Tunnel

Background

A tunnel is an underground or underwater passage that is primarily horizontal. Relatively small-diameter ones carry utility lines or function as pipelines. Tunnels that transport people by rail or by automobile often comprise two or three large, parallel passages for opposite-direction traffic, service vehicles, and emergency exit routes.

The world's longest tunnel carries water 105 mi (170 km) to New York City from the Delaware River. The lengthiest person-carrying tunnel is the Seikan Railroad Tunnel. It is a 33-mi (53-km) long, 32-ft (9.7-m) diameter railroad connection between Japan's two largest islands, Honshu and Hokkaido.

One of the most anticipated tunnels was the Channel Tunnel. Completed in 1994, this tunnel connects Great Britain to Europe through three, 31-mi (50-km) long tunnels (two one-way and one service tunnel). Twenty-three miles (37 km) of this tunnel are underwater.

History

Tunnels were hand-dug by several ancient civilizations in the Indian and Mediterranean regions. In addition to digging tools and copper rock saws, fire was sometimes used to heat a rock obstruction before dousing it with water to crack it apart. The cut-and-cover method—digging a deep trench, constructing a roof at an appropriate height within the trench, and covering the trench above the roof (a tunneling technique still employed today)—was used in Babylon 4,000 years ago.

The first advance beyond hand-digging was the use of gunpowder to blast a 515-ft (160-m) long canal tunnel in France in 1681. The next two major advances came about 1850. Nitroglycerine (stabilized in the form of dynamite) replaced the less powerful black powder in tunnel blasting. Steam and compressed air were used to power drills to create holes for the explosive charges. This mechanization eventually replaced the manual process made famous by John Henry, the "steel-driving man," who swung a 10-lb (4.4-kg) sledge hammer with each hand for 12 hours a day, pounding steel chisels as deep as 14 ft (4.2 m) into solid rock.

Between 1820 and 1865, British engineers Marc Brunel and James Greathead developed several models of a tunneling shield that enabled them to construct two tunnels under the Thames River. A rectangular or circular enclosure (the shield) was divided horizontally and vertically into several compartments. A man working in each compartment could remove one plank at a time from the face of the shield, dig ahead a few inches, and replace the plank. When space had been dug away from the entire front surface, the shield was pushed forward, and the digging process was repeated. Workers at the rear of the shield lined the tunnel with bricks or cast iron rings.

In 1873, American tunneler Clinton Haskins kept water from seeping into a railroad tunnel under construction below the Hudson River by filling it with compressed air. The technique is still used today, although it presents several dangers. Workers must spend time in decompression chambers at the end of their shift—a requirement that limits emergency exits from the tunnel. The pressure within the tunnel must be carefully balanced with the surrounding earth and water pressure; an imbalance causes the tunnel either to collapse or burst (which subsequently allows flooding).

Soft soil is prone to collapse and it can clog digging equipment. One way to stabilize the soil is to freeze it by circulating coolant through pipes embedded at intervals throughout the area. This technique has been used in the United States since the early 1900s. Another stabilization and waterproofing technique—widely used since the 1970s—is to inject grout (liquid bonding agent) into soil or fractured rock surrounding the tunnel route.

Shotcrete is a liquid concrete that is sprayed on surfaces. Invented in 1907, it has been used as both a preliminary and a final lining for tunnels since the 1920s.

In 1931, the first drilling jumbos were devised to dig tunnels that would divert the Colorado River around the construction site for Hoover Dam. These jumbos consisted of 24-30 pneumatic drills mounted on a frame welded to the bed of a truck. Modern jumbos allow a single operator to control several drills mounted on hydraulically controlled arms. In 1954, while building diversion tunnels for construction of a dam in South Dakota, James Robbins invented the tunnel boring machine (TBM), a cylindrical device with digging or cutting heads mounted on a rotating front face that grinds away rock and soil as the machine creeps forward. Modern TBMs are customized for each project by matching the types and arrangement of the cutting heads to the site geology; also, the diameter of TBM must be equal to the diameter of the designed tunnel (including its lining).

Raw Materials

Materials used in tunnels vary with the design and construction methods chosen for each project. Grout used to stabilize soil or fill voids behind the tunnel lining may contain various materials, including sodium silicate, lime, silica fume, cement, and bentonite (a highly absorbent volcanic clay). Bentonite-and-water slurry is also used as a suspension and transportation medium for muck (debris excavated from the tunnel) and as a lubricant for objects being pushed through the tunnel (e.g., TBMs, shields). Water is used to control dust during drilling and after blasting, which is often done with a low-freezing gelatine explosive. Water-and-salt brine or liquid nitrogen are common refrigerants for stabilizing soft ground by freezing. The most common modern lining material, concrete reinforced by either steel or fiber, may be sprayed on, cast in place, or prefabricated in panels.

Choice of method

A tunnel's construction method is determined by several factors, including geology, cost, and potential disruption of other activities. Different methods may be used on individual tunnels that are part of the same larger project; for example, four separate methods are being used on portions of Boston's Central Artery/Tunnel project.

The Manufacturing Process

Preparing

- 1 Site geology is evaluated by examining surface features and subsurface core samples. A pilot tunnel about one-third the diameter of the planned main tunnel may be constructed along the entire route to further evaluate the geology and to test the selected construction method. The pilot tunnel may run alongside the main tunnel's path and eventually be connected to it at intervals to provide ventilation, service access, and an escape route. Or the pilot tunnel may be enlarged to produce the main tunnel.

- 2 If soil stabilization is required, it may be done by injecting grout through small pipes placed in the ground at intervals. Alternatively, a refrigerant may be circulated through pipes embedded in the ground to freeze the soil.

Mining

-

3 There are seven different methods used to remove material from the tunnel path. The first is the immersed tube method. Workers prepare an underwater tunnel site by digging a trench at the bottom of the waterway. Steel or reinforced concrete sections of tunnel shell are constructed on dry land. Each section may be several hundred feet (100 m or more) long. The ends of the section are sealed, and the section is floated to the tunnel site. The section is tied to anchors adjacent to the trench, and ballast tanks built into the section are flooded. As the section sinks, it is guided into place in the trench. The section is connected to the adjoining, previously placed section, and the plates sealing that end of each section are removed. A rubber seal between the two sections ensures a watertight connection.

In the cut-and-cover method workers dig a trench large enough to contain the tunnel and its shell. A box-shaped tube is constructed, often by in-place casting of reinforced concrete. In certain types of soil or in close proximity to other structures, tunnel walls may be built before digging begins in order to keep the trench from collapsing during excavation. This may be done by driving steel sheets into the ground or building a slurry wall (a deep trench that is filled with watery clay as dirt is removed). When the desired size is attained for a section of wall, a cage of steel reinforcing rods is lowered into it and concrete is pumped in to displace the wet-clay slurry. As digging progresses enough for the excavation machinery to be below grade, temporary surface panels may be laid across the trench to allow traffic to move across it. When the tunnel shell has been completed, it is covered by replacing excavated soil.

The third method is the top-down method. A parallel pair of walls are embedded into the ground along the tunnel's route by driving steel sheet piles or constructing slurry walls. A trench is dug between the walls to a depth equal to the planned distance from the surface to the inside of the tunnel roof. The tunnel roof is formed between the walls by framing and pouring reinforced concrete on the bottom of the shallow trench. After the tunnel roof has cured, it is covered with a waterproofing membrane and excavated soil is replaced above it. Conventional excavating machinery, such as a front-end loader, is used to dig out the soil between the diaphragm walls and under the tunnel roof. When sufficient depth has been reached, a reinforced concrete floor is poured to complete the tunnel shell.

With the drill-and-blast method a drilling jumbo is used to drill a predetermined pattern of holes in the rock along the tunnel's path. Carefully planned charges of dynamite are inserted in the drilled holes. The charges are detonated in a sequence designed to break away material from the tunnel's path without unduly damaging the surrounding rock. Air is circulated through the blast area to remove explosion gases and dust. Rubble dislodged by the blast is hauled away. Pneumatic drills and hand tools are used to smooth the surface of the blasted section and remove loose pieces of rock.

The Eurotunnel.

The Eurotunnel.Construction on the English Channel Tunnel between England and France, a dream for centuries envisioned and encouraged by Napoleon, was begun in 1987. Originally referred to as the Chunnel and now known as the Eurotunnel, it was completed in 1994 at a cost of $13 billion. The two rail tunnels (one for northbound and one for southbound traffic) and one service tunnel are each 31 mi (50 km) in length and have an average depth of 150 ft (46 m) under the seabed. It is the first physical link between Britain and the European continent. Passenger rail service is provided, as well as the ferrying of automobiles and trucks. Travel times from London to Paris have been reduced from more than five hours (over sea) to three hours via the Eurotunnel.

The Seikan Tunnel in Japan was placed in service in 1988. The 33mi-(53km-)long tunnel connects the northern tip of Japan's main island of Honshu with the island of Hokkaido, passing under the Tsugaru Strait. The Seikan Tunnel is the world's longest submarine tunnel, involving excavation 330 ft (100 m) below the seabed across a strait where the sea is up to 460 ft (140 m) in depth.

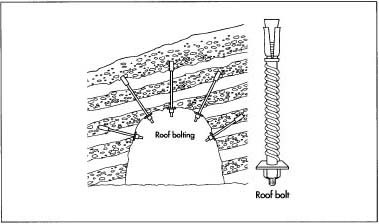

It is usually necessary to stabilize and reinforce the surface of the newly blasted section with a preliminary lining. One technique involves inserting a series of steel ribs connected by wood or steel braces. Another technique, called the new Austrian tunneling method (NATM), involves spraying the surface with a few inches (several centimeters) of concrete. In appropriate geologic conditions,

this "shotcrete" lining may be supplemented by inserting long steel rods (rock bolts) into the rock and tightening nuts against steel plates surrounding the head of each bolt. Shield tunneling.

Shield tunneling.A fifth method to remove material from the tunnel is the shield driving or tunnel jacking method. Some tunnels are still dug using a Greathead-style shield. The top of the shield extends beyond the sides and bottom, providing a protective roof for workers digging in advance of the shield. The leading edge of the shield top is sharp so it can cut through the soil. Excavation may be done by hand or with power tools. Excess material is passed back through the shield on a convey or belt, loaded into carts, and hauled out of the tunnel. When workers have dug out material in front of the shield as far as the top extends, jacks at the rear of the shield are braced against the most recently installed section of tunnel lining. Activating the jacks pushes the shield forward so workers can begin digging another section. After the shield has moved forward, the jacks are retracted, and steel or reinforced concrete ring segments are bolted into place to form a section of permanent lining for the tunnel.

Tunnel jacking is a similar technique, but the shield being driven through the ground is actually a prefabricated section of tunnel lining.

In the parallel drift method a series of parallel, horizontal holes (drifts) are bored using microtunneling machinery (microtunnels are too small for human miners to work inside of) such as augers or small versions of TMBs. These drifts are filled; for example, steel pipes may be driven into them and then the pipes packed with grout. The filled drifts form a protective arch around the tunnel path. Excavation machinery is used to remove the soil from inside the arch.

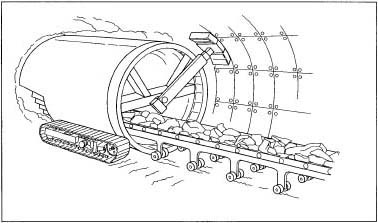

The final method is the tunnel boring machine method. The types and arrangement of cutting devices on the face of the TBM are determined by the geology at the tunnel site. The face slowly rotates and grinds away the rock and soil in front of it (e.g., the TBMs used to build the Channel Tunnel could rotate up to 12 revolutions per minute in optimal soil). The TBM is constantly pushed forward to keep the face in contact with its target. Forward pressure may be exerted by jacks at the rear of the TBM pushing against the most recently installed section of tunnel lining. Alternatively, gripper arms may extend outward from the sides of the TBM and push against rocky tunnel walls to hold the machine in place while the face is pushed forward. Muck is passed through holes in the face and carried by conveyor belt to the rear of the TBM, where it drops into carts that transport it out of the tunnel. Bentonite may be pumped through the TBM face to make the soil surface more workable and to carry away the muck. Some TBMs are equipped at the rear with robotic arms that position and attach segments of tunnel lining as soon as the machine has moved forward

a sufficient distance. In other cases, the NATM is used to create a preliminary lining as the TBM progresses. Roof bolts made of steel are secured to rock in order to support the top of the tunnel.

Roof bolts made of steel are secured to rock in order to support the top of the tunnel.Especially in cases where two TBMs dig toward each other from opposite ends of a tunnel, it may be too difficult or expensive to remove them when the digging is completed. As it nears the end of its mission, the TBM may be steered away from the tunnel's path to dig a short spur in which it is permanently sealed.

Final lining

-

4 In some cases, the final lining is placed during the excavation process. Two examples are TBMs that install lining segments and prefabricated tunnels that are jacked into place. In other cases, a final lining must be constructed after the entire tunnel is excavated. One option is to pour a reinforced concrete lining in place. Slipforming is an efficient technique in which a section of form is slowly moved forward as the concrete is poured between it and the tunnel wall; the concrete hardens quickly enough to support itself by the time the form moves on.

A second option is to install segments of preformed concrete or steel lining, much as some TBMs do. Lining segments are constructed so that several of them can be joined to form a complete ring a few feet (a meter or two) wide. Once a ring has been bolted into place, grout is injected between it and the tunnel wall.

A third option is to spray a layer of shotcrete several inches (70 mm or more) thick onto the tunnel walls. One or two layers of wire mesh might be placed first to reinforce the shotcrete, or reinforcing fibers might be added to the concrete mixture to increase its strength.

Byproducts/Waste

Sometimes the earth removed from a tunnel is simply discarded into a landfill. In other cases, however, it becomes raw material for other projects. For example, it may be used to form the base course for an approach roadway or to create roadway embankments for wider shoulders or erosion control.

Quality Control

Besides maintaining ground stability around the tunnel and ensuring structural integrity of the tunnel lining, proper alignment of the excavation path must be achieved. Two valuable tools are global positioning system (GPS) sensors that receive precise locational data via satellite signals and guidance systems that project and detect a laser beam within the tunnel.

The Future

Exploration methods, materials, and machinery are possible areas of improvement. Sound waves transmitted through the earth can now generate a virtual CAT scan of the tunnel path, reducing the need to drill core samples and pilot tunnels. Some examples of materials research involve cutting tools that are more effective and durable, concrete with more precisely controlled hardening rates, and better processes for modifying soil to make it easier to cut, dig, or remove. Recent developments in machine technology include multiple-headed TBMs that can bore two or three parallel tunnels simultaneously and a TBM that can turn a corner up to 90° while cutting. Better remote control capabilities for digging machinery would improve safety by reducing the amount of time people have to be underground during the digging process.

Where to Learn More

Periodicals

Burroughs, Dan, et al. "Depressing Traffic Top-Down." Civil Engineering (January 1994): 62.

Campo, David W., and Donald P. Richards. "Tunneling Beneath Cairo." Civil Engineering (January 2000): 36.

Iseley, Tom. "Microtunneling MARTA." Engineering (December 1991): 50.

O'Connor, Leo. "Tunneling Under the Channel." Mechanical Engineering (December 1993): 60.

Other

The Cumberland Gap Tunnel. http://www.efl.fha.dot.gov/cumgap/tunnel.htm (January 2000).

"A Short History of Tunnelling." http://pisces.sbu.ac.uk/BE/CECM/Civ-eng/tunhist.html (January 2000).

"Tunnel Jacking." Central Artery/Tunnel Project. http://www.bigdig.com (January 2001).

— Loretta Hall