystal, ivory, agate, carnelian, mother-of-pearl, bone, or coral, all of which felt cool upon the gums.

Coral was one of the most effective materials thought to protect children from spirits as well as witchcraft, enchantment, and epilepsy. Coral necklaces were given to babies at birth for this reason. (In some cultures a coral necklace is still an appropriate baby gift.) It did not take long to combine the coral and rattling bells into a single baby toy that was often referred to as coral and bells. These devices had a branch of coral at one end and a metal shank with bells attached at the other end. The coral was sucked on, and being fairly soft and knobby, could soothe the baby and rub against sore gums as the bells sounded and warded off evil spirits. Fairly expensive coral and bells were generally crafted by silver or goldsmiths and offered for sale in the Colonies by 1700. Sticks of cane sugar or candy were given to babies to suck upon as well. Less expensive rattles used for sucking included gum sticks of wood with small vegetable gourds or wicker or willow rattles that could be put into the mouth. The baby's own fingers or fists have been the pacifier of choice for many babies as well.

When the sap from rubber trees was viably used in manufacture of household products by the middle of the nineteenth century, nipples for nursing bottles and simple soothers were devised. In the twentieth century, with better refinement of rubber and associated materials, many companies entered into the pacifier market. Hard plastics and silicone molders produced the product without much regulation. However, the United States Consumer Product and Safety Commission soon saw catastrophic failure with unregulated two-piece and hard plastic pacifiers and has since extensively regulated the industry.

Raw Materials

Pacifiers are manufactured from a soft, pliable material that closely resembles a mother's nipple. Increasingly, doctors and safety experts are urging manufacturers to produce pacifiers as a single unit, of one material, that cannot separate and pose a choking hazard. Thus, the product is preferably molded from a single material. In 2001, pacifiers are primarily constructed from either latex or silicone, although other soft plastics can be used in their manufacture. Unfortunately, manufacturers are finding that softening these other plastics requires chemical additives that have proven to be harmful to small children, and pacifiers have been recalled by the federal government not for failures of construction but because harmful additives were used in the processing of the raw materials.

Latex is technically referred to as natural rubber latex and is produced by the rubber tree Hevea brasiliensis. The milky latex from this tree is harvested by tapping the tree. The sap oozes from the tree when it is scored, then collected and processed for manufacture of thousands of household products. Most of the latex trees tapped for sap are in Southeast Asia and South America. Chemicals are added to raw latex to increase elasticity and strength. Proteins are found in this natural material that have caused severe allergic reactions in some consumers. Most manufacturers are either eliminating latex from their products lines as a result, or are treating the latex to counteract the effect of these proteins on consumers. In addition, latex does not survive repeated "boil and cool tests" in which the product is boiled, cooled, and then assessed for its ability to retain shape and perform successfully. Latex disintegrates more quickly than other substances during these tests. This is of concern as pacifiers cannot be repeatedly boiled or washed for sterilization without risk of disintegration.

The raw material of choice for American pacifiers is silicone, more expensive than latex but of superior performance. Silicones are synthetic polymers that are relatively chemically inert, stable at high temperatures, and resist oxidation. Thus, silicone is able to survive the boil and cool cycle far better than latex and therefore superior for products requiring sterilization. Some pacifier manufacturers buy silicone that is "certified," meaning it is of a superior grade for use.

Design

The design of pacifiers is an extremely important part of its manufacture. The pacifier manufacturer's director of research gathers information that assists with schematic design. He or she looks for the latest information on babies' upper and lower mouth configuration, the role of the tongue in sucking, and how a mother's nipple works and feels during nursing. Some consult directly with medical professionals about what they believe babies need in a pacifier. When the information is gathered, the research department works with the manufacturing department to produce a pacifier that conforms to recommendations made as a result of research.

Of paramount importance is the research department's responsibility to stay on top of the United States Consumer Product Safety Commission's Requirements for Pacifiers. These guidelines spell out precisely the

The Manufacturing

Process

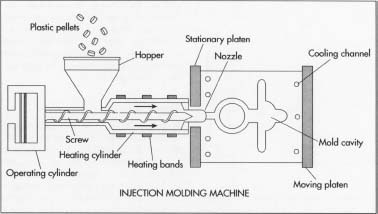

The manufacturing process for pacifiers is very simple. Since most are made of one-piece construction, the preferred method for safety's sake, the production occurs in one stage using liquid injection molding. Liquid injection molding was derived from metal die casting, but unlike molten metals, polymers have a high viscosity and cannot be poured into a mold. Instead, a large force must be used to inject the polymer into a hollow mold. A great deal of melt, the name given to molten polymers, must be forced into the cavity as there is some shrinkage upon cooling.

- First, the pellets of polymer must be melted at very high temperatures, usually 360-420°F (182-216°C). Pellets are fed from a hopper into a machine that liquefies the pellets. The polymer is now molten and ready for injection.

- Next, the melt is rammed into the mold at very high speed and under intense pressure, approximately 300-700 psi. The melt fills the mold, then a bit more melt is added in order to compensate for the contraction due to cooling and solidification of the polymer.

- Once the polymer has cooled, it is separated from the mold. This solidified part is simply ejected from the mold automatically, and the melt and injection cycle is ready to begin again. Each cycle takes between 10 and 100 seconds depending on the time it takes the polymer to cool and set.

- The one-piece pacifier is then inspected and packaged for shipment. Pacifiers are not considered sterile when packaged but are considered clean.

Quality Control

Perhaps the most important part of quality control happens at the very beginning and very end of the manufacturing process. First, the materials acquired for use in the product are often certified for cleanliness and to ensure that no unsafe chemicals are present. Then, prototypes are extensively tested to ensure the product complies to specifications set forth by the United States

Byproducts/Waste

When making silicone pacifiers there is little waste as the raw material is so expensive that the company seeks to re-use all flash or waste. In a mold with multiple cavities, the melt flows to each cavity using runners, which are long channels. The runners sometimes contain bits of polymer referred to as flash. If the runners are allowed to cool and solidify, the runners are separated from the part and must then be reground and transformed into pellets for reheating and melting. In hot runner molds, the runners are reheated and flow back into the system automatically. While the hot runner system virtually eliminates all waste, the mold system is very expensive.

The Future

Manufacturing pacifiers as a single unit device is the primary trend for the future. This design is preferred because it is less likely to pose a choking hazard for the child. Improvements in the types of raw materials used are also being researched. It is important that the rubber or plastic materials that become the pacifier do not contain harmful chemicals that could be transferred to the infant as it sucks on it.

Orthodontic problems often occur in children who use pacifiers for long periods of time and after they have developed their primary teeth. Research and development workers analyze the structure of children's mouths and their sucking patterns in order to develop pacifiers that will minimize the long-term effects of pacifier use.

Where to Learn More

Books

Henry Francis DuPont Winterthur Museum. Kids! 200 Years of Childhood. Hanover, New Hampshire: University Press of New England, 1999.

Weiss, Harry B. American Baby Rattles. Trenton, NJ: 1941.

Other

"Requirements for Pacifiers, 16 C.F.R. Part 1511." U.S. Product and Safety Commission Web Page. December 2001. < http://www.cpsc.gov >.

Oral interview with Paul Dailey, Director of Research and Development of Children's Medical Ventures, Inc. Norwell, MA. July 2001.

Nancy E.V. Bryk

Thanks.