Cotton

Background

Cotton is a shrubby plant that is a member of the Mallow family. Its name refers to the cream-colored fluffy fibers surrounding small cottonseeds called a boll. The small, sticky seeds must be separated from the wool in order to process the cotton for spinning and weaving. De-seeded cotton is cleaned, carded (fibers aligned), spun, and woven into a fabric that is also referred to as cotton. Cotton is easily spun into yarn as the cotton fibers flatten, twist, and naturally interlock for spinning. Cotton fabric alone accounts for fully half of the fiber worn in the world. It is a comfortable choice for warm climates in that it easily absorbs skin moisture. Most of the cotton cultivated in the United States is a short-staple cotton that grows in the American South. Cotton is planted annually by using the seeds found within the downy wool. The states that primarily cultivate cotton are located in the "Cotton Belt," which runs east and west and includes parts of California, Alabama, Arkansas, Georgia, Arizona, Louisiana, Mississippi, Missouri, New Mexico, North Carolina, Oklahoma, South Carolina, Tennessee, and Texas, which alone produces nearly five million bales. Together, these states produce approximately 16 million bales a year, second only to China. Business revenue generated by cotton today is approximately $122.4 billion—the greatest revenue of any United States crop.

The cotton plant is a source for many important products other than fabric. Among the most important is cottonseed, which is pressed for cottonseed oil that is used in commercial products such as salad oils and snack foods, cosmetics, soap, candles, detergents, and paint. The hulls and meal are used for animal feed. Cotton is also a source for cellulose products, fertilizer, fuel, automobile tire cord, pressed paper, and cardboard.

History

Cotton was used for clothing in present-day Peru and Mexico perhaps as long as 5,000 years ago. Also, cotton was grown, spun, and woven in ancient India, China, Egypt, and Pakistan, around 3000 B.C.

Cotton is not native to Western Europe. Around A.D. 800, Arabic traders likely introduced cotton to Spaniards. By the fourteenth century, Mediterranean farmers were cultivating the cotton plant and shipping the fiber to the Netherlands for spinning and weaving. British innovations in the late 1700s include water-powered spinning machinery, a monumental improvement over hand-spinning. An American named Samuel Slater, who worked with British machinery, memorized the plans for a machine spinner and returned to Rhode Island to set up Slater Mill, the first American textile mill to utilize machine spinners. This mill represents the beginning of the U.S. Industrial Revolution, built on the mechanism of the cotton industry.

Two developments spurred the cultivation of American cotton: cotton spinners and the cotton gin. The cotton gin, developed by Eli Whitney in 1793, easily removed tenacious cottonseeds. Southern plantation owners began planting cotton as a result of these innovations, using enslaved labor for harvesting the cotton. Vigorous cotton cultivation in the South using enslaved labor is considered one reason for friction between North and South that led to the Civil War.

Southern cotton was shipped to New England mills in huge quantities. As a result of machine spinning, weaving, and printing, Americans could cheaply purchase calico and it became universally worn. However, labor costs were significant in New England. Mill owners found ways to reduce those costs, first by employing women and immigrants who were often paid poorly, then by employing young children in the factories. After oppressive labor practices were largely halted, many factories moved to the South where labor was cheaper. (Unionizing efforts affected the profits of those mills.) Today, a fair amount of cotton is woven outside the United States where labor is less costly. Polyester, a synthetic, is often used along with cotton, but has little chance of supplanting the natural fiber.

Raw Materials

The materials required to take cotton bolls to spun cotton include cottonseeds for planting; pesticides, such as insecticides, fungicides, and herbicides, to battle disease and harmful insects; and fertilizers to enrich the soil.

There are agricultural requirements for growing cotton in the United States. Cotton has a long growing season (it can be as long as seven months) so it is best to plant cotton early—February in Texas but as late as June in northern cotton-growing states such as Missouri. Cotton should not be planted before the sun has warmed the soil. It performs best in well-drained, crumbly soils that can hold moisture. It can be grown between latitudes of 30° north and 30° south. Good cotton crops require a long, sunny growing season with at least 160 frost-free days and high moisture levels resulting from rainfall or irrigation during the growing season. However, too much rain during harvest or strong winds during picking can damage the open bolls and load the fiber with too much water, which can ruin the cotton in storage. Generally, a cotton farmer must farm about 2,000 acres (20,000 hectares) if the operation is to be economically viable. On average, an acre will produce about 1.5 bales of cotton, or about 750 lb (340 kg).

The Production Process

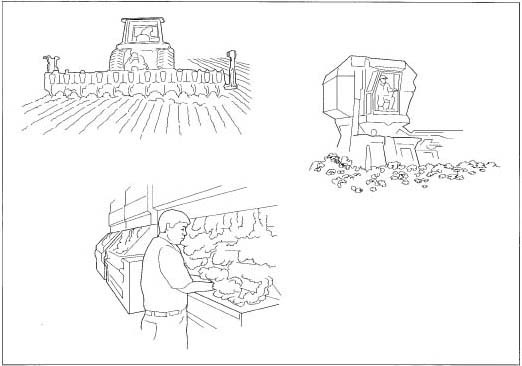

- In spring, the acreage is cleared for planting. Mechanical cultivators rip out weeds and grass that may compete with the cotton for soil nutrients, sunlight, and water, and may attract pests that harm cotton. The land is plowed under and soil is broken up and formed into rows.

- Cottonseed is mechanically planted by machines that plant up to 12 rows at a time. The planter opens a small furrow in each row, drops in seed, covers them, and then packs more dirt on top. Seed may be deposited in either small clumps (referred to as hill-dropped) or singularly (called drilled). The seed is placed 0.75 to 1.25 in (1.9 to 3.2 cm) deep, depending on the climate. The seed must be placed more shallowly in dusty, cool areas of the Cotton Belt, and more deeply in warmer areas.

- With good soil moisture and warm temperature at planting, seedlings usually emerge five to seven days after planting, with a full stand of cotton appearing after about 11 days. Occasionally disease sets in, delaying the seedlings' appearance. Also, a soil crust may prevent seedlings from surfacing. Thus, the crust must be carefully broken by machines or irrigation to permit the plants to emerge.

- Approximately six weeks after seedlings appear, "squares," or flower buds, begin to form. The buds mature for three weeks and then blossom into creamy yellow flowers, which turn pink, then red, and then fall off just three days after blossoming. After the flower falls away, a tiny ovary is left on the cotton plant. This ovary ripens and enlarges into a green pod called a cotton boll.

-

The boll matures in a period that ranges from 55 to 80 days. During this

time, the football-shaped boll grows and moist fibers push the newly

formed seeds outward. As the boll ripens, it remains green. Fibers

continue to expand under the warm sun, with each fiber growing to its

full length—about 2.5 in (6.4 cm)—during three weeks. For

nearly six weeks, the fibers get thicker and layers of cellulose build

up the cell walls. Ten weeks after flowers first appeared, fibers split

the boll apart, and cream-colored cotton pushes forth. The moist fibers

dry in the sun and the fibers collapse and twist together, looking like

ribbon. Each boll contains three to five "cells," each

having about seven seeds embedded in the fiber.

Most steps involved in the production of cotton have been mechanized, including seeding, picking, ginning, and baling. Samples are taken from the bales to determine the quality of the cotton.

Most steps involved in the production of cotton have been mechanized, including seeding, picking, ginning, and baling. Samples are taken from the bales to determine the quality of the cotton. - At this point the cotton plant is defoliated if it is to be machine harvested. Defoliation (removing the leaves) is often accomplished by spraying the plant with a chemical. It is important that leaves not be harvested with the fiber because they are considered "trash" and must be removed at some point. In addition, removing the leaves minimizes staining the fiber and eliminates a source of excess moisture. Some American crops are naturally defoliated by frost, but at least half of the crops must be defoliated with chemicals. Without defoliation, the cotton must be picked by hand, with laborers clearing out the leaves as they work.

- Harvesting is done by machine in the United States, with a single machine replacing 50 hand-pickers. Two mechanical systems are used to harvest cotton. The picker system uses wind and guides to pull the cotton from the plant, often leaving behind the leaves and rest of the plant. The stripper system chops the plant and uses air to separate the trash from the cotton. Most American cotton is harvested using pickers. Pickers must be used after the dew dries in the morning and must conclude when dew begins to form again at the end of the day. Moisture detectors are used to ensure that the moisture content is no higher than 12%, or the cotton may not be harvested and stored successfully. Not all cotton reaches maturity at the same time, and harvesting may occur in waves, with a second and third picking.

- Next, most American cotton is stored in "modules," which hold 13-15 bales in water-resistant containers in the fields until they are ready to be ginned.

- The cotton module is cleaned, compressed, tagged, and stored at the gin. The cotton is cleaned to separate dirt, seeds, and short lint from the cotton. At the gin, the cotton enters module feeders that fluff up the cotton before cleaning. Some gins use vacuum pipes to send fibers to cleaning equipment where trash is removed. After cleaning, cotton is sent to gin stands where revolving circular saws pull the fiber through wire ribs, thus separating seeds from the fiber. High-capacity gins can process 60, 500-lb (227-kg) bales of cotton per hour.

- Cleaned and de-seeded cotton is then I 0 compressed into bales, which permits economical storage and transportation of cotton. The compressed bales are banded and wrapped. The wrapping may be either cotton or polypropylene, which maintains the proper moisture content of the cotton and keeps bales clean during storage and transportation.

- Every bale of cotton produced in the United States must be given a gin ticket and a warehouse ticket. The gin ticket identifies the bale until it is woven. The ticket is a bar-coded tag that is torn off during inspection. A sample of each bale is sent to the United States Department of Agriculture (USDA) for evaluation, where it is assessed for color, leaf content, strength, fineness, reflectance, fiber length, and trash content. The results of the evaluation determine the bale's value. Inspection results are available to potential buyers.

- After inspection, bales are stored in a carefully controlled warehouse. The bales remain there until they are sold to a mill for further processing.

Quality Control

Cotton growing is a long, involved process and growers must understand the requirements of the plant and keep vigilant lookout for potential problems. Pests must be managed in order to yield high-quality crops; however, growers must use chemicals very carefully in order to prevent damage to the environment. Defoliants are often used to maximize yield and control fiber color. Farmers must carefully monitor moisture levels at harvesting so bales will not be ruined by excess water during storage. Soil tests are imperative, since too much nitrogen in the soil may attract certain pests to the cotton.

Expensive equipment such as cotton planters and harvesters must be carefully maintained. Mechanical planters must be set carefully to deposit seed at the right depth, and gauge wheels and shoes must be corrected to plant rows at the requisite spot. Similarly, improperly adjusted machinery spindles on harvesting machines will leave cotton on the spindle, lowering quality of the cotton and harvesting efficiency. A well-adjusted picker minimizes the amount of trash taken up, rendering cleaner cotton.

Byproducts/Waste

There is much discussion regarding the amount of chemicals used in cotton cultivation. Currently, it is estimated that growers use, on average, 5.3 oz (151 g) of chemicals to produce one pound of processed cotton. Cotton cultivation is responsible for 25% of all chemical pesticides used on American crops. Unfortunately, cotton attracts many pests (most notably the boll weevil) and is prone to a number of rots and spotting, and chemicals are used to keep these under control. There are concerns about wildlife poisoning and poisons that remain in the soil long after cotton is no longer grown (although no heavy metals are used in the chemicals). As a result, some farmers have turned to organic cotton growing. Organic farming utilizes biological control to rid cotton of pests and alters planting patterns in specific ways to reduce fungicide use. While this method of cultivation is possible, an organically grown crop generally yields less usable cotton. This means an organic farmer must purchase, plant, and harvest more acreage to yield enough processed cotton to make the crop lucrative, or reduce costs in other ways to turn a profit. Increasingly, state university extension services are working with cotton farmers to reduce chemical use by employing certain aspects of biological control in order to reduce toxins that remain in the land and flow into water systems.

Where to Learn More

Books

Daniel, Pete. Breaking the Land. Champaign, IL: University of Illinois Press, 1987.

Johnson, Guinevere. Cotton. Let's Investigate Series. Mankato, MN: The Creative Co., 1999.

Other

The Cotton Pickin' Web. http://ipmwww.ncsu.edu/CottonPickin (January 2, 2001).

Land of Cotton Online Newsmagazine for the Cotton Industry. http://www.landofcotton.com (January 2, 2001).

National Cotton Council of America. Education Materials. http://www.cotton.org/ncc/education (January 2, 2001).

The Organic Cotton Site. http://www.sustainablecotton.org . (January 2, 2001).

— Nancy E.V. Bryk

What do they mean? I realize it refers to weight. But of what?

Ounces per yard of material? Then how is that manufactured to produce whatever it is they are referring to?

Thank you.