Scale

Background

The traditional bathroom scale is used to measure a person's body weight. It is based on a spring system that uses the weight of the person to depress a lever, which in turn rotates a sprocket attached to the dial. The dial rotates until it stops, and a plastic marker marks the person's weight. A home-use bathroom scale has a margin of error of ±0.25 lb (±0.12 kg). Scales for bathrooms or kitchens are generally designed as spring balances.

History

Units of measurements have been used for all of antiquity. People have always used some type of set standard for trade. The first known measurement device was used by the Romans 2,000 years ago. They devised an equal beam scale which was shaped like the letter T with both arms measuring 7.4 in (18.8 cm) wide. Attached to each arm were metal pans that were typically 1.5 in (4 cm) in diameter.

The first known unit of weight was the wheat seed. The ancient Romans and Greeks used this standard to measure any other object against, generally for barter or trade. For instance, farmers would bring their crops to sell and they would be weighed against the known standard of wheat grain. X-amount of produce was equal to X-amount of grain needed to maintain the equilibrium of the balance. The Arabs improved on these techniques and established weight standards for gold, silver, and gems.

By the thirteenth century trade had become much more widespread, but people in different parts of the world (or even within the same country) used different standards of measurement. King Edward I of England established a base standard of measurement to which objects or materials could be compared to. This standard soon traveled through trade and became somewhat acceptable in other parts of the world.

In 1793, the French government devised a system based on a line running along the ground through Paris that measured the distance from the North Pole to the Equator. The French called this the metric system. People were unfamiliar with this system and it was not fully enforced until 1837 when it became the standard in European countries.

Scales themselves continued to evolve to meet both the distributor and customer's needs. Customer's wanted to be able to count on the accuracy of the distributor's scales to make sure that they were not being cheated. The first scales used a simple balance beam to weigh an object against a known standard.

The first spring balance was brought into widespread use in the eighteenth century. In Bilston, England Richard Salter began making what is today known as a fisherman's scale which used a spring balance to measure weight. The Salter brand was also the first company in England to marked bathroom scales. Modern home scales have evolved from these early industrial prototypes. Today, the scale is based on the same spring balance idea.

Raw Materials

The case of the spring scale is manufactured from stainless steel or aluminum. The interior is composed of metal springs, pins, gears, and plastic. The gears can be made from aluminum, copper, brass, bronze, stainless, steel, nickel silver, monel, zinc, iron, or plastic. The non-slip mat is formed from a mix of poly vinyl chloride and rubber.

Design

There are many different types of scales; solar, electronic, digital, and spring to name a few. The scales may also differ on what they measure. Some scales are able to measure a person's body fat ratio. The color and size of scales vary greatly to meet all customer needs.

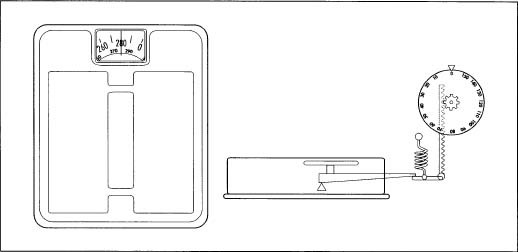

A typical spring scale is comprised of weight transmitting levers, a weight sensing mechanism, and dial enclosed in a metal casing. Generally, the scale is equipped with a non-slip pad on the platform so that the person does not slip and fall off the scale.

The Manufacturing

Process

- 1 Aluminum is melted until molten and then fed into a die that has the desired shape of the scale casing. The aluminum is cast in a cold chamber process at temperature of 1,202°F (650°C) so it will not bond with the steel die.

- 2 The aluminum is then cooled and ejected from the mold. Both the top and bottom of the scale body are manufactured using this process.

- 3 The top of the case is manufactured with a slot missing that will serve as the window through which to view the correct weight. This plastic covering is made from molted plastic fed into an injection molding machine. The plastic is then injected into a mold of the cover and left to cool. After cooling, the cover is removed and manually inserted into the top casing.

- 4 There are four levers used to distribute a person's weight through the scale. The levers are manufactured from thin sheets of aluminum or steel that is delivered to the plant. The sheets are then placed on a conveyor belt to be laser cut. A laser beam that is 0.008 in (0.2 mm) in diameter focuses 1,000-2,000 watts on the aluminum sheet. The laser gets the outline of the lever and instructions from a Computer Aided Drafting and Design (CAD) drawing.

- 5 The springs, brackets, and gears arrive preformed at the plant. They are inspected for quality and then distributed to work stations along an assembly line.

- 6 The dial is formed from a coining method. In this process the aluminum is placed in a set of dies that close, exerting up to 200,00 psi (1,375 mpa) depending on the level of detail on the dial.

- 7 The dial is then extracted and automatically painted, typically white with black numbers.

- 8 The non-slip pad is made from a mixture of polyvinyl chloride (PVC) and rubber. The resin is measured and mixed, then poured into the mold of the non-slip mat. The mold is then cured and the finished slip mat is removed.

Putting it all together

- 9 The case is then placed on a conveyor belt and the metal plate that holds the main lever and the spring is fitted through a slot that was molded into the side of the case.

- 10 The main lever that runs vertically through the middle of the scale is then rested upon the plate and hooked over the base of the casing.

- 11 The other levers are then hooked over the corners of the case bottom and hooked to the main lever.

- 12 The tooth rack and pinion are then manually connected to two compression springs.

- 13 Next, the metal dial is fixed to the main vertical lever. It rests on the rack and pinion system that will turn the dial based on the person's weight.

- 14 Four brackets that will secure the levers in place are connected to aluminum latches that were molded into the top cover of the scale.

-

15 The two halves of the case are then manually fitted together. The top

casing

is a little larger than the bottom, but will ensure a snug fit.

The inner mechanisms of a bathroom scale.

The inner mechanisms of a bathroom scale. - 16 The scale is tested for correct calibration. Then it is packaged and shipped to the distributor.

Quality Control

The parts used to manufacture the scale are checked for defects. Any defective parts that can be salvaged are removed and reused. Parts that are extremely damaged are discarded or recycled. The workers check the calibration of the scale against a known weight before it is packaged. Typically the scale should be able to detect weight within 0.25 lb (0.12 kg).

Byproducts/Waste

Any excess or defective parts are assessed for quality and then either reused or discarded.

The Future

As technology advances, so does the accuracy and application of scales. Today scales can measure not just weight but also body fat. These scales send a mild electrical current through the person's feet and up the rest of the body. The more quickly the signal travels through the body, the less fat. Software is also being developed that allows the scale to keep track of a person's weight loss or gain. Some are even able to track the weights of more than one person. These systems will be able to hook up to software on the home computer to better track weight loss or gain.

Where to Learn More

Other

Bodytrends.Com Web Page. December 2001. < http://www.bodytrends.com >.

ReallyFit.Com Web Page. December 2001.< http://www.reallyfit.com >.

Salter Scales Online. December 2001.< http://www.salterhousewares.com >.

Deirdre S. Blanchfield

It says in the article that the springs, brackets and gears arrive preformed at the manufacturing plant. I was just wondering whether you knew any company that supplies the preformed items or where I could go to find out this information?

Thanks

Fiona