Cowboy Boots

Background

Traditional cowboy boots have narrow toes, high heels that slope under the foot, and leather tops that reach halfway up the shins. Designed for men who spent virtually their entire day in the saddle, cowboy boots are notoriously uncomfortable to walk in, and though adjustments have been made over the years, the boots remain unsuited for almost any work a cowboy or a rancher has to do on foot. Cowboy boots have also led a long double life as fashion accessories, beginning in the early 20th century, when Western life and work done on the open range were first mythologized in movies. Most cowboy boots that are manufactured now are not sold to people who will ever wear them on a horse, and the boots are valued more for the image they have acquired than the work they were originally intended to do.

History

In the 19th century, Anglo-Americans moving into the Southwest found people of Spanish descent already working the cattle that roamed the West Texas plains. Branding cattle and the practice of roping them from horseback were originally developed in Mexico, as was the basic design of what we now call the Western saddle. Though American settlers adopted many of their tools and methods, the Mexican vaqueros wore short, flat boots that were not well suited to the demands of their profession. Cowboy boots are direct descendants of the Northern European riding boot, and they may be the only contribution these settlers made to the essentially Spanish tradition of working cattle from horseback.

The Northern European riding boot was adapted for use on the range by German bootmakers who settled in Texas during the second half of the 19th century. The original German bootmakers designed a boot to meet the requirements of working in stirrups. Narrow toes made it easier for horsemen to put their feet in and out of stirrups while mounting and dismounting, and the high heel prevented the foot from slipping all the way through the stirrup and getting caught there. A foot caught in a stirrup could be especially dangerous if a cowboy were thrown out on the range, where he could be dragged for miles by a running horse. The length of the leather tops reduced chafing from stirrup leathers, and the boots also had high, reinforced arches, designed to make standing in the stirrups less strenuous. All of these features make the boots difficult to wear while working on the ground; they are particularly hard to run in, and when not on horseback many cowboys and ranchers today wear sneakers or a boot called a roper, with a round toe, a low heel, and a softer, more flexible sole.

Modern bootmakers divide into two categories: custom shops, where boots are made individually and much of the work is done by hand, and fully automated factories. The large industrialized companies, such as Tony Lama and Justin Industries, were originally family businesses that developed from smaller shops. The custom shops that remain in operation are often staffed by family members, and there the craftsmen are traditionally divided into "top men" and "bottom men." The former group cut, decorate, and assemble the

Raw Materials

The most widely used material for cowboy boots is calfskin, which is both easier to work with and more durable than cowhide. Most calfskins used in bootmaking actually come from Europe rather than the U.S., as few Americans eat veal and the skins of European calves are less likely to be scarred by brands or barbed wire. In the 1990s, however, changing eating habits have brought on a worldwide shortage of leather: fewer people are eating beef and so fewer cattle are being raised to any age. Though calfskin is the most common material, cowboy boots are also made from pigskin, horsehide, and kangaroo skin. For dress boots, bootmakers use a variety of exotic leathers including the skins of armadillos, ostriches, sharks, alligators, eels, lizards, and large snakes such as pythons.

The Manufacturing

Process

Cutting out the pieces

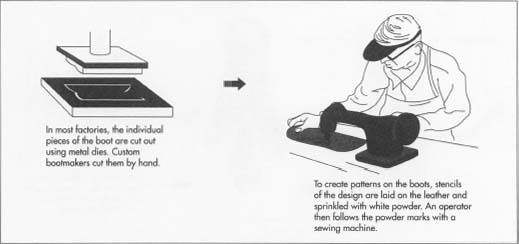

- 1 Once the leather has been selected, the process of making the top part of the boot begins by cutting out the individual pieces. This might be done by hand in custom shops, but in factories it is done by metal dies, which work like cookie cutters. The top of a boot consists of three parts: the part that covers the top of the foot, the part that encloses the back of the heel, and the part that fits around the bottom of the shins. These are called, respectively, the vamp, the counter, and the uppers. The vamp is like the top and sides of an ordinary man's shoe, but it is one piece instead of several, without lace holes and a separate tongue. The counter covers what the vamp does not. The uppers are cut in two pieces, one for the front and one for the back, designed to join each other at the sides. At this stage, the lining for the inside of each of these pieces is cut out and then glued into place. The lining is particularly important for boots made of fragile skins such as snake or eel, for the leather backing will provide most of the strength.

Decorating the pieces

-

2 If the boot is to have any kind of stitched decoration—whether

a simple

pattern, or an elaborate picture such as a yellow rose, an oil derrick, or the state of Texas—this is done before the pieces are assembled. In custom shops, the design is sketched on a paper pattern or stencil and then outlined with a series of small holes. This stencil is laid over each piece and then sprinkled with a marking agent such as white powder, so the design can be followed by someone operating a sewing machine. Factories tend to use computerized sewing machines for this task, with preprogrammed designs, so marking the leather isn't necessary. Any additional colors the design requires are dyed into the leather at this stage.

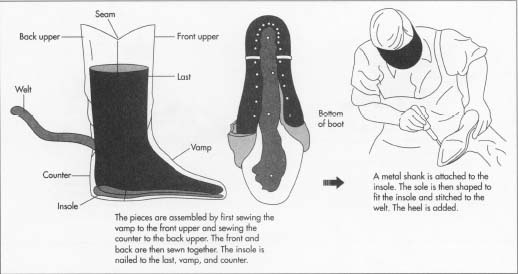

Assembling the top of the boot

- 3 The boot is initially assembled in two halves, front and back. The vamp, the part that covers the top and sides of the foot, is sewn to the front upper; the counter, the part that covers the heel, is sewn to the back upper. Excess leather around the stitching is then trimmed off. A long strip of leather called the welt is then attached to the back of the counter and left hanging there. The welt will be used at a later stage to attach the top of the boot to the sole.

- 4 The front and back halves of the boot are then glued and sewn together. These seams are made first on the inside, so the boot initially takes shape inside out, like a shirt. Leather is, however, harder to work than cotton, and once the seams are made the top of the boot must be soaked in water until the leather is flexible enough to be turned right outside out again. At the end of this stage, the top part of the boot is complete; in a custom shop, the work of a top man would now be done.

Attaching the insole

-

5 The first step in building the bottom of the boot is attaching the

insole to the vamp and the counter. The

insole,

in any shoe or boot, is the part you see when looking down inside it;

it often bears the imprint of the maker's name. A key component

in this part of the process is the last. The

last

is basically a model of a foot—an anatomically accurate version

of a shoetree—which is left inside the boot during the rest of

the manufacturing process. In a factory, lasts are standard sizes and

generally made of molded plastic. In custom shops, they are made of

hardwood and adjusted to the precise shape of an individual's

foot. The workshop of these bootmakers may contain

thousands of lasts, hanging from the walls and ceilings, available for the customers they expect to reorder.

- 6 The insole is first tacked to the last. Then the vamp and the counter are nailed over the insole into the last—first in front, at the toe, and then working around on both sides towards the back. At this point, a stiff piece of leather is inserted at the front of the vamp to reinforce the boot at the toe. The welt, which has been hanging on the back of the counter since the top was first made, is then sewn onto the vamp and the insole. The boot is now almost complete, lacking only a heel and a sole.

Assembling the sole

- 7 Because the welt now binds together the insole, the vamp, and the counter, the nails that tacked the leather to the last are no longer necessary. The nails are removed, but the last remains inside the boot until it is finished. A metal shank is then attached to the insole, to reinforce the high arch; it is held in place by a piece of leather. The sole is shaped to fit the insole and then stitched to the welt. The heel is then nailed on, and then both the heel and the sole are shaped by sanding.

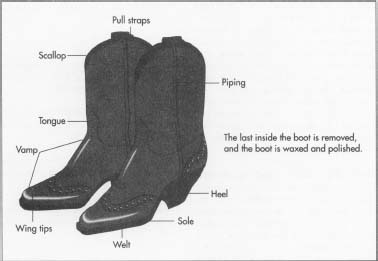

Finishing process

- 8 The finishing process gives the boot its final appearance. The last is removed and a boot tree is used to make fine adjustments in the shape of the boot. Seams are trimmed and stray threads cut short. Final dyes are applied, if necessary, and then the boot is waxed and polished. The boots are checked for quality at this stage, though the standards of quality control vary between factories and custom shops. In a custom shop, how the boot fits an individual customer will distinguish an approved product from one that may need to be reworked or rejected. But with both kinds of manufacturing, the number of stitches per inch is important, as is the quality of the leather, and the strength of the welt.

The Future

The manufacture and marketing of cowboy boots, like western wear in general, experienced dramatic cyclical changes in the 1980s and 1990s. Most bootmakers still remember the consequences of one boom-and-bust period in western wear, the socalled "urban cowboy" fad of the early 1980s, when many companies expanded their production capacity only to see demand plummet. One manufacturer, Justin Industries in Fort Worth, Texas, was only saved from bankruptcy by its investments in other sectors of the economy. Another growth cycle in fashion sales of cowboy boots began at the end of that decade, with actors, rock stars, and fashion models wearing them, as well as politicians and businessmen. Though slower, growth in this cycle lasted longer. In the mid-1990s, some retailers and manufacturers speculated that demand for cowboy boots had peaked, but others saw prospects for growth in the increasing popularity of country music.

Some industry observers feel that new marketing strategies can guarantee continued growth in the sales of cowboy boots, but these cycles may also be what characterizes the new life of this particular commodity. In a world where few people work on horseback anymore, where even most of a typical rancher's day is no longer spent in the saddle, cowboy boots are now largely a fashion item.

Where To Learn More

Books

DeLano, Sharon and David Rieff. Texas Boots. Viking Press, 1981.

Morris, Michele. The Cowboy Life. Simon and Schuster, 1993.

Periodicals

Holly, Susan. "A Country Twist: Business Profiting from Country Fads." Nation's Business, March 1993, pp. 8-13.

McKay, Deidre. "Western Bootmakers Vigorously Scratch Their Niches." Footwear News, July 10, 1994, p. 10.

Sheehy, Sandy Granville. "Boots to Live and Die In." Town and Country Monthly, March 1994, p. 10.

Thomas, Les. "These Boots Are Made for Texas." Southern Living, December 1994, p. 40.

— Douglas Smith