Suture

Background

A surgical suture is used to close the edges of a wound or incision and to repair damaged tissue. There are many kinds of sutures, with different properties suitable for various uses. Sutures can be divided into two main groups: absorbable and non-absorbable. An absorbable suture decomposes in the body. It degrades as a wound or incision heals. A non-absorbable suture resists the body's attempt to dissolve it. Non-absorbable sutures may be removed by a surgeon after a surface incision has healed.

Sutures are made from both man-made and natural materials. Natural suture materials include silk, linen, and catgut, which is actually the dried and treated intestine of a cow or sheep. Synthetic sutures are made from a variety of textiles such as nylon or polyester, formulated specifically for surgical use. Absorbable synthetic sutures are made from polyglycolic acid or other glycolide polymers. Most of the synthetic suture materials have proprietary names, such as Dexon and Vicryl. The water-resistant material Goretex has been used for surgical sutures, and other sutures are made from thin metal wire.

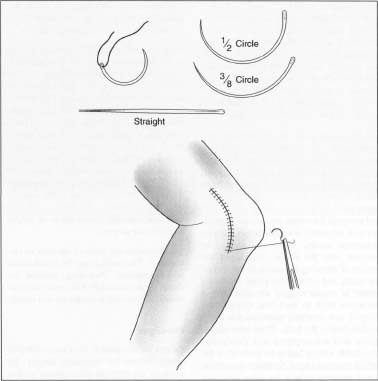

Sutures are also classified according to their form. Some are monofilaments, that is, consisting of only one thread-like structure. Others consist of several filaments braided or twisted together. Surgeons choose which type of suture to use depending on the operation. A monofilament has what is called low tissue drag, meaning it passes smoothly through tissue. Braided or twisted sutures may have higher tissue drag, but are easier to knot and have greater knot strength. Braided sutures are usually coated to improve tissue drag. Other sutures may have a braided or twisted core within a smooth sleeve of extruded material. These are known as pseudo-monofilaments. A suture can also be classified according to its diameter. In the United States, suture diameter is represented on a scale descending from 10 to 1, and then descending again from 1-0 to 12-0. A number 9 suture is 0.0012 in (0.03 mm) in diameter, while the smallest, number 12-0, is smaller in diameter than a human hair.

Suture manufacturing comes under the regulatory control of the Food and Drug Administration (FDA) because sutures are classified as medical devices. Manufacturing guidelines and testing for the industry is provided by a non-profit, non-governmental agency called United States Pharmacopeia, located in Rockville, Maryland.

History

Physicians have used sutures for at least 4,000 years. Archaeological records from ancient Egypt show that Egyptians used linen and animal sinew to close wounds. In ancient India, physicians used the heads of beetles or ants to effectively staple wounds shut. The live creatures were affixed to the edges of the wound, which they clamped shut with their pincers. Then the physician cut the insects' bodies off, leaving the jaws in place. Other natural materials doctors used in ancient times were flax, hair, grass, cotton, silk, pig bristles, and animal gut.

Though the use of sutures was widespread, sutured wounds or incisions often became infected. Nineteenth century surgeons preferred to cauterize wounds, an often ghastly process, rather than risk the patient's death from infected sutures. The great English physician Joseph Lister discovered disinfecting techniques in the 1860s, making surgery much safer. Lister soaked catgut suture material in phenol making it sterile, at least on the outside. Lister spent over 10 years experimenting with catgut, to find a material that was supple, strong, sterilizable, and absorbable in the body at an adequate rate. A German surgeon made advances in the processing of catgut early in the twentieth century, leading to a truly sterile material.

Catgut was the staple absorbable suture material through the 1930s, while physicians used silk and cotton where a non-absorbable material was needed. Suture technology advanced with the creation of nylon in 1938 and of polyester around the same time. As more man-made textiles were developed and patented for suture use, needle technology also advanced. Surgeons began using an atraumatic needle, which was pressed or crimped onto the suture. This saved the trouble of threading the needle in the operating room, and allowed the entire needle diameter to remain roughly the same size as the suture itself. In the 1960s, chemists developed new synthetic materials that could be absorbed by the body. These were polyglycolic acid and polylactic acid. Previously, absorbable sutures had to be made from the natural material catgut. Synthetic absorbable suture material is now far more prevalent than catgut in United States hospitals.

The FDA began requiring approval of new suture material in the 1970s. A Medical Device Amendment was added to the FDA in 1976, and suture manufacturers have been required to seek pre-market approval for new sutures since that time. Manufacturers must comply with specific Good Manufacturing Practices, and guarantee that their products are safe and effective. Patents for new suture materials are granted for 14 years.

Raw Materials

Natural sutures are made of catgut or reconstituted collagen, or from cotton, silk, or linen. Synthetic absorbable sutures may be made of polyglycolic acid, a glycolide-lactide copolymer; or polydioxanone, a copolymer of glycolide and trimethylene carbonate. These different polymers are marketed under specific trade names. Synthetic nonabsorbable sutures may be made of polypropylene, polyester, polyethylene terephthalate, polybutylene terephthalate, polyamide, different proprietary nylons, or Goretex. Some sutures are also made of stainless steel.

Sutures are often coated, especially braided or twisted sutures. They may also be dyed to make them easy to see during surgery. Only FDA approved dyes and coatings may be used. Some allowable dyes are: logwood extract, chromium-cobalt-aluminum oxide, ferric ammonium citrate pyrogallol, D&C Blue No. 9, D&C Blue No. 6, D&C Green No. 5, and D&C Green No. 6. The coatings used depend on whether the suture is absorbable or nonabsorbable. Absorbable coatings include Poloxamer 188 and calcium stearate with a glycolide-lactide copolymer. Nonabsorbable sutures may be coated with wax, silicone, fluorocarbon, or polytetramethylene adipate.

Suture needles are made of stainless or carbon steel. The needles may be nickel-plated or electroplated. Packaging material includes water-resistant foil, such as aluminum foil, as well as cardboard and plastic.

Design

Sutures are designed to meet many different needs. Sutures for abdominal surgery, for example, are different from sutures used in cataract surgery. Since no one type of suture is ideal for every operation, surgeons and medical designers have come up with sutures with varying qualities. One may be more absorbable but less flexible, while another is exceedingly strong but perhaps somewhat difficult to knot. This gives surgeons many options. Designers of a new suture have to take into account many factors. The rate the suture degrades is important, not only along the length of the suture but at the knot. Some sutures need to be elastic, so that they will stretch and not break. Others need to hold tight. Suture manufacturers use specially designed machines to test and study sutures. New suture designs are also tested by subjecting them to chemical tests, such as soaking them in various solutions, and testing on animals.

The Manufacturing

Process

The manufacturing of sutures for surgical use is not very different from the production

- The first step in suture manufacturing is to produce the raw polymer. Workers measure the chemicals making up the polymer into a chemical reactor. In the reactor, the chemicals are combined (polymerized), forced through a die, and discharged as tiny pellets.

- Next workers empty the pellets into an extrusion machine. The extruder has a nozzle, looking something like a shower head, pierced with many tiny holes. The machine melts the polymer, and the liquid flows through the tiny holes, forming many individual filaments.

- After extrusion, the filaments are stretched between two rollers. The filaments stretch to as much as five times their original length.

- Some sutures are produced as monofilaments. Others are braided or twisted. To braid the suture, the extruded monofilament is wound onto bobbins, and the bobbins are loaded onto an automatic braiding machine. Such a machine is typically of an old design that might also be used in the manufacture of textiles for fabric. The number of filaments braided together depends on the width of the suture made for the particular batch. A very fine suture might braid 20 filaments, a medium width hundreds, and a very thick suture might braid thousands of filaments. The braiding machine produces one continuous strand of braided material. It works very slowly, and typically the machine is set to run for as long as four weeks at a time. The process is almost entirely automatic. Workers in the plant inspect the equipment for break-downs and reload empty bobbins, but generally the process requires little man-power.

- After braiding, the suture undergoes several stages of secondary processing. Non-braided sutures will also go through these steps after extrusion and initial stretching. Workers load the material onto another machine that performs another stretching and pressing operation. Unlike the first stretching, this step might take only a few minutes, and adds to the length of the material by only about 20%. The suture passes over a hot plate, and any lumps, snags, or imperfections are ironed out.

- Next, workers pass the suture through an annealing oven. The annealing oven subjects the suture to high heat and tension, which actually orders the crystalline structure of the polymer fiber into a long chain. This step may take several minutes or several hours, depending on the type of suture being made.

- After annealing, the suture may be coated. The coating material varies depending on what the suture is made of. The suture passes through a bath of coating material, which may be in solution or may be in a thick, paste-like state called a slurry.

- All the major manufacturing steps at the processing plant are complete at this point. Now the quality assurance workers test the batch of suture for various qualities. These workers make sure the suture conforms to the proper diameter, length, and strength, look for physical defects, and check the dissolvability of an absorbable suture in animal and test-tube tests. If the batch passes all the tests, it is shipped to a finishing plant.

- The surgical needles are made at another plant, and also shipped to the finishing plant. The needles are made of fine steel wire, and drilled lengthwise. Workers at the finishing plant cut the suture into standard lengths. The length of suture is mechanically inserted into the hollow in the needle, and the needle is crimped onto the fiber. This process is called swaging.

- Next, the suture and attached needle are inserted into a foil packet and sterilized. Sterilization differs according to the suture material. Some sutures are sterilized with gamma radiation. In this case, the sutures are packaged completely. The whole package, typically a sealed foil pack inside a cardboard box, is set on a conveyor belt. The sealed package passes under pencil-shaped lenses emitting gamma radiation. This kills all microbes. The suture is now ready for shipment. Some suture material cannot withstand gamma radiation, and it is sterilized in a different process. The suture and needles are packaged in a foil pack, but the pack is left open. The packages move into a gas chamber, which is then filled with ethylene oxide gas. Then the foil packs are sealed, inserted into boxes or other packaging, and readied for shipment.

Quality Control

Sutures, as medical devices, are subject to strict quality control. All the raw materials that arrive at the manufacturing plant are tested to make sure they are what they are supposed to be. Each batch of sutures is tested after the main manufacturing steps for a variety of physical characteristics such as diameter and strength. The suture industry has developed an array of sophisticated instruments for testing special suture characteristics such as knot security and tissue drag. Tests for diameter, length, and strength of the suture are also performed at the finishing plant. The finishing plant must also test how well the needle is attached to the suture. Guidelines for suture quality control are laid down by the independent organization United States Pharmacopeia.

The Future

New sutures are being developed all the time, to better respond to particular surgical needs. While not replacing sutures, scientists have also devised alternative methods of wound closure. The first surgical stapler was invented in 1908, but stapler technology developed considerably in the 1990s. Precise machines are able to place absorbable staples, as thin as four human hairs, beneath the top layer of skin to secure an incision with minimal scarring. A related device, first tested on patients in the United States in 2000, is a surgical zipper. A surgeon can place the zipper over a straight incision and zip the wound closed, eliminating the need for suturing. After the wound heals, the patient can wash the zipper off in the shower. Another surgical closure method that is still evolving is surgical glue. Surgical glue is less painful than sutures if a wound must be closed without anaesthetic. The glue may leave less scarring in some cases, and be easier to care for post-operatively.

Where to Learn More

Books

Mukherjee, D. P. "Sutures." In Polymers: Biomaterials and Medical Applications. New York: John Wiley & Sons, 1989.

Planck, H., M. Dauner, and M. Renardy, eds. Medical Textiles for Implantation. Berlin: Springer-Verlag, 1990.

Periodicals

"Dermabond 'Super Glue' Receives Mixed Reviews." Dermatology Times (October 1999): 1.

Mraz, Stephen J. "From the Jaws of Ants to Absorbable Staples." Machine Design (12 January 1995):70ff.

"Zip-it-y Doo Dah." Nursing (May 2000): 62.

Angela Woodward

I am tanks from you for this article.it is very short but very nice for learning.

Yes the sutures could still be in his system forever. Depending on what type of material the sutures were made from, the body might never absorb them.

Since the sutures were blue, they most likely were made of UHMWPE (Dyneema), polyester, or polypropylene. None of these materials are bioresorable, as they are no different from plastic soda bottles or plastic bags.