Hearing Aid

Background

The hearing aid is an instrument that amplifies sounds, particularly speech, for people with hearing impairments. It may be worn comfortably behind the ear, in the outer ear, within the ear canal, in the frames of eyeglasses, or against the body or in the clothing. The main elements of the aid are a microphone, an electronic amplifier to make the sound louder, an earphone or receiver, and an ear mold or plastic shell that serves to couple acoustic energy (sound) from the earphone to the eardrum either directly or through plastic tubes. The sound is converted to an electrical signal, amplified, then reconverted to acoustic energy in the inner ear. A battery, the typical power source, can also be contained in the shell.

The microphone and earphone together form a transducer and determine the performance of the aid over a range of frequencies. The adjustment of tone (low and high frequencies) and gain (volume) can be either manual or automatic so that the user can hear enhanced sounds within a comfortable tolerance level.

History

The earliest hearing aids were ear trumpets invented sometime in the 17th century. They were long horns with one large opening at one end and a smaller opening at the other end, which was placed in the ear. The principle behind this instrument being that sound pressure waves entering the large end are condensed into smaller volume, thereby increasing the audible sound pressure.

The first electronic aid was a telephone invented by Alexander Graham Bell in 1876 that converted sound pressure waves to a current and then back to waves. By the 1920s, a more sophisticated telephone-type aid was developed resembling the modern hearing aid with a microphone, electrical circuit, diaphragm, and battery. With the invention of the transistor in 1948, the size and weight of the aid was further greatly reduced. Today, tiny aids placed in the ear canal are barely visible to others, offering great cosmetic appeal to the user. The miniaturization of the hearing aid continues to be an area of research and experimentation. Unfortunately, the smaller the hearing aids become, the greater the manual dexterity required of a user to work the controls.

The Manufacturing

Process

Fabricating a hearing aid takes about two hours. Making hearing aids is a customized process requiring skilled technicians to operate magnification glasses and microscopes in a microminiature manufacturing environment. The tools are generally hand-held and the tasks demand precision movements. The assembler must pay close attention to the wiring diagram and assembly prints so that he or she wires it to produce exact results.

Before fabrication begins, the user is screened by a trained professional. The screening includes a hearing test, and the results are used to create an audiogram covering a variety of parameters. At the screening stage, an impression or mold of the user's outer ear is also taken. The audiogram and the impression are integral to the manufacturing process.

Data entry

- 1 All order data—desired product features and the results of the audiogram—are entered in a computer to determine the operating range for the hearing aid, specifically which levels of amplification are required for the user. For some manufacturers, the computer also selects the electronic circuitry to be used. Typically an order card will be prepared and sent to the production line along with the ear impression. A parts card is also printed and sent to the stock room, where the various components are stored.

Vacuum form of impression

- 2 In this step, a form or reverse copy of the impression of the outer ear and ear canal is produced. A sheet of clear vinyl is placed over the impression; then heat is applied. When cooled, the impression is removed from the vinyl form and trimmed. Next the impression is dipped in hot wax, giving it a smooth, paper-thin coating for the casting step.

Cast of finished impression

- 3 Here a technician will place the impression on a metal plate and place rings around it. A clear liquid colloid or particle suspension is poured into the rings, immersing the impression. The liquid is allowed to cure into a rubbery silicone consistency. Lastly, the impression is pulled out of the gel.

Creating the shell

- 4 The shell or outer casing of the hearing aid is made from this mold. The mold is first heated in 110°F (43°C) water, and air is blown through it to clear away any impurities. At this point, a technician will mix liquid acrylic of equal parts monomer and polymer (for a structurally sound shell) and add the desired pigment to give the shell a pink, tan, or brown color. The technician pours the liquid into the heated colloid mold and after ten seconds, pours off any excess, leaving a thin acrylic shell inside the mold. After 10 minutes of cooling, the technician pulls from the mold a shell that is a perfect replica of the raw impression of the ear canal.

Building the hearing aid into the shell

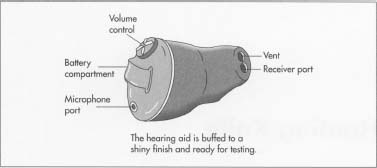

-

5 After a technician grinds off the excess flanges from the shell, he

will add a vent or opening. A small piece of silicon wire shaped to the

vent size is run through the inside of the shell and pulled out. The

technician drills holes into the canal end of the shell for the receiver

tube. After that, the outside of the shell will be buffed to a

smooth, shiny finish. A technician will size the shell for a face plate or flange—the area that will be exposed outside the ear canal—using the vacuum form from the original impression. The plate will be carefully set at the correct angle for the user's ear.

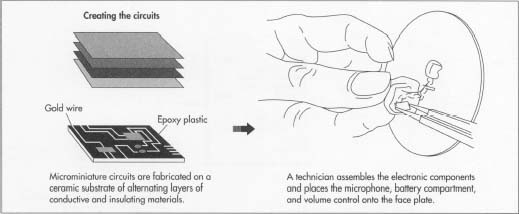

Creating the microminiature circuits

- 6 The components and circuits are run on a ceramic substrate base of various designs. The substrate is made by a screen printing technique that alternates layers of conductive and insulating materials, depending on the engineered design. The conducting layer contains gold and silver, and the insulating layers contain silicon compounds. Between the printing of each layer, the substrate is passed by a conveyor through a furnace, where it bakes for two hours at 850°F (454°C). This seals the layers and creates the color patterns characteristic of printed circuit boards, only on a smaller scale. The various electronic components are bonded by hand to the gold and silver parts on both sides of the substrate. A technician will interconnect the devices using gold wire of .001 inch (.025 mm) thickness. Lastly, the components are sealed in an epoxy paste and heat-hardened.

Assembling the electronic hardware

- 7 Working from the parts card or bill of materials determined at the outset of production, a technician assembles the electronic hardware on the face plate where holes have been drilled for mounting the microphone, amplifier, battery compartment, and volume control, all hand-wired with colors for traceability. The wires are soldered into place. After this, the receiver is mounted into the shell and a preliminary hearing check made on the instrument.

Sealing and finishing

- 8 In the final production steps, the parts are carefully packaged to avoid interferences. A plastic cement is brushed on while the technician performs a listening check to make sure there is no oscillation in the sound quality. Once the cement dries, excess face plate is cut away and the remaining edge ground off with a hand lathe. Finally the aid is buffed and shined to a high gloss and manufacturing is complete. The aid is now ready for final testing.

Quality Control and Testing

Quality control measures are checked throughout production, some of which have been discussed in the process description above. In addition, the shell is given a serial number after it is constructed for tracking purposes. Appearance is important, and a cosmetic check is made as well as a final function check.

Hearing aids are tested using a computerized ANSI (American National Standards Institute) program that analyzes the production parameters and produces a performance chart. A technician reviews the chart on-screen, checking tolerance levels and other specifications. He or she will print a copy of the results and include it with the finished hearing aid.

The Future

The future of hearing aids seems to lie in miniaturization. Today's technology can produce aids the size of a fingertip. Also a recent development, customized digitally programmable aids using microchips found in computers allow users to rapidly switch settings to accommodate different situations. Outdoor events, crowded restaurants, and intimate meetings, each with different sound patterns, can be programmed in the chips. This minimizes the quick adjustments some users must make when they move into a new environment. These custom aids can cost $2,000 each.

Where To Learn More

Books

Levitt, Harry, ed. Recent Advances in Sensory Aids for Hearing Impairment. Diane Publishing Company, 1994.

Neuman, Arlene C. Hearing Aids: Recent Developments. York Press, Inc., 1993.

Pascoe, David P. Hearing Aids — Who Needs Them?: What They Can Do for You, Where to Buy Them, How to Use Them. Big Bend Books, 1991.

Staab, Wayne J. Hearing Aid Handbook. Tab Books, 1978.

Periodicals

Aldersey-Williams, Hugh. "Invisible Hearing Aid Gives Eardrums Good Vibrations." New Scientist, August 1, 1992, p. 18.

Brietzke, C.E. "Listen Up!" Saturday Evening Post, September-October 1993, p. 36, 92-93.

Pierson, John. "Form Plus Function: In-the-Ear Hearing Aids with In-Your-Face Colors." The Wall Street Journal, October 28, 1994, B1.

— Peter Toeg

Thank you

John Adams