Typewriter

Background

Typewriters fall into five classifications. The standard typewriter was the first kind manufactured. It was too heavy (15-25 lb or 5.6-9.3 kg) to move often, so it was kept on a desk or typing table. The standard typewriter had a wider platen (a rubber-covered, steel cylinder for absorbing typing impact) in the carriage (the part that moved the paper into place) that could hold oversized forms. The portable manual typewriter was smaller in size, lighter in weight, and equipped with a carrying case for easier movement and storage. Portable typewriters were popular for home and school use.

Electric typewriters were heavier than standard machines because of their motors and electrical parts. Electric machines made typing easier because less effort was needed to strike the keys. Electric portables were smaller and lighter than desktop machines, and they had carrying cases with storage for the power cord.

The most recent kind of typewriter to be produced—the electronic typewriter—eliminated many of the disadvantages of both standard and electric machines. Circuit boards made the electronic typewriter much lighter (about 10 lb or 3.7 kg) than other models. Personal word processors (PWPs) were closely related to computers.

History

Writing machines were built as early as the fourteenth century. The first patented writing machine was made in England in 1714 but never built. The first manufactured typewriter appeared in 1870 and was the invention of Malling Hansen. It was called the Hansen Writing Ball and used part of a sphere studded with keys mounted over a piece of paper on the body of the machine.

Christopher L. Sholes and Carlos Glidden developed a machine with a keyboard, a platen made of vulcanized rubber, and a wooden space bar. E. Remington & Sons purchased the rights and manufacture began in 1874. To avoid jamming typebars with adjacent and commonly used pairs of letters, Sholes and Glidden arranged the keyboard with these first six letters on the left of the top row and other letters distributed based on frequency of use. Their "QWERTY" system is still the standard for arranging letters.

The first Remington typewriter only printed capital letters, but a model made in 1878 used a shift key to raise and lower typebars. The shift key and double-character typeface produced twice as many characters without changing the number of typebars. By 1901, John Underwood was producing a machine that had a backspace, tab, and ribbon selector for raising and lowering the ribbon.

George Blickensderfer produced the first electric typewriter in 1902, but practical electric typewriters were not manufactured until about 1925. In 1961, International Business Machines (IBM) introduced the Selectric electric typewriter. From about 1960 to 1980, the standard typewriter industry in the United States withered away. The IBM Selectric II debuted in 1984, but IBM stopped making electric models in favor of the electronic Wheelwriter in the early 1990s. By this time personal computers were becoming more popular.

By the late 1990s, most of the manual typewriters supplied to the United States came from three firms. Olympia in Germany makes standard portables, Olivetti in Italy makes a standard office typewriter and two portable models, and the Indian firm Godrej & Boyce Manufacturing Company is the largest producer of manual typewriters.

Raw Materials

Carrying cases can be made of wood, steel, or plastic. Steel is the material used for most of the parts in standard models. Typewriters use hundreds to thousands of moving parts, and cold-rolled steel is one of the most reliable materials.

The platen is a steel tube covered with a rubber sleeve. The rubber sleeves are made of a special form of rubber from the "buna-N" family. Glue is used to adhere the rubber sleeve to the platen tube.

The keys were molded of plastic in a two-shot, injection-molding process that made white characters with the surrounding key tops in other colors. From the 1970s forward, a pad printing process has been used to apply the characters in ink and coat the keys with a durable "clearcoat" finish.

Mylar (plastic) ribbons with ink on one side are used to transfer the typeface. These ribbons are contained in plastic cartridges that could be thrown away.

Miscellaneous materials are also used. These include glue, paint, chemical solvents and other fluids, zinc and chromium for plating some components, and acetic acid for building protective coatings on some parts.

Design

Typewriters have several parts that allow them to produce typed papers; the keyboard being the most obvious. Each key is connected to a typebar that lifted a typeface to strike the paper. Each typeface has upper and lower case forms of a letter or numbers and symbols. The assemblage of typebars and typefaces is called the typebasket.

Mylar (a plastic produced in very thin ribbons and coated with ink on the platen side) typewriter ribbon uses ink to transfer images on the typeface to the paper. Its alignment parallels the platen and the paper, and ribbon guides raise the ribbon to print and then lowers it.

The platen stops the typeface but allows enough force to the paper for the image to print. The carriage is a box-like container in the upper, rear part of the typewriter that carries the platen, the lever for carriage returns and line spacing, guides to help direct and grip the paper, and the paper itself. The paper is inserted in a feed rack (paper support) in the back of the carriage, supported and curved up toward the typing surface in a paper table or paper trough, and held against the underside of the platen by two feed rollers.

An escapement (a device that allows motion in only one direction and in precise steps) controls the motion of the carriage to the left after each character was typed. A mainspring in the escapement transmits energy to move the carriage on ball bearings.

To move the paper up after a line of typing is complete, a line-spacing lever rotates the platen toward the rear of the typewriter. The lever is also the carriage-return that disengages the escapement and pushes the carriage back to the right for the new line. Knobs on the ends of the platen are turned so the paper can be removed.

The Manufacturing

Process

- 1 Metal (primarily pre-tempered steel) for typewriter parts arrives as round stock. Round stock is supplied in 10-12-ft-long (3-3.75-m-long) rods of steel, brass, or other metals and in a range of diameters for making screws, bolts, and rivets.

- 2 Rods of round stock are distributed to machines where fabricators mark and cut them to length for rivets, bolts, or screws. Screw machines (lathe-like devices) turn round stock into screws by cutting the threads, points, and heads. Hobs (another type of cutting tool) are often used to cut other fasteners to length and shape.

- 3 The parts are taken to plating or finishing stations where they are treated for protection from wear and rust. Zinc or chromium plating is applied by treating the metal parts in baths of non-metallic solutions that conduct electricity. The parts are subjected to slight electrical charges that cause atoms from small pieces of zinc or chromium to be attracted to them when the baths are given opposite charges. Electrically bonded coatings made up of thin layers of atoms of zinc or chromium protect all surfaces of the metal parts.

- 4 Parts of the typewriter on the inside of each machine are treated in a series of baths of acetic acid to color the metal black. This process of creating the black layer (called black oxide) is something like dyeing clothing; the general term for the process is bluing. After the acetic baths, the metal parts are bathed again in a dip tank containing a type of light oil. The hot oil dries and leaves a protective coating over the black oxide. These treatments protect the parts against rust.

- 5 At finishing stations, exterior parts are polished. Operators apply buffing compounds to buffing wheels on machines and hold the typewriter parts against them. The rotating wheels coat the parts with the compounds and shine the typewriter components. Workers polish very small parts by hand, also using polishing compounds and hand-held buffers.

- 6 Pieces are then riveted or brazed to form complete parts for assembly. Brazing is similar to a soldering process that uses alloys with lower melting temperatures than the metal pieces being joined to avoid melting or warping those pieces. Both brazing and riveting create rigid joins, although rivets are also used when parts have to be free to move. Screws, bolts, and other fasteners also make moveable connections.

- 7 The platen is a specialized subassembly because it requires precision grinding with heavy machinery and the process produces rubber dust. The internal steel tube (sometimes called the axle or shaft) is cut from hollow round stock. It is finished on the outside for easier addition of the rubber and on the ends for smoothness. Similarly, the internal metal rod is also cut from round steel stock. The centers are stamped from steel in sheet form.

- 8 A rubber sleeve is then heated slightly to fit over the platen, and an air press pushes the sleeve over the tube coated with glue. A rod and the two platen centers are added to the steel tube, and fittings are added to hold the rod and centers tightly.

- 9 To make the typefaces, blank pieces of metal called "type slugs" are formed in the machines by vibrating the slugs into die sets bearing the letters and other characters. As the slugs are worked into the dies and hardened, the typefaces are spit out of the machine. Then transferred to the subassembly section where they are soldered on the typebars.

- 10 The rail system uses ball bearings to glide the carriage from left to right. Subassembly of the carriage consists of mounting the rail to the base of the carriage, installing the ball bearings, and attaching the spring and linkages.

- 11 The carriage-return lever extends over the top of the typewriter. Although the it is attached to the carriage to move it, it also has several linkages to the platen, paper handling system, and escapement. The lever and one set of the ends of its linkages are connected to the carriage. The parts of the metal feed rack (also called a paper support) that hold the paper as it is put in the typewriter are assembled, and the rack is attached to the back of the carriage.

- 12 The paper-handling system is another subassembly. It includes the paper trough (also called a paper table), two feed rollers (like miniature platens) that holds the paper against the underside of the platen, the paper-release lever, and a paper-alignment scale (paper bail). The paper-handling system allows the paper to be inserted in the typewriter, held firmly during typing, and rolled out when the page is complete. The paper trough is a U-shaped piece of steel stamped out of sheet stock, curved, and plated.

-

13 The escapement's subassembly is a system of gears, small gears

called pinions, springs, chains, pawls, and fasteners. A pawl is a small

bar with a tooth at each end that drops into the teeth of a gear,

ratchet, or pinion. The pawls move the gear system forward, and the

gears advance the escapement rack that pulls the carriage of the

typewriter to each space needed for a new typed image. The escapement is

assembled

in a fitted, tray-like frame that will be set into the inner face of the strong underside of the typewriter jacket. This heavy underside and the arrangement of portions of other subassemblies that would be attached over the escapement protects the sensitive works.

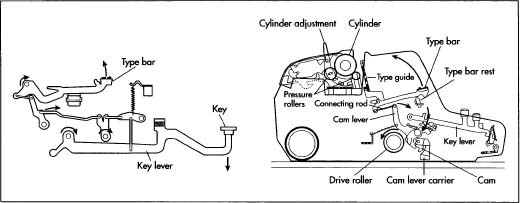

The inner mechanisms of a typewriter.

The inner mechanisms of a typewriter. - 14 The subassembly for the typebasket contains many of the 3,200-3,500 parts in the typewriter. The typebasket subassembly holds the typebars with typefaces on their ends as well as the spring system that connects the typebars to the keys. Each typeface is soldered to the end of its typebar. Each typebar has a unique angular bend so its typeface will strike flat against the platen. Like those in the carriage, sets of ball bearings are added to help move the typebars from upper to lower case and back. The assembler inserts the typebars in their positions in the typebasket and attaches the ends at the bottom of the basket to the appropriate springs. The springs will be connected to the keys when the keyboard and typebasket subassemblies are linked to each other during main assembly.

- 15 To begin the keyboard subassembly, the cap of each key is soldered to the correct key lever. The key levers are connected to springs that allow the keys to be depressed. The levers are put in appropriate slots in an internal keyboard frame. The spring system is also mounted to the keyboard frame to be connected with the springs for the typebasket subassembly during main assembly.

Main assembly

- 16 The five key subassemblies of the standard typewriter (the carriage, paper handling system, escapement, typebasket, and keyboard) are put on trucks and moved to the main assembly line where they are added to the typewriter frame.

- 17 Inside the body, the tray-like frame of the escapement is bolted into the inner face of the underside jacket of the typewriter.

- 18 The rail on the underside of the carriage is fixed to its matching half on the upper part of the body frame. The platen is set into place in openings in the carriage frame. A knob is added to the extruding end of the center rod on the right side of the platen; on the left end, a fitting holding the carriage-return and line-spacing lever is fitted on the rod, and is finished with another knob.

- 19 The keyboard and typebasket are inserted, their frames bolted to the body frame. A steel, V-notched typeguide is attached across the half-moon of the typebasket facing the platen; the V-notch provides an opening for the typefaces to strike the platen. The springs for each key and its typebar are linked together.

- 20 The typebars are also connected to the escapement and carriage linkages. To align typebars with the opening in the typeguide and strike the platen at the correct angles, the workers use three-pronged pliers to bend each typebar gently.

- 21 When the jacket of the typewriter is made from steel, it is attached to the main frame. The strong underside of the jacket had been installed on the main frame earlier because it also serves as a support for the escapement subassembly. Two pieces of steel forming lower sides of the jacket around the carriage are attached to the carriage frame. Two upper sides are also mounted on the carriage frame. These match the lower sides to provide round openings for the inner ends of the platen knobs so they can be used to turn the platen. The back and top L-shaped sections of the carriage jacket are attached to the body frame. The sides and top jacket of the keyboard are fastened in place over the keyboard. All of the sidepieces of the jacket are attached to the underside to strengthen the frame and jacket; the firm fit also seals the underside to limit the amount of dust that could enter the interior of the typewriter.

Quality Control

When raw materials are delivered to the typewriter fabrication plant, the receivers log in the materials and compare them to blueprints and specifications provided by design and manufacturing engineers. The quality control engineers also use a number of instruments for determining that parts and materials are acceptable such as verniers (short sliding rulers), micrometers (also called micrometer calipers) that are vice-like gauges for measuring thickness precisely, and height gauges to confirm dimensions.

When the typewriters are complete, a final quality control check is done by actually using each machine to test its performance. Each typewriter is checked for binding keys, print quality, advance of the ribbon, and movement of the carriage, among many other performance characteristics. Its appearance is careful examined for any flaws that might lead to rusting.

Byproducts/Waste

Most of the waste is generated during fabrication. Steel wastes such as the "skeletons" left after stamping or punch pressing and turnings and bushings (fragments) from screw-machine production of rivets and other parts are sold to salvage dealers, or melted and reused.

Plastic parts are used increasingly, plastic runners and rejected parts are also recycled. In the fabrication plant, they are reground, and these plastics were added to new batches of plastic. The percentage of reground plastic in a batch varied depends on the criticality of the part and the decision of the manufacturing engineers.

A large volume of rubber dust was produced when platens were ground round. The dust was carefully controlled and placed in collection boxes. The cooled dust was taken in the collection boxes to landfills. Machine exhaust was hooded to the outside. Minor quantities of other materials were disposed or recycled. Inked ribbons and cassettes containing Mylar ribbons were sometimes rejected and were also disposed in landfills.

The Future

Typewriters have a minor future in the Western World because computers have replaced them almost completely. Some businesses still need typewriters for limited uses, and many people find typewriters more convenient for single or small tasks.

Standard, electric, and electronic typewriters do have some future remaining in developing countries, and manufacturers in Asia and Europe supply this market. Brother makes typewriters in Japan, China has two or three factories, and Godrej & Boyce Manufacturing Company in India is the largest typewriter producer in the world. The Hermes, Olivetti, Olympia, and Royal brands are made in one or two factories in Europe. At the peak of standard typewriter manufacture, Smith Corona dominated production with a 54% market share; the company no longer makes its own typewriters, but, as a small supplier, it purchases them from a factory in Korea.

Rare use of typewriters today and their distinction as truly magnificent machines has made them popular and given them a respected future as collectibles. Antique dealers and other specialists buy and sell rare models on the Internet, and collectors exchange information using newsletters and web sites.

Where to Learn More

Books

Bryant, Carl. All About Typewriters and Adding Machines. New York: Hawthorn Books, Inc., 1973.

Davies, Margery. Woman's Place is at the Typewriter: Office Work and Office Workers 1870-1930. Philadelphia: Temple University Press, 1982.

Linoff, Victor M., ed. The Typewriter: An Illustrated History. Dover Publications, 2000.

Periodicals

Frazier, Ian. "Typewriter Man." The Atlantic Monthly Vol. 280, no. 5 (November 1997): 81-92.

Groer, Annie. "True to Type." The Washington Post (3 May 2001): HOI.

Other

"Typewriter History at a Glance." MyTypewritter.com Web Page. December 2001. < http://www.mytypewriter.com >.

Gillian S. Holmes

2,Standard typewriter

3.Standard long carriage typewriter