Denture

Background

Dentures, or false teeth, are fixed or removable replacements for teeth. Tooth replacement becomes necessary when the tooth and its roots have been irreparably damaged, and the tooth has been lost or must be removed. Dentists have long known that a missing permanent tooth should always be replaced or else the teeth on either side of the space gradually tilt toward the gap, and the teeth in the opposite jaw begin to move toward the space.

There are several standard forms of tooth replacement in modern dentistry. A full denture is made to restore both the teeth and the underlying bone when all the teeth are missing in an arch. A smaller version is the fixed partial denture, also known as a fixed bridge, which can be used if generally healthy teeth are present adjacent to the space where the tooth or teeth have been lost. The partial is anchored to the surrounding teeth by attachment to crowns, or caps, that are affixed to the healthy teeth. A removable partial denture is used to replace multiple missing teeth when there are insufficient natural teeth to support a fixed bridge. This device rests on the soft tissues of the jaws, and is held in place with metal clasps or supports. Dental implants are the latest tooth-replacement technology. They allow prosthetic teeth to be implanted directly in the bones of the jaw.

History

Historically, a variety of materials have been used to replace lost teeth. Animal teeth and pieces of bone were among the earliest of these primitive replacement materials. Two such rudimentary false teeth (probably molars) were found wrapped in gold wire in the ancient Egyptian tomb of El Gigel. In the last few hundred years, artificial teeth have been fashioned from natural substances such as ivory, porcelain, and even platinum. These comparatively crude prototypes of earlier times were carved or forged by hand in an attempt to mimic the appearance and function of natural teeth. Such early denture workmanship is exemplified by George Washington's famous wooden teeth.

Modern technology has offered considerable advances in the materials used to make artificial teeth and improved techniques for affixing them in the mouth. Synthetic plastic resins and lightweight metal alloys have made teeth more durable and natural looking. Better design has resulted in dentures that provide more comfortable and efficient chewing. In the 1980s technology was developed to create the next generation of dentures, which are permanently anchored to the bones in the jaw. These new dentures, known as dental implants, are prepared by specialized dentists called denturists.

Raw Materials

Teeth

Most artificial teeth are made from high quality acrylic resins, which make them stronger and more attractive than was once possible. The acrylic resins are relatively wear-resistant, and teeth made from these materials are expected to last between five and eight years. Porcelain is also used as a tooth material because it looks more like natural tooth enamel. Porcelain is used particularly

Mounting frame

Artificial teeth are seated in a metal and plastic mount, which holds them in place in the mouth during chewing. The mount consists of a frame to provide its form and a saddle-shaped portion that is shaped to conform to the patient's gums and palate. This design allows for comfort and optimizes the dentures' appearance. Frames are typically constructed of metal alloys such as nobilium or chromium. The latest generations of plastic materials used in dentures are virtually indestructible and can be easily adjusted or repaired with a special kit at the dentist's office. These materials are also ultra lightweight and can eliminate problems in patients who are allergic to acrylic materials or who are bothered by the metallic taste left by a metal frame.

Design

Every individual's mouth is different, and each denture must be custom designed to fit perfectly and to look good. The latest methodology used in denture design, known as dentogenics, is based on research conducted in Switzerland in the early 1950s, which developed standards for designing teeth to fit specific smile lines, mouth shapes, and personalities. These standards are based on such factors as mouth size and shape, skull size, age, sex, skin color, and hair color. For example, through proper denture design, patients can be given a younger smile by simply making teeth longer than they normally would be at that patient's age. This rejuvenation effect is possible because a person's teeth wear down over time; slightly increasing the length of the front teeth can create a more youthful appearance.

The Manufacturing

Process

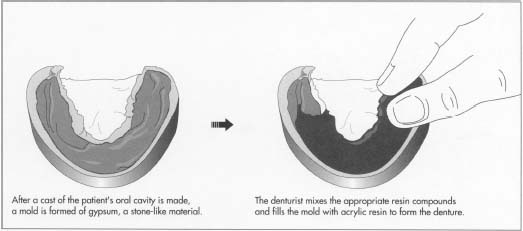

- The manufacturing process begins with a preliminary impression of the patient's mouth, which is usually done in wax. This impression is used to prepare a diagnostic cast. While making the impression, the dentist applies pressure to the soft tissues to simulate biting force and extends the borders of the mold to adjacent toothless areas to allow the dentures to better adapt to the gums.

-

Once an appropriate preliminary cast has been obtained, the final cast

is cast from gypsum, a stone-like product. The final mold is inspected

and approved before using it to manufacture the teeth.

- After the mold has been cast, it is filled with acrylic resin to form the denture. The mold is prepared with a release agent prior to adding the resin to ensure that the hardened acrylic can be easily removed once the process is completed. A sheet of separating film between the acrylic and the model is also helpful in this regard. The denturist then mixes the appropriate resin compounds in liquid form. Upon drying, the resin hardens to a durable finish.

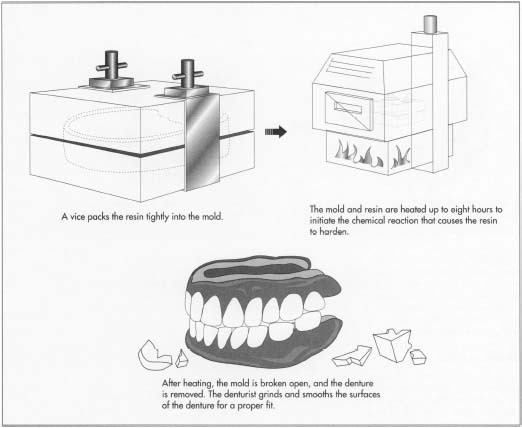

- This resin mixture is packed into the mold, while a vertical vise packs it tightly. At this point the model can be inspected to ensure it is filled properly, and if necessary additional resin can be added. Instead of vice packing, certain types of acrylic may be poured into the mold. This method is more prone to air bubbles than hand packing.

- Once the mold is packed to the denturist's satisfaction, it is heated to initiate the chemical reaction which causes the resin to harden. This part of the process may take up to eight hours.

- After the heating is done and the mold has cooled, the mold is broken apart so the denture may be removed.

- The denture is then put in the model of the patient's mouth to ensure that it fits and that the bite is good. Because of the number of processing steps there may be a slight discrepancy in the fit. Usually just a minor grinding and smoothing of surfaces is all that is necessary to make the denture fit correctly.

At this point, if the denture is the removable type, it is ready for use. Implants require additional preparatory steps before they can be used. The denturist must drill the appropriate holes in the jaw bone and attach an anchor. After three to six months, when the hole has healed and the anchor is set in place, a small second surgical procedure is necessary to expose the implant and connect a metal rod to it that will be used to hold the crown or bridge. Finally, the replacement tooth is attached to the rod, where it is held firmly in place.

Quality Control

Good quality control is critical to ensure the denture fits and looks natural in the patient's mouth. No two dentures will be alike; even two sets of dentures made for the same person will not be exactly alike because they are manufactured in custom molds that must be broken in order to extract the denture. After the molding process is completed, the fine details of the denture are added by hand. This step is necessary to ensure the teeth look natural and fit properly.

The quality of the denture's fit can be controlled in two ways. Relining is a process by which the sides of the denture that contacts the gums are resurfaced. Such adjustments are necessary because the dental impressions used to make dentures cause the gums to move. As a result new dentures may not fit properly. Also, over time bone and gum tissues can shift, altering the fit of the denture. Rebasing is used to refit a denture by replacing or adding to the base material of the saddle. This process is required when the denture base degenerates or no longer extends into the proper gum areas. Most patients require relining or rebasing approximately five to eight years after initial placement of the dentures.

Byproducts/Waste

Denture manufacture generates little waste other than a minimal amount of the gypsum and plaster materials used in mold making. There is also little excess of the acrylic resins used in crafting the teeth and mounts. Large quantities of wasted materials are not generally produced since dentures are hand crafted and not mass produced on a production line.

The Future

Dentistry has shared in many of the successes experienced in other areas of science and medicine. For example, improved surgical techniques have led to the development of implants. Advances in polymer chemistry have resulted in improved resins that are more durable and better looking. However, other materials used in dental techniques still require significant improvement. For example, the adhesives used in bonding artificial constructs to natural teeth research must be improved because a high proportion of these bonding processes are not successful. Similarly, improved resins are necessary to make dentures even more comfortable and longer lasting. As breakthroughs are made in related fields of chemistry, they will be incorporated into denture manufacturing.

Where to Learn More

Books

Goldstein, Ronald. Change Your Smile, 3rd ed. Quintessence Publishing, 1997.

Woodforde, J. The Strange Story of False Teeth. Universe Books, 1968.

Periodicals

Weber, Hans-Peter. "A Tooth for a Tooth." Harvard Health Letter, April 1993, p. 6.

"Dental Implants: How Successful." Healthfacts, January 1996, p. 1.

— Randy Schueller

Thank you

Debra Schreurs

1621 170th Place

Hammond, IN 46324-2104

219-844-8374

Of even more concern to me is how I feel ill when I have my plate in ... I feel much better when it is out for an extended period of time. Could the material that the denture is made out of be making me feel sick? If so, is it possible for the plate to be made out of different material. I don't know what to do!!! Any suggestions would be greatly appreciated! Thank you!